In this post, we’ll solve an important conceptual question from Spark Ignition (SI) Engines that often appears in exams like SSC JE, RRB JE, and State Engineering Services.

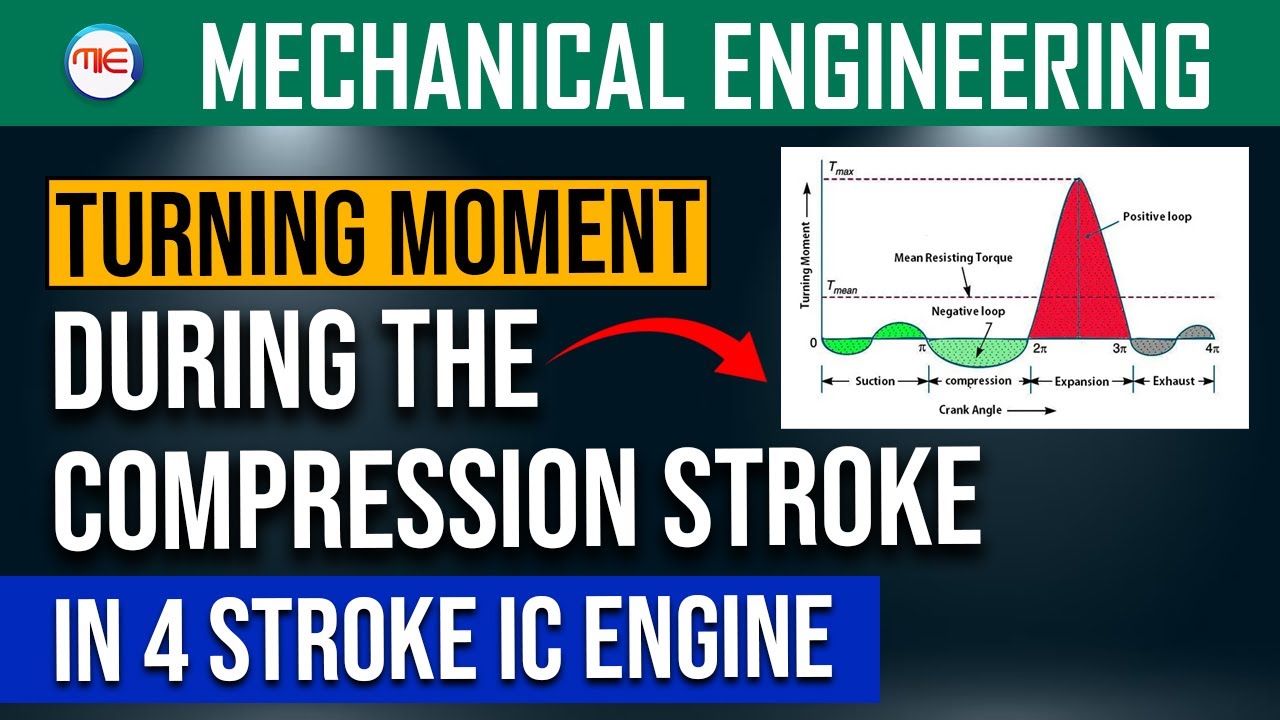

I’ve explained the concept with diagrams and real-life examples in my video.

(a) Increase

In an S.I. (Spark Ignition) engine, the fuel-air mixture is compressed before ignition.

When compression ratio increases:

End-gas temperature and pressure rise sharply.

Higher temperature and pressure reduce the self-ignition delay period.

As a result, the unburnt end-gas may auto-ignite before the flame front arrives, causing knocking.

Knocking in SI engines is primarily influenced by:

Higher compression ratio → Higher end-gas temperature → Increased knocking tendency.

Loss of power

Engine overheating

Piston and valve damage

Reduced engine life

Exam Tip:

In SI engines → Higher compression ratio → Knocking increases.

In CI (Diesel) engines → Higher compression ratio → Knocking decreases.

Makeiteasy

.jpeg)

Leave a Comment