| S.No | Question | Option A | Option B | Option C | Option D | Answer | Solution | Comments | Status | Action |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | The value of sensible heat factor quite common in air-conditioning practice in a normal dry climate is: | 0.35 to 0.40 | 0.45 to 0.55 | 0.65 to 0.70 | 0.75 to 0.80 | d | Comments | Active | ||

| 2 | On psychrometric chart, OC line represents |

Dehumidifying | Heating | Cooling | Humidifying | d | Humidification: It is a process of increasing the specific humidity at constant dry bulb temp. |

Comments | Active | |

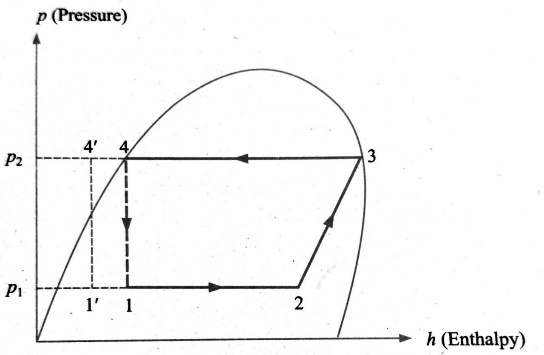

| 3 | Vertical lines on pressure-enthalpy chart shows: | Constant pressure lines | Constant temperature lines | Constant enthalpy lines | Constant entropy lines | c | A Pressure-Enthalpy (P–h) chart is widely used in refrigeration and thermodynamics to represent the state points of a refrigerant. Each axis and curve in this chart has specific thermodynamic significance. Vertical lines on pressure-enthalpy chart shows Constant enthalpy lines. | Comments | Active | |

| 4 | In which coal firing system coal is fed through compressed air? | Pulverized firing | Stoker firing | Both (a) & (b) | None of these | a | In a pulverized coal firing system: Coal is finely crushed (pulverized) into powder form. This pulverized coal is blown into the furnace using a stream of compressed air (primary air). The air helps carry the coal particles and also supports combustion. This system is widely used in thermal power plants due to: Better combustion efficiency Quick response to load changes Uniform heat distribution |

Comments | Active | |

| 5 | Which of the following is a high pressure boiler? | Lancashire boiler | Benson boiler | Locomotive boiler | Cochran boiler | b | Benson Boiler is a supercritical water-tube boiler, operating at very high pressures (above critical pressure = 221.2 bar). | Comments | Active | |

| 6 | The isothermal efficiency of a compressor is defined as | Isothermal work / Actual work | Adiabatic work / Actual work | Actual work / Isothermal work | Actual work / Adiabatic work | a | \(Isothermal Efficiency=\frac{Isothermal work}{Actual work}\) | Comments | Active | |

| 7 | Which of the following is not a boiler mounting? | Blow off cock | Feed check valve | Economiser | Fusible plug | c | Boiler Accessories (Not essential but improve efficiency): Economiser Superheater Air Preheater Feed Pump |

Comments | Active | |

| 8 | Which of the following is a water tube boiler? | Lancashire boiler | Babcock & Wilcox boiler | Locomotive boiler | Cochran boiler | b | Babcock & Wilcox is a horizontal water tube boiler, widely used in thermal power plants and capable of generating high-pressure steam. | Comments | Active | |

| 9 | Which of the following is not true about steam engine? | These may be used in locomotive trains. | They run on coal. | They are a type of I.C. engine. | Piston cylinder arrangement is there in a steam engine. | c | Steam Engines are not the type of I.C. Engine. In fact they are external combustion engines. | Comments | Active | |

| 10 | Which one of the following is a boiler mounting? | Feed pump | Fusible plug | Superheater | Economiser | b | Boiler Mountings are essential safety and control devices mounted on the boiler for its safe and efficient operation.Boiler Accessories improve efficiency but are not essential for operation. Boiler Mountings (Essential): Fusible Plug Safety valve Pressure gauge Water level indicator Steam stop valve Blow-off cock |

Comments | Active | |

| 11 | Centrifugal compressor is a type of ______ compressor. | Reciprocating | rotary | Both | None of these | b | A dynamic compressor, but it falls under the rotary category because the impeller rotates to increase the velocity and pressure of the gas. The gas is accelerated by rotating impeller and then decelerated in diffuser to convert velocity into pressure. |

Comments | Active | |

| 12 | COP of air refrigerator is related with COP of vapour compression refrigerator as | (COP)air > (COP)vap . | (COP)air<(COP)vap . | (COP)air = (COP)vap . | None of these | b | (COP)air<(COP)vap . COP (Air) ≈ 1 to 2 COP (Vapour Compression) ≈ 3 to 5 (can go higher depending on system) |

Comments | Active | |

| 13 | When discharge pressure is too high in refrigeration system, why is high pressure control installed? | To stop the cooling fan | To stop water circulating pump | To regulate the flow of cooling water | To stop the compressor | d | In a refrigeration system, high pressure control is a safety device used to: Monitor the discharge pressure of the compressor Protect the system from damage due to excessively high pressure (which can occur due to poor heat rejection, blocked condenser, fan failure, etc.) What happens if pressure goes too high? Compressor components can overheat or burst Risk of system failure or refrigerant leakage Hence, the compressor must be stopped immediately to prevent damage |

Comments | Active | |

| 14 | In vapour compression refrigeration system, the sub-cooling of refrigerants in the condenser results in: | Decrease in COP of the system | Decrease in the size of the condenser | Increase in the size of the evaporator | Increase in the size of the compressor | c |  It increase refrigerating effect and C.O.P Increase in the size of the evaporator |

Comments | Active | |

| 15 | The normal boiling point of refrigerant R-11 in comparison to refrigerant R-12 is: | Higher | Lower | Equal | None of these | a | R-11 has a much higher boiling point than R-12. Refrigerant Chemical Name Boiling Point (°C) R-11 Trichlorofluoromethane (CCl₃F) +23.7°C R-12 Dichlorodifluoromethane (CCl₂F₂) –29.8°C |

Comments | Active | |

| 16 | Pick up the correct statement about giving up of heat from one medium to other in ammonia absorption refrigeration system. | Strong solution to weak solution | Ammonia vapour to weak solution | Weak solution to strong solution | Ammonia vapour to strong solution | c |  |

Comments | Active | |

| 17 | The higher temperature in vapour compression refrigeration cycle occurs at: | Evaporator | Condenser discharge | Compressor discharge | Expansion valve | c | When refrigerant leaves the compressor, it becomes superheated vapor at high pressure and high temperature. This is the highest temperature point in the cycle. |

Comments | Active | |

| 18 | The relative Coefficient of Performance (COP) is: | Actual COP/theoretical COP | Theoretical COP/actual COP | Actual COP × theoretical COP | \(1-(\frac{actual COP}{theoretical COP})\) | a | The Coefficient of Performance (COP) is a measure of efficiency for refrigeration and heat pump systems. COP = Actual COP/theoretical COP | Comments | Active | |

| 19 | In a psychrometric process, if the sensible heat added is 30 kJ/s and latent heat added is 20 kJ/s, then the sensible heat factor will be: | 0.3 | 0.6 | 0.67 | 1.5 | b | \(Sensible heat factor=\frac{sensible heat}{Total heat}=\frac{S.H.}{L.H.+S.H.}=\frac{30}{30+20}=0.6\) | Comments | Active | |

| 20 | If air is passed over the cooling coils, this process is termed as: | Sensible heating | Cooling with humidification | Cooling with dehumidification | None of these | c | Cooling and dehumidification: This process involves lowering of both the air temperature and the specific humidity. This process is commonly used in summer air conditioning in which air passes over a cooling coil. When moist air is cooled below its dew point, vapour is condensed from the air resulting in simultaneous cooling and dehumidification. | Comments | Active | |

| 21 | If air is heated without changing its moisture content, the dew point will________. | Increase | Decrease | Remain the same | Be unpredictable | c |  |

Comments | Active | |

| 22 | In an ideal vapour absorption system, the absorber pressure is equal to the pressure of | Generator | Condenser | Evaporator | Expansion device | c |  |

Comments | Active | |

| 23 | Which of the following refrigeration plant requires no electricity? | Vapour absorption | Vapour compression | Air refrigeration | None of these | a | Works on a thermal energy source (e.g., solar, LPG, steam, or waste heat) Common refrigerant-absorbent pair: Ammonia–Water or Water–LiBr No compressor is used — replaced by absorber, generator, pump, and regenerator |

Comments | Active | |

| 24 | In a refrigerator, the flow of refrigerant is controlled by: | Compressor | Condenser | Evaporator | Expansion valve | d Component Function Compressor Compresses vapour, raises pressure & temperature Condenser Rejects heat, condenses refrigerant to liquid Expansion Valve Controls refrigerant flow & pressure drop Evaporator Absorbs heat from |

Comments | Active | ||

| 25 | One Ton refrigeration is equal to: | 50 kcal/min | 50 kcal/hr | 80 kcal/min | 1000 kcal/day | a | One Ton of Refrigeration (1 TR) is defined as the rate of heat removal required to freeze 1 ton (1000 kg) of water at 0°C into ice at 0°C in 24 hours. 1 TR = 210 kJ/min 1 kcal = 4.187 kJ 1 TR=210/4.187= 50.17 kcal/min |

Comments | Active | |

| 26 | Chemical formula for R22 refrigerant is | Mono chloro di fluoro methane | Tri chloro mono fluoro methane | Di chloro mono fluoro methane | Di chloro di fluoro methane | a | R-22 is a hydrochlorofluorocarbon (HCFC) refrigerant, commonly used in air conditioners and refrigeration systems before phase-out began due to its ozone depletion potential. it's called monochloro difluoro methane. | Comments | Active | |

| 27 | Which of the following is undesirable property of refrigerant? | Low viscosity | Low freezing point | Low latent heat of vaporization | Satisfactorily miscible with lubricating oil. | c | When selecting a good refrigerant, desirable properties include: High latent heat of vaporization → to absorb more heat per kg Low boiling and freezing points → to allow efficient cooling at low temperatures Low viscosity → for better flow through pipes Non-toxic, non-flammable, chemically stable, and compatible with oil |

Comments | Active | |

| 28 | In vapour compression refrigeration system, at entrance to which component, the working fluid is super-heated vapour? | Evaporator | Condenser | Compressor | Expansion valve | b |  |

Comments | Active | |

| 29 | The working fluid used for absorption refrigerators working on heat from solar collectors is a mixture of water and | Carbon dioxide | Sulphur dioxide | Lithium Bromide | Freon – 12 | c | In absorption refrigeration systems (especially solar-powered), the most commonly used working fluid pair is: Water as the refrigerant Lithium Bromide (LiBr) as the absorbent |

Comments | Active | |

| 30 | The humidifying efficiency is given by: (Where B= Bypass factor during sensible cooling) |

1-B | B-1 | \(\frac{1}{B}\) | \(\frac{1}{1-B}\) | a | In Air Conditioning Systems, humidifying efficiency (or effectiveness) during sensible cooling or heating is defined as the fraction of air that actually comes in contact with the coil and gets conditioned. Bypass Factor (B) represents the fraction of air that bypasses the coil without getting conditioned. η=1-BPF |

Comments | Active | |

| 31 | The most suitable refrigerant for commercial ice plant is: | Brine. | Ammonia | Freon | Air | b | Ammonia (NH₃) has: High latent heat and COP (coefficient of performance) Excellent thermodynamic efficiency Low cost and natural refrigerant (zero ozone depletion potential) Ideal for large-scale applications like ice plants, cold storages, dairy, breweries |

Comments | Active | |

| 32 | The sensible heat factor is given by: (Where S=Sensible heat, L=Latent heat) |

\(\frac{S}{S+L}\) | \(\frac{L}{S+L}\) | \(\frac{S+L}{S}\) | \(\frac{S}{S-L}\) | a | \(Sensible heat factor=\frac{sensible heat}{Total heat}=\frac{S.H.}{L.H.+S.H.}\) | Comments | Active | |

| 33 | On psychrometric chart, wet bulb temperature lines are | Horizontal lines | Vertical lines | Straight inclined lines | None of these | c |  |

Comments | Active | |

| 34 | The loss of head at entrance in the pipe is equal to (Where v = velocity of liquid in the pipe) |

\(v^{2}/2g\) | 0.5 \(v^{2}/2g\) | 0.375 \(v^{2}/2g\) | 0.75 \(v^{2}/2g\) | b | Loss Coefficient (K) Loss Formula Remarks 0.5 h = K × v² / (2 × g) Sudden entry 0.5 h = K × v² / (2 × g) Sharp corner 1.0 h = v² / (2 × g) Kinetic energy fully lost 0.2 to 0.9 h = K × v² / (2 × g) Depends on radius of curvature 0.15 h = K × v² / (2 × g) Common in pipelines ~10.0 h = K × v² / (2 × g) Very high resistance |

Comments | Active | |

| 35 | The efficiency of a hydraulic press is given by: Where W=1 Weight lifted by Ram P = Force applied on plunger A = Area of Ram a = Area of plunger |

\(\frac{W}{P}×\frac{A}{a}\) | \( \frac{P}{W}×\frac{a}{A}\) | \(\frac{W}{P}×\frac{a}{A}\) | \( \frac{P}{W}×\frac{A}{a}\) | d | \(Efficiency=\frac{Output}{Input}=\frac{\frac{W}{A}}{\frac{P}{a}}=\frac{W}{P}×\frac{a}{A}\) | Comments | Active | |

| 36 | The critical depth for a channel is given by: Where q unit discharge through channel and g gravitational acceleration |

\((\frac{q}{g})^{\frac{1}{2}}\) | \( (\frac{q^{2}}{g})^{\frac{1}{3}}\) | \( (\frac{q^{3}}{g})^{\frac{1}{4}}\) | \( (\frac{q^{4}}{g})^{\frac{1}{5}}\) | b | For a rectangular open channel, the critical depth is the depth of flow at which the specific energy is minimum for a given discharge. \(y_{c}\) For rectangular channel: \(y_{c}=(\frac{q^{2}}{g})^{\frac{1}{3}}\) |

Comments | Active | |

| 37 | The boiling point of Ammonia is: | -100°C | -50°C | -33.3°C | 0°C | c | Refrigerant Chemical Name / Formula Boiling Point (°C) Remarks R-717 Ammonia (NH₃) –33.3°C Widely used in industry; toxic, no ozone depletion R-22 Chlorodifluoromethane –40.8°C Was common in A/C; phased out (ODP) R-134a Tetrafluoroethane –26.1°C Used in domestic fridges & cars R-12 Dichlorodifluoromethane –29.8°C Banned (high ODP) R-744 Carbon Dioxide (CO₂) –78.4°C (sublimation) Used in transcritical systems |

Comments | Active | |

| 38 | Vapour compression cycle is modification of: | Reversed Carnot cycle | Rankine cycle | Bell-Colman cycle | None of these | a | The vapour compression refrigeration cycle (used in refrigerators, air conditioners, etc.) is a practical and improved version of the Reversed Carnot cycle, designed to overcome the limitations of the ideal Carnot cycle. | Comments | Active | |

| 39 | The metacentric height of a ship is 0.1 m and the radius of gyration is 5 m. What would be the time of rolling of the ship? (Take g = 10 m/s²) | 10 sec \(π\) | 5 sec \(π\) | 20 sec \(π\) | 15 sec | a | \(T=2π.\frac{k^{2}}{g.GM}\) the values: \(T=2π.\frac{5^{2}}{10.0.1}=2π.\frac{25}{1}=2π.5=10π second\) |

Comments | Active | |

| 40 | For what value of depth of flow, the discharge over a broad crested weir is maximum? (Where H is the available head) |

H/3 | H/2 | H | 2 H/3 | d |  H = Head of water in the upstream side of the weir, L = Length of the weir. Applying Bernoulli equation at (1) and (2) \(0+0+H=0+ \frac{v^{2}}{2g}+h\) \(v= 2g(H-h)\) Discharge (Q) over weir; Area of flow x velocity \(Q= C_{d}\) \(Q=C_{d}×L×h×v\) \(Q=C_{d}×L×h2g(H-h)\) \(Q=C_{d}×L×h2g(Hh^{2}-h^{3})\) For maximum and minimum \(\frac{dQ}{dh}=0\) \(\frac{d}{dh}(Hh^{2}-h^{3})=0\) \(2Hh- 3h^{2}=0, 2H. 3h=0\) \(h=\frac{2}{3}H\) |

Comments | Active | |

| 41 | In case of fluid flow through pipes, cavitation is caused by: | Low pressure below a limit. | Weak material of pipe | High pressure | High velocity | a | Cavitation refers to the formation and collapse of vapor bubbles in a fluid flow when local pressure falls below the vapor pressure of the liquid. It usually occurs in regions of: High velocity → low pressure (Bernoulli's principle) |

Comments | Active | |

| 42 | The maximum hydraulic efficiency of an impulse turbine (Where \(θ=angle of blade tip at outlet)\) |

\((\frac{1+cosθ}{2})\) | \( (\frac{1-cosθ}{2})\) | \( (\frac{1+sinθ}{2})\) | \((\frac{1-sinθ}{2})\) | a | The hydraulic efficiency (n) of an impulse turbine like the Pelton wheel is: \(η_{h}=\frac{2V_{1}.u(1+cosθ)}{V12}\) For maximum efficiency, we optimize blade velocity leading to: \(υ= \frac{V_{1}}{2},\) \(η_{h(max) }=\frac{1+cosθ}{2}\) Where: = vane outlet angle (deflection angle) \(θ\) V₠= jet velocity u = bucket speed |

Comments | Active | |

| 43 | Stoke is the unit of | Kinematic viscosity in C.G.S. unit | Kinematic viscosity in M.K.S. unit | Dynamic viscosity in M.K.S. unit | Dynamic viscosity in S.I. unit | a | Kinematic viscosity (ν) = \(\frac{μ}{Ï}\) In C.G.S. system, the unit of kinematic viscosity is Stoke. 1 Stoke= \(1 cm^{2}/sec\) In SI units, the kinematic viscosity is expressed in m²/s |

Comments | Active | |

| 44 | In case of laminar flow, the loss of pressure head is proportional to | Velocity | (Velocity)2 | (Velocity)0.5 | (Velocity)1.5 | a | For laminar flow, the Hagen-Poiseuille equation governs the pressure head loss in a circular pipe: \(h_{f}= \frac{32μVL}{pgD^{2}}\) Where: \(h_{f}= head loss due to friction\) \(μ=dynamic viscosity\) \(V=mean velocity\) L = pipe length p = fluid density g = gravity D = diameter of pipe From this, it's clear that in laminar flow, head loss \(h_{f}âˆV\) |

Comments | Active | |

| 45 | Maximum discharge over a broad crested weir is given by: (Where the symbols have standard meanings) | Q = CdLH3/2 | Q = 0.5 CdLH5/2 | Q = 1.705CdLH3/2 | Q = 1.705CdLH5/2 | c | For a broad-crested weir, when the velocity head is neglected and free flow conditions prevail, the discharge is given by the standard formula: Q = 1.705CdLH3/2 | Comments | Active | |

| 46 | The channel flow is subcritical when Froude Number (Fr): | Fr < 1 | Fr = 1 | Fr > 1 | Fr = - 1 | a | Froude Number (Fr) Type of Flow Fr < 1 Subcritical (slow, deep flow) Fr = 1 Critical flow Fr > 1 Supercritical (fast, shallow flow) |

Comments | Active | |

| 47 | According to Chezy’s formula, the discharge through an open channel is: Where A = Area of flow C = Chezy‘s constant m = hydraulic mean depth i = uniform slope in bed |

\(Am×i\) | \( Cm×i\) | \( ACm×i\) | \( miA×C\) | c | Discharge Q= \(A×V, \) \(Velocity V=Cm×i, \) \(so discharge Q=ACm×i\) |

Comments | Active | |

| 48 | Which of the following equation is known as momentum principle? | \(F=\frac{d(m^{2}v)}{dt}\) | \( F=\frac{dv}{dt}\) | \( F=\frac{d(mv)}{dt^{2}}\) | \(F=\frac{d(mv)}{dt}\) | d | The Momentum Principle, also known as Newton's Second Law, in its general form (for variable or constant mass systems), is written as: \(F=\frac{d(mv)}{dt}\) F = Net external force m = Mass v = Velocity mv = Linear momentum |

Comments | Active | |

| 49 | If the flow is irrotational as well as steady, it is known as | Unsteady flow | Rotational flow | Non-uniform flow | Potential flow | d | Irrotational flow means the fluid particles are not rotating, and steady flow means the flow characteristics remain constant over time. Potential flow is a term used to describe a flow that is both irrotational and steady. | Comments | Active | |

| 50 | A piezometer tube is used for measuring | Temperature | Humidity | Pressure | None of these | c | A piezometer is a simple vertical tube connected to the side of a pipe or tank. It measures the static pressure head of a fluid. The height of the liquid column in the tube corresponds to the gauge pressure (pressure above atmospheric). It is suitable for liquids only (not for gases) and for moderate pressures. |

Comments | Active | |

| 51 | One poise is equal to | 0.1 N-s/m2 | 1 N-s/m2 | 10 N-s/m2 | 100 N-s/m2 | a | One poise is equal to 0.1 pascal-second (Pa·s) or 0.1 N-s/m2 Or 1 dyne-second per square centimeter (dyn·s/cm²) | Comments | Active | |

| 52 | Froude’s number is the ratio of Inertia force to | Pressure force | Elastic force | Gravity force | Surface tension force | c | Froude’s number= \(\frac{Inertia force}{Gravity force}\) | Comments | Active | |

| 53 | Impulse turbine is used for | Low head | High head | Medium head | High flow | b | Impulse turbines are typically used for high head applications. In an impulse turbine, the energy of the water is converted into kinetic energy via nozzles that direct a high-speed jet of water onto the turbine blades. | Comments | Active | |

| 54 | The unit of surface tension is: | N/m | N/m2 | N/m3 | N-m | a | Surface tension is a force per unit length that acts along the surface of a liquid, and it is responsible for phenomena like the formation of droplets or the ability of certain objects to float on a liquid surface despite being denser. The unit of surface tension is: Unit of surface tension=Force (N) / Length (m) N = Newton (unit of force) m = meter (unit of length) |

Comments | Active | |

| 55 | The relation between hydraulic efficiency (ⴄh), mechanical efficiency (ⴄm) and overall efficiency (ⴄ0) is: | ⴄh = ⴄ0 ⴄm \(×\) | ⴄm = ⴄ0 ⴄh \(×\) | ⴄ0 = ⴄh ⴄm \(×\) | None of these | c | Overall efficiency = hydraulic efficiency (ⴄh ) x mechanical efficiency (ⴄm) |

Comments | Active | |

| 56 | Multistage centrifugal pumps are used for: | High discharge | High head | Pump viscous fluids | All of these | b | Multistage pumps have multiple impellers, each adding energy to the fluid, enabling them to handle high heads efficiently. This is the primary reason for their use. | Comments | Active | |

| 57 | Which property of mercury is the main reason for use in barometers? | High density | Negligible capillary effect | Very low vapour pressure | Low compressibility | a | High density Primary reason in most standard explanations. Mercury’s high density (13.6 g/cm³) allows the barometer tube to be short — ~76 cm at 1 atm. If water were used instead, the tube would need to be ~10.3 m long, which is impractical. Therefore, this is the main practical reason mercury is used in barometers. However, UKPSC has given the option (c) correct. Although low vapour pressure is critical for accuracy, it is not the main reason mercury was chosen historically. Even if mercury had a higher vapour pressure, we could still manage it. But without high density, the barometer would be huge and unusable. |

Comments | Active | |

| 58 | The locating and clamping elements are generally made from | Epoxy concrete | Steel | Brass | Aluminium | b | Locating and clamping elements are key parts of jigs and fixtures that: Hold the workpiece securely in position Ensure precision and repeatability during machining Why Steel is Used: High strength – resists deformation under load Wear resistance – critical for repeated clamping/unclamping Toughness – handles impact and vibration during machining Can be hardened and ground for precision |

Comments | Active | |

| 59 | Lip angle of a single point tool is of the order of: | 10 - 20 \(°\) \(°\) | 30 - 45 \(°\) \(°\) | 50 - 60 \(°\) \(°\) | 60 - 80 \(°\) \(°\) | d | Standard range of lip angle:60° – 80° for most metal cutting operations | Comments | Active | |

| 60 | Lathe bed is usually made of | Structural steel | Stainless steel | Cast iron | Mild steel | c | The lathe bed is usually made of cast iron due to the following reasons: High damping capacity: Cast iron has excellent damping properties, which help in reducing vibrations during machining, providing a more stable operation. Strength and rigidity: Cast iron offers good strength and rigidity, which are essential for supporting the weight of the lathe machine and the workpiece during operation. Wear resistance: It is resistant to wear and tear, making it ideal for the high-load conditions in machining operations. |

Comments | Active | |

| 61 | The co-efficient of discharge of an orificemeter in comparison with a venturimeter is | Equal | Much smaller | Much more | None of these | b | Coefficient of discharge for venturimeter is 0.95 -0.97 Coefficient of discharge for orificemeter is 0.60 -0.65. |

Comments | Active | |

| 62 | The type of flow in which the velocity at any given time does not change with respect to space is called | Steady flow | Unsteady flow | Rotational flow | Compressible flow | (*) None of the options is correct. | The wording clearly matches the definition of “uniform flow.†But uniform flow is not given in the options, making it invalid or poorly framed. Among the given options, none satisfy the condition stated in the question. |

Comments | Active | |

| 63 | In terms of cutting tool material, CBN stands for: | Carbon Boron Nitride | Cubic Boron Nitride | Cubic Borox Nitrogen | Carbon Boron Nitrogen | b | CBN stands for Cubic Boron Nitride, which is a very hard material used in cutting tools, especially for high-speed machining of hardened materials like steels. CBN is the second hardest material after diamond and is known for its wear resistance, thermal stability, and ability to cut ferrous materials. | Comments | Active | |

| 64 | Which one of the following is not a type of grinding wheel failure mode? | Attritious wear | Erosive wear | Grain fracture | Bond fracture | b | Failure Mode Description Attritious wear The gradual dulling of abrasive grains due to rubbing rather than cutting. Common in grinding. Grain fracture Abrasive grains break down to expose new, sharp edges. Helps self-sharpening. Bond fracture The bonding material fails, and the grain gets dislodged from the wheel. Erosive wear This term is not typically associated with grinding wheels. It refers to material loss due to fluid or particle impact — more common in pipelines, turbines, etc., not in abrasive wear mechanisms of grinding wheels. |

Comments | Active | |

| 65 | Internal gears are made through | Hobbing | Shaping with pinion cutter | Shaping with rack cutter | Milling | b | Internal gears are manufactured by shaping process with a pinion cutter. Hobbing, milling and shaping with rack cutter is mainly used for external gears | Comments | Active | |

| 66 | Interchangeability can be achieved by | Standardisation | Better process planning | Simplification | Better product planning | a | Interchangeability refers to the ability to replace a part with another part of the same type without any custom fitting or adjustment. It is achieved primarily through standardization. Standardization involves establishing common dimensions, materials, and specifications for parts, making them interchangeable. | Comments | Active | |

| 67 | Which one of the following is not a type of maintenance of machine tool? | Corrective maintenance | Progressive maintenance | Preventive maintenance | Predictive maintenance | b | Type Description Corrective maintenance Performed after a fault occurs to restore functionality. Preventive maintenance Scheduled maintenance to prevent breakdowns, like oiling, inspection, etc. Predictive maintenance Uses data (sensors, condition monitoring) to predict failures before they happen. Progressive maintenance Not a standard term in maintenance categories. |

Comments | Active | |

| 68 | Which one of the following is not a mechanism for the conversion of rotatory into translator motion? | Slider-crank mechanism | Rack and pinion mechanism | Pitch mechanism | Screw and nut mechanism | c | Pitch mechanism is not an established mechanical system for motion conversion. The other three are valid mechanisms for converting rotary motion into translatory motion. |

Comments | Active | |

| 69 | To machine a hole or groove shape, which machine is used? | Slotting machine | Milling machine | Broaching machine | Cylindrical machine | c | A broaching machine is specifically used to machine internal and external shapes such as: Holes with complex profiles Keyways Splines Grooves Non-circular internal shapes It uses a broach tool with progressively larger cutting teeth to remove material in a single stroke, providing high accuracy and good surface finish. |

Comments | Active | |

| 70 | Which of the following is not a lathe fixture? | Four jaw chuck | Collet | Mandrels | Arbor | d | An arbor is not typically classified as a lathe fixture. It is used in milling machines, not lathes. Arbor holds cutters, like a saw blade or milling cutter, in a milling machine. | Comments | Active | |

| 71 | String milling machine is used for | Small work-pieces | Large work-pieces | Heavy and hollow work-pieces | All of these | a | String milling is a production milling technique used to machine a number of identical small workpieces at once. The workpieces are strung or mounted on a fixture (like a mandrel or rod) and passed under or along a rotating cutter. It is highly suitable for small components, like: Gears Washers Bushings Small rings, etc. |

Comments | Active | |

| 72 | Which standard taper is generally used in milling machine spindle? | Brown and sharp taper | Seller's taper | Chapman taper | Morse taper | d | The Morse taper is a standard self-holding taper commonly used in machine tool spindles, including: Drilling machines Milling machines Lathe tailstocks In milling machines, Morse tapers (usually MT3 or MT4) are often used in vertical spindle attachments, especially in manual and light-duty milling machines. However, UKPSC has given answer (a) which is incorrect because The Brown and Sharpe taper was historically used in older machines, including: Arbors Milling cutters Tool shanks in some milling machines, especially in the U.S. Since it is not as commonly used today in modern milling machines. So, option (d) is the correct answer. |

Comments | Active | |

| 73 | Which among the following, looks similar to planer type milling machine? | Universal housing planing machine | Single housing planing machine | Rotary table planing machine | Double housing planing machine | d | Planer Type Milling Machines: A planer type milling machine will look like a double column planer, but has milling heads mounted in various planes, vertical milling heads on the cross rail and horizontal heads at the sides (on columns). This enables it to machine a workpiece on several sides simultaneously. The planer type milling machines are primarily intended for producing long straight surfaces on large and heavy machine parts. | Comments | Active | |

| 74 | The cutting velocity is minimum for following machining operation: | Turning | Drilling | Grinding | Milling | b | Machining Operation Typical Cutting Speed (m/min) Notes Turning 30–300 Depends on tool material and workpiece Drilling 10–90 (HSS) / up to 150 (carbide) Low, but not the lowest Grinding 1000–3000 Highest, due to high surface speed of grinding wheel Milling 20–150 (HSS) / up to 300 (carbide) Moderate, but not the lowest However, UKPSC has given option d correct, which is incorrect as per above table. |

Comments | Active | |

| 75 | Which cutting tool is used in the planer machine? | Profile tool | Single point cutting tool | Double point cutting tool | Multipoint cutting tool | b | The tools used in planing and shaping are similar to single-point lathe tools, consisting of the shank and the point. Planing and shaping tools are made of H.S.S. or tipped with cemented carbides. | Comments | Active | |

| 76 | In shaper, feed on the work-piece is provided by moving | Vice | Quick return mechanism | Ram | Table | d | Feed Mechanism in shaper: table feed is intermittent and is accomplished on the return (non cutting) stroke when the tool has cleared the workpiece. The cross feed is given to the table with the help of a cross feed screw, which is actuated by a pawl which engages a notched wheel (ratchet) keyed to the screw. The spring loaded reversible pawl gets its motion from a slotted disc through a connecting rod and pawl arm or rocker arm. | Comments | Active | |

| 77 | Which one among the following cannot be a specification of lathe machine? | Size of chuck | Distance between centres | Length of bed | Swing over diameter | a | A lathe machine is commonly specified by standard parameters that define its capacity and working limits. These include: Specification Indicates Distance between centres Max length of workpiece the lathe can handle Length of bed Overall size of the lathe; related to the machine's rigidity and capacity Swing over diameter Max diameter of workpiece that can rotate over the bed without hitting it |

Comments | Active | |

| 78 | For machining operation of Elbow pipe, which combination is used as work holding device | Face plate with angle plate | Face plate with dog plate | Angle plate with dog plate | None of these | a | Elbow pipes are irregular-shaped components and cannot be held using standard chucks. They require custom fixturing for proper alignment and secure holding during machining (typically on a lathe or similar machine). The angle plate is bolted to the face plate, and the elbow is securely clamped to the angle plate. This setup ensures rigid and accurate positioning during machining. Components used: Component Purpose Face Plate Mounted on the lathe spindle; provides a flat base to mount fixtures Angle Plate Supports the irregular shape (like the elbow) at a required angle |

Comments | Active | |

| 79 | In a metal machining operation, surface roughness is expressed as | Feed²/4 nose radius \(×\) | Feed2/8 nose radius \(×\) | Feed2/12 nose radius \(×\) | Feed2/nose radius | b | The surface roughness (h) can be calculated from the following relation, \(h=\frac{f^{2}}{8R}\) where f - feed rate; R - nose radius The surface finish which is inverse of surface roughness can be improved by: \(∴\) decreasing feed rate increasing nose radius |

Comments | Active | |

| 80 | While performing thread cutting operation using a lathe machine, a single point thread cutting tool has | Any value of rake angle | Zero rake angle | Positive rake angle | Negative rake angle | b | Thread cutting is done by zero rack angle. | Comments | Active | |

| 81 | If L = length of cut, N = rpm, f = feed/rev, then machining time in boring operation is expressed as: | (fN)/L \(×\) | (fL)/N \(×\) | L/(Nf) \(×\) | \(\frac{N}{(F×L)}\) | c | Machining time T=, where: L = length of cut, N = rpm, f = feed/rev \(\frac{L}{f×N}\) | Comments | Active | |

| 82 | Draw cut type shaper cuts in | Forward stroke | Backward stroke | Both the strokes | None of these | b | The most widely used. “Pull or draw cut†shapers cut in the direction corresponding to the return stroke of an ordinary shaper and shaper in which the cutting takes place in the forward stroke is called the “Push cut Shaperâ€. | Comments | Active | |

| 83 | Which one of the following is not an advantage of timber reasoning? | Wood becomes hard. | Wood density decreases. | Wood density increases. | Wood becomes sensitive to fire | c | Wood loses water → mass reduces, volume remains nearly same → density decreases, not increases. | Comments | Active | |

| 84 | Core print is used in moulding for: | Supporting the core | Making hollow space in mould | Removing the core | Making core | a | In moulding for casting, a core print is a feature used to support the core within the mould. The core is placed inside the mould to create internal cavities or hollow sections in the casting. Core print is a part of the mould that provides the necessary support and alignment for the core, ensuring it stays in position during the casting process. |

Comments | Active | |

| 85 | The hardness of a grinding wheel is expressed by | Letter/Alphabet | Brinell hardness number | Diameter of indentor | Rockwell hardness number | a | Grade. The grade or hardness of a grinding wheel is a measure of the resistance offered by the combined strength of the bond and the abrasive grains to the external forces striving to tear the grains from the wheel. 1. Soft grade : A to H 2. Medium grade : I to P 3. Hard grade : Q to Z |

Comments | Active | |

| 86 | A drill bit with zero rake angle is known as | Flat drill | Straight fluted drill | Blind drill | Parallel shank twist drill | b | A straight fluted drill has flutes that are parallel to the drill axis, rather than helical (twisted). Because of this: There is no helix angle Hence, the rake angle is zero These drills are commonly used for non-metallic materials like brass or plastic, where a positive rake angle might cause the tool to dig in. |

Comments | Active | |

| 87 | The suitable cutting fluid for machining of alloy steel is | Kerosene | Water | Dry | Sulphurised mineral oil | d | Process Mg alloys Al alloys Cu Alloys Alloy Steels C Steel C-I Turning – SO SO SO SO SO Milling – SO SO SO SO SO Grinding / Drilling MO/SO SO MO/FO SO/MO SO/EP SO/EP Heavy turning MO/SO MO MO/FO MO EP EP Heavy Milling MO MO/FO MO EP EP Tapping, Broaching MO EP EP SO = Soluble Oil; MO = Mineral Oil; FO = Fatty Oil; EP = Extreme Pressure oil. Refrence : Production and Technology by P.C. Sharma, page no-821 |

Comments | Active | |

| 88 | What is the variation of cutting speed with tool life on log-log scale? | Parabolic | Straight line | Elliptical | Hyperbolic | b | The relationship between cutting speed (V) and tool life (T) is given by Taylor’s Tool Life Equation: \(VT^{n}=C\) Taking logarithm on both sides: \(n logT+logV=logC\) Or \(logV=logC-n logT\) (which is a straight-line equation) \(y=C-mx\) |

Comments | Active | |

| 89 | In a machine tool, cutting force and power involved can be measured by: | Comparator | Dynamometer | Transducer | Pyrometer | b | In a machine tool, the cutting force and power involved in a machining operation are typically measured using a dynamometer. Dynamometer is an instrument used to measure force, torque, or power during machining operations. |

Comments | Active | |

| 90 | Binding material used in cemented carbide cutting tool is | Graphite | Lead | Carbon | Cobalt | d | Cemented carbide cutting tools are made by combining carbide particles (such as tungsten carbide, WC) with a binding material that holds the particles together and provides the necessary toughness. The most commonly used binding material for cemented carbide tools is Cobalt (Co). Cobalt is used because it provides the required strength, toughness, and resistance to wear without compromising the hardness of the carbide particles. Graphite, lead, and carbon are not used as the binding material for cemented carbide tools. |

Comments | Active | |

| 91 | Which of the following jig is used for easily drilling a number of holes on a component from different angles? | Ring Jig Used for cylindrical parts like shafts – for drilling holes around their surface |

Box Jig | Plate Jig Flat jig placed on top of the component – used for simple hole patterns |

Leaf Jig Has a hinged leaf for loading/unloading – used for repetitive side holes |

b | A Box Jig is an enclosed-type jig that surrounds the workpiece on multiple sides. It allows: Firm clamping of the workpiece Accurate drilling from different angles using bushings placed on various faces Very useful for complex components that require multiple holes at different orientations. Jig Type Purpose/Limitations |

Comments | Active | |

| 92 | Several machine tools can be controlled by a central computer in case of: | DNC machine tool | CNC machine tool | NC machine tool | ACS machine tool | a | In the case of DNC (Direct Numerical Control) machine tools, several machine tools can be controlled by a central computer. DNC is a more advanced form of NC (Numerical Control), where the central computer can send commands to multiple machines, allowing for synchronized control of multiple machine tools simultaneously. DNC (Direct Numerical Control): Centralized control of multiple machines via a computer. CNC (Computer Numerical Control): Each machine tool is controlled by its own computer. NC (Numerical Control): Earlier system, where each machine tool has its own controller but not centralized. ACS (Automatic Control System): Generally refers to control systems but not specific to centralized machine control. |

Comments | Active | |

| 93 | The degrees of freedom of a rigid body in space is: | 3 | 6 | 12 | 18 | b | The degrees of freedom (DOF) of a rigid body in space refer to the number of independent motions it can undergo. A rigid body in three-dimensional space can move in the following ways: Translation: The body can move along the x, y, and z axes — this gives 3 translational degrees of freedom. Rotation: The body can rotate about the x, y, and z axes — this gives 3 rotational degrees of freedom. Degrees of Freedom=3 (translation)+3 (rotation)=6 |

Comments | Active | |

| 94 | For high tensile strength material the abrasive recommended for grinding is: | Al2O3 | SiO₂ | Ceramic sand | Sand stone | a | Aluminum Oxide (Al₂O₃) is the most commonly used abrasive for high tensile strength materials such as: Steel Alloy steels Carbon steels High-speed steels Reason: It has: High hardness Toughness Good wear resistance It is ideal for grinding ferrous metals, which have high tensile strength. |

Comments | Active | |

| 95 | Trepanning operation is for | A large hole without drilling | A finished drilled hole | Enlarged hole after drilling | None of these | a | Trepanning is a machining operation used to cut a large hole in a workpiece without drilling a pilot hole. It is typically performed with a trepanning tool that cuts a hole by removing the material in the form of a ring or a circular piece from the center of the workpiece. This operation is used when a large, central hole is needed quickly and efficiently. | Comments | Active | |

| 96 | Involute gear on a milling machine is cut by using | Spiral cutter | Slab milling cutter | Angle milling cutter | Differential indexing head | d | To cut involute gears on a milling machine, two essential things are required: Gear cutter (usually an involute profile form cutter or gear hob) Indexing mechanism to rotate the blank by the correct angle between teeth A differential indexing head is a special attachment that allows precise angular movement of the gear blank. It enables indexing the gear blank to accurately cut each tooth of the involute gear profile. Especially useful when non-standard numbers of teeth are needed (which cannot be done with plain indexing). |

Comments | Active | |

| 97 | High rate of material removal is in: | EDM | LBM | USM | ECM | d | Among the options provided, Electrochemical Machining (ECM) is known for having a high rate of material removal. This process uses electrochemical reactions to remove material, and the rate at which material is removed is high due to the combined effects of electrical energy and chemical processes. | Comments | Active | |

| 98 | For turning steep and short taper, which taper turning method is used? | Compound rest method Short & steep tapers with better accuracy |

Tail-stock set over method Long & slight tapers (small angles, gradual slope) |

Taper turning attachment Long & accurate tapers (steeper angles too) |

Forming tool method Steep and short tapers (quick, rough operation with less accuracy) |

a | Method Best suited for |

Comments | Active | |

| 99 | Which of the following is not the part of the carriage of a lathe? | Saddle | Cross-slide | Tool post | Tail-stock | d | The carriage of a lathe is the assembly that slides along the bed and holds the cutting tool in position. It typically consists of Saddle, Cross-slide and Tool post. | Comments | Active | |

| 100 | The taper in the lathe spindle is: | 1:10 | 1:12 | 1:15 | 1:20 | d | The lathe spindle taper (particularly the headstock spindle internal taper) is usually standardized for: Mounting centers, arbors, or live centers The most commonly used taper for this purpose is the Morse Taper (1:20) |

Comments | Active | |

| 101 | Lap joint employed on plate having thickness: | Less than 3 mm | 5 to 10 mm | 12.5 mm | Above 25 mm | a | A lap joint is a fillet weld joint where two plates overlap each other. This joint is best suited for thin sheets or plates, because: It is simple and easy to fabricate. It avoids excessive distortion that occurs with thicker plates. “Lap joints are generally used for plates having thickness less than or equal to 3 mm.†|

Comments | Active | |

| 102 | A mortise gauge is a | Striking tool | Planing tool | Boring tool | Marking tool | d | A mortise gauge is a precision marking tool used in woodworking and fitting to: Scribe two parallel lines simultaneously Help in laying out mortise and tenon joints |

Comments | Active | |

| 103 | Buffing process is employed. | To remove the material by CBN abrasive. | To remove the material by diamond abrasive. | To improve dimensional accuracy. | To get perfectly flat surface. | d | Buffing is a finishing process used to: Improve surface smoothness and shine Remove fine scratches Produce a mirror-like finish It uses soft cloth wheels (buffs) and fine abrasive compounds (not CBN or diamond). Material removal is minimal — it's not meant for dimensional accuracy but for surface finish. |

Comments | Active | |

| 104 | Gear finishing operation is called | Shaping | Milling | Hobbing | Burnishing | d | Shaping and Milling: Used for gear cutting, not finishing. Hobbing: A gear generation process, not a finishing process. Burnishing: This is a surface finishing process used to improve surface finish, dimensional accuracy, and remove burrs or small imperfections from gears after cutting. |

Comments | Active | |

| 105 | In thread cutting process, which tap is used in last? | Plug tap | Bottoming tap | Taper tap | None of these | b | In internal thread cutting (tapping), a set of three taps is often used in sequence: Tap Type Order of Use Purpose Taper Tap 1st (Starting tap) Begins the thread with gentle taper (6–10 threads) Plug Tap 2nd Cuts threads deeper (4–5 threads tapered) Bottoming Tap 3rd (Last) Cuts threads fully to the bottom of the hole (1–2 threads tapered) The bottoming tap is used last to complete the thread to the full depth, especially in blind holes. |

Comments | Active | |

| 106 | Spigot and Socket joint is a type of: | Pipe joint | Weld joint, | Soldering | Wood joint | a | A Spigot and Socket joint is commonly used in cast iron piping systems. In this joint: The spigot is the plain end of the pipe. The socket is the enlarged end of another pipe that receives the spigot. The joint is usually sealed using jute or hemp and molten lead or rubber rings to make it leak-proof. |

Comments | Active | |

| 107 | Forging temperature of brass is | 550°C to 900 °C | 100°C to 550°C | 550°C to 1200°C | 900°C to 1200°C | a | The melting point of brass varies according to its composition, but most of the brasses in the common range liquify between temperatures of 850°C and 960°C. Hard brass may be softened by heating to about 750°C. For hot forging, the metal is heated to a temperature below the melting point but above the recrystallization point. (Refrence by: Production and Technology by P.C. Sharma, page no. 55) |

Comments | Active | |

| 108 | Which of the following is not a drilling and boring tool? | Auger | Bradawl | Gimlet | Spoke | d | Auger- A drilling tool (especially in wood) with a helical shaft. Bradawl- A pointed hand tool used to make small holes in wood. Gimlet- A small tool for drilling holes, usually in wood, with a handle. Spoke - A spoke is not a tool, but a part of a wheel (bicycle, cart, etc.). |

Comments | Active | |

| 109 | For USM, liquid used should not have following property: | Good wetting characteristics | High thermal conductivity | Anti-corrosive property | High viscosity | d | In Ultrasonic Machining (USM), a liquid slurry (usually a mix of abrasive particles in a fluid) is used to assist in material removal. The liquid used should have: Good wetting characteristics: to ensure effective transmission of ultrasonic vibrations. Anti-corrosive properties: to protect both the tool and workpiece from chemical damage. Reasonable thermal conductivity: to help in dissipating heat. High viscosity hinders the flow of slurry between tool and workpiece. |

Comments | Active | |

| 110 | In AJM process nozzles are made of the following material | WC | Low carbon steel | SS | HSS | a | In Abrasive Jet Machining (AJM), the nozzle is subjected to high-velocity abrasive particles that cause severe wear. Therefore, nozzle material must have extremely high wear resistance. Tungsten Carbide (WC) is widely used because of its: High hardness Excellent wear resistance Ability to withstand erosion from high-speed abrasive particles |

Comments | Active | |

| 111 | Radial lines of wood cells are | Annual rings | Pith | Medullary rays | Cambium layer | c |  1. Pith: It is the inner most part of tree consist of cellular tissue which is used for nourishment of tree in young age. 2. Sapwood: It is outer annual rings between heartwood and cambium layers. It is the living, outermost portion of a woody stem or branch. 3. Heartwood: The inner annual rings surrounding the pith is known as heartwood. It imparts rigidity to the tree. 4. Cambium Layer: It is a thin layer of sap between sapwood and inner bark. 5. Inner bark: It gives protection of the cambium layer 6. Outer bark: It is the outermost part of the tree |

Comments | Active | |

| 112 | Which one is not related to the shop layout? | Accurate size of land | Area of shop | Cost of product | Number of machines | c | Shop layout refers to the arrangement of machines, equipment, and other facilities within a manufacturing shop to ensure smooth workflow and maximum efficiency. The goal is to optimize space utilization, material movement, and labor efficiency. | Comments | Active | |

| 113 | The material of the lapping tool is the work-piece material. | Harder than | Softer than | As hard as | Any material can be used | b | The lap must embed the abrasive particles on its surface so they can cut into the harder workpiece. If the lap were harder, it would resist embedding the abrasives, reducing the cutting action. A softer lap conforms slightly to the work surface and holds the abrasives better, ensuring uniform material removal. |

Comments | Active | |

| 114 | The thrust force in drilling does not depend on: | Strength of the work-piece material | Feed | Drill diameter | Type of drilling machine used | d | The machine type (e.g., bench drill, radial drill, CNC drill) affects things like: Ease of operation Accuracy Production rate But it does not change the physical force required to cut into the material. Thrust is a function of material, tool geometry, feed, and cutting conditions – not the machine type. |

Comments | Active | |

| 115 | The tendency for built-up edge formation in chips can be reduced by: | Decreasing the cutting speed | Increasing the depth of cut | Increasing the rake angle | Avoiding the use of cutting fluid | c | Built-up edge (BUE) is a phenomenon in metal cutting where material from the workpiece adheres to the cutting edge of the tool. This is undesirable as it affects surface finish and tool life. To reduce BUE formation: Increasing rake angle reduces pressure and friction at the tool-chip interface. Higher rake angle promotes smoother chip flow, reducing the sticking tendency. Higher cutting speed and use of cutting fluids also reduce BUE |

Comments | Active | |

| 116 | A universal chuck used on lathe machine has | Three jaws | Four jaws | Two jaws | Six jaws | a | A universal chuck, also known as a self-centering chuck, is commonly used on lathe machines for holding cylindrical workpieces. It is equipped with: Three jaws that move simultaneously when the chuck is adjusted. This ensures self-centering, meaning the workpiece remains concentric with the lathe axis. |

Comments | Active | |

| 117 | Which instrument is not used for the measurement of the thickness of the metal sheet? | Wire gauge | Screw gauge | Steel scale | Vernier callipers | b | Screw gauge is not generally used for measuring sheet metal thickness. It's ideal for wires and small cylindrical objects, not flat sheets. |

Comments | Active | |

| 118 | In Galvanized Iron Sheet (GI), zinc is used | To make it flexible | To make it corrosion resistant | To make it cheap | All of these | b | Galvanizing is the process of applying a protective layer of zinc to iron or steel to prevent rusting (corrosion). Zinc acts as a sacrificial anode – even if the coating is scratched, zinc will corrode before iron does, thus protecting the underlying metal. It does not make the material cheaper or more flexible. |

Comments | Active | |

| 119 | If the silica sand particles are rounded in the moulding sand, which of the following increases? | Strength | Porosity | Shrinkage allowance | All of these | b | When silica sand particles are rounded in moulding sand: Porosity increases because: Rounded grains have larger interstitial spaces (voids) compared to angular grains. This allows better permeability and gas escape, which is critical in moulds to avoid defects like blowholes. |

Comments | Active | |

| 120 | Which material is generally used for making swage block? | Mild steel | High strength steel | Pig iron | Cast iron | d | A swage block is a heavy, thick block used in forging and blacksmithing operations for shaping, heading, or forming metal. It contains various grooves, slots, and holes to support different shaping tasks. Cast iron is the preferred material due to: Excellent compressive strength Good machinability High wear resistance Ability to dampen vibrations effectively |

Comments | Active | |

| 121 | Which chemical is used for making acetylene in an acetylene generator? | CaCO3 | CaC2 | BaCO3 | BaO | b | In an acetylene generator, acetylene gas (C₂H₂) is produced by the reaction of calcium carbide (CaC₂) with water: CaC2+2H2O→C2H2+Ca (OH)2 Calcium carbide (CaC₂) is the standard industrial chemical used to produce acetylene gas. The gas is typically used for oxy-acetylene welding and cutting. |

Comments | Active | |

| 122 | In ultrasonic machining process, the tool material should have | Low toughness & low ductility | High toughness & low ductility | Low toughness & high ductility | High toughness & high ductility | d | In Ultrasonic Machining (USM): The tool oscillates at high frequency (~20 kHz) and transfers energy to abrasive particles. These abrasives erode the hard, brittle workpiece, but the tool itself should survive the impact cycles. Hence, the tool material must have: High Toughness → To resist crack formation from repeated stress. High Ductility → To allow deformation without fracture. |

Comments | Active | |

| 123 | Gullet angle of the teeth of rip saw is upto | 30° | 40° | 50° | 60° | a | The gullet angle (or rake angle) of a rip saw tooth is designed to cut along the grain of the wood. For rip saws, this angle is generally less aggressive compared to crosscut saws. The typical gullet angle for rip saw teeth is up to 30°. This helps in efficient chip removal without damaging the wood fibers along the grain. |

Comments | Active | |

| 124 | Self-lubricating bearing is produced by which process? | Machining | Die casting | Powder metallurgy | Investment casting | c | Self-lubricating bearings are typically manufactured using powder metallurgy. In this process, metal powders (often bronze or iron) are compressed and sintered, creating a porous structure. These pores are later impregnated with lubricating oil, which exudes during operation, providing automatic lubrication. |

Comments | Active | |

| 125 | In which casting process, the pattern is not removed before pouring the liquid metal? | Investment casting. | Lost foam casting | Ceramic mould casting | Shell casting | b | In Lost Foam Casting (LFC), the pattern is made of expanded polystyrene (EPS). This foam pattern is not removed before pouring; instead, it vaporizes when molten metal is poured into the mould cavity. This eliminates the need for pattern removal, ensuring high dimensional accuracy and less machining. |

Comments | Active | |

| 126 | What is the input material of a cupola furnace? | Cast Iron | Pig Iron, | Steel | Mild steel | b | cupola furnace is a vertical shaft furnace used primarily in foundries for melting ferrous metals. The main input charge material is Pig Iron, often along with scrap iron, limestone (as flux), and coke (as fuel). Pig iron provides the primary iron content, while coke serves as the heat source. |

Comments | Active | |

| 127 | In arc welding, the ratio of weight of metal actually deposited with the weight of metal of electrode consumed is known as | Electrode metal ratio | Consumption ratio | Consumption efficiency | Electrode efficiency | d | Electrode Efficiency is defined as: Electrode Efficiency= \(\frac{Weight of metal deposited}{Weight of electrode consumed}×100\) It tells us how effectively the electrode is utilized during the welding process. |

Comments | Active | |

| 128 | Penetration of weld is to power density. | Inversely proportional | Equal | Proportional | Has no relation | c | Weld penetration refers to how deep the heat source can melt into the base material. It is directly proportional to the power density of the welding process. Penetration ∠Power Density Power Density = \(\frac{power of heat source in W}{Area in mm^{2}}\) High power density (e.g., Electron Beam Welding, Laser Beam Welding) results in deep and narrow penetration. Low power density (e.g., Oxy-acetylene welding) results in shallow and wide penetration. |

Comments | Active | |

| 129 | In shell moulding, the pattern is made up of which material? | Metal | Wood | Plastic | Any of these. | a | In shell moulding, a metal pattern is used, typically made from cast iron, steel, or aluminium. Reason: The process involves heating the pattern to 250–350°C. When thermosetting resin-coated sand is applied, it sticks to the hot metal pattern, forming a shell. Wood or plastic would deform or degrade at these temperatures. |

Comments | Active | |

| 130 | If metal is poured at a low temperature in mould, which type of defect may occur? | Misrun | Pinhole | Drop | Blow hole | a | A misrun occurs when the molten metal solidifies before completely filling the mould cavity, resulting in an incomplete casting. Causes of misrun: Low pouring temperature Slow pouring speed Poor fluidity of metal |

Comments | Active | |

| 131 | Among the following, the welding of which material is most difficult? | Mild steel | Low carbon steel | Cast Iron | All are equally difficult | c | Cast Iron is the most difficult to weld among the given options due to: High carbon content (2%–4%), which leads to: Formation of hard and brittle phases (like cementite or white iron). Tendency to crack during and after welding due to thermal stresses. Poor ductility and low weldability. Preheating and controlled cooling are essential to minimize cracking. Special electrodes or filler rods are needed (e.g., nickel-based). |

Comments | Active | |

| 132 | In SMAW/MMAW process if the electrode is not removed after touching quickly then | The welding transformer gets burnt | Electrode sticks to the work-piece | Arc is initiated easily | The welder's hand may get burnt | b | In SMAW/MMAW, the arc is started by briefly touching the electrode to the workpiece and then quickly withdrawing it. If not withdrawn quickly, there is no arc formation, a short circuit occurs and Electrode sticks to the work-piece |

Comments | Active | |

| 133 | Which chemicals are used during thermit welding? | Fe+Al2O3 | FeO + Al | FeO + Al2O3 | Fe + Al | c | Thermit welding: Heat is produced for welding by chemical reaction. Chemical reaction is as follow for iron oxide and Al: 3Fe3O4 + 8Al = 9Fe + 4Al2O3 + 3010 KJ/mole (3090°C), produced temperature should not be less than 2100°C as Al solidifies at 2040°C. It is fusion welding process. Thermit mixture is a mixture of (Al +Fe3O4) = 1:3, by mass Al 24% and Metal oxide powder 76%. |

Comments | Active | |

| 134 | In explosive welding which plate is kept at an angle to the horizontal? | Target plate | Flyer plate | Base plate | Both (a) & (b) | b | Inclination angle between flyer and target plate (included angle) = 3 to 15 degree (1 to 25 degree) flyer plate thickness = 0.25 mm to 30 mm |

Comments | Active | |

| 135 | In which welding process, the work-piece is kept in vacuum? | Laser Beam Welding | Electron Beam Welding | Plasma Are Welding | All of these. | b | Electron Beam Welding (EBW) is a high-energy welding process where: A focused beam of high-velocity electrons strikes the workpiece. It must be done in a vacuum to prevent electrons from scattering due to air molecules. This allows deep penetration, narrow welds, and minimal distortion. |

Comments | Active | |

| 136 | The water content in green sand for moulding is | 0-1% | 1-4% | 11-13% | 6-8% | d | Green sand is a moist mixture of: Silica sand Clay (typically bentonite) Water (6-8%) Sometimes additives like coal dust or wood flour |

Comments | Active | |

| 137 | Which of the following is not a refractory material? | Zirconia (ZrO2) | Alumina (Al2O3) | Titanium carbide (TiC) | Iron oxide (FeO) | d | FeO is not stable at high temperatures, and its oxidizing/reducing behavior makes it unsuitable for use as a refractory material. | Comments | Active | |

| 138 | The speed at which electrode moves or deposition takes place is known as | Electrode speed | Operation speed | Machine speed | Welding speed | d | In welding operations, particularly in arc welding, the term welding speed refers to: The rate at which the electrode or torch travels along the joint. Usually measured in mm/min or inches/min. It directly affects weld bead shape, penetration, and heat input. |

Comments | Active | |

| 139 | In Tungsten Inert Gas Welding (TIG) which of the gas can be used? | Acetylene (C₂H₂) | Oxygen (O2) | Helium (He) | All of these | c | TIG Welding (also known as GTAW – Gas Tungsten Arc Welding) uses: A non-consumable tungsten electrode Inert shielding gas to protect the weld zone from atmospheric contamination Common shielding gases in TIG welding: Argon (Ar) Helium (He) Mixtures of Argon and Helium These gases are chemically inert, meaning they do not react with molten metal. |

Comments | Active | |

| 140 | In resistance welding, the current in comparison to Arc welding is: | Less | More. | Equal | Current does not flow in resistance welding | b | Arc Welding- Welding Power Source -Electric discharge – Arc (charge flows from electrode to base metal), Ionised air gap is known as plasma or ARC requirement of welding Low Voltage and high current (20 to 80 V) \(→ \) RESISTANCE WELDING: Low voltage :(0.5 to 10V ); High Current (up to 1,00,000 amp) for the thickness of 3mm-10,000 ampere current is supplied) |

Comments | Active | |

| 141 | Which of the following is not true about centrifugal casting? | It produces hollow products. | Core is used. | Mould is used. | The mould is rotating. | b | Centrifugal casting is a process in which molten metal is poured into a rotating mold, and centrifugal force distributes the metal along the mold walls. Centrifugal force pushes the molten metal to the periphery, creating a hollow cylindrical product (like pipes or liners). Core is not used in centrifugal casting because the hollow shape is automatically formed due to centrifugal force. | Comments | Active | |

| 142 | In powder metallurgy, the desirable compression ratio for making product from metallic powder is: | 3:1 | 5:1 | 7:1 | 9:1 | c | In powder metallurgy, the compression ratio is defined as: Compression Ratio=Volume of loose powder/Volume after compaction A higher compression ratio helps achieve: Better green strength of the compact, Improved density, Dimensional accuracy after sintering. For most metal powders, especially iron and copper-based powders, a compression ratio of around 6:1 to 8:1 is considered desirable to ensure sufficient compaction and strength. |

Comments | Active | |

| 143 | In press working operation, if the sheet metal punched out portion is the required product, then the name of operation is | Piercing | Lancing | Shaving | Blanking | d | Blanking: The punched-out piece (blank) is the desired final product. The remaining sheet is scrap. Piercing: The hole is the desired result; the removed material is waste. Lancing: A partial cutting operation where the metal is cut and bent, but not completely separated. Shaving: A finishing operation to improve the edge quality of the previously blanked or pierced part. |

Comments | Active | |

| 144 | Which one of the following options describes the disadvantage of the cold forging process? | Enhanced surface finish | Residual stresses are generated | Elimination of wasted material | Improvement in mechanical properties | b | Cold forging involves plastic deformation of metal at room temperature. Although it offers several advantages such as: Excellent surface finish, Better dimensional accuracy, Material saving (no flash or trimming), Improved mechanical properties due to strain hardening, It also introduces residual stresses due to severe plastic deformation without thermal relaxation, which can: Affect dimensional stability, Lead to crack initiation under service conditions, Require additional stress relief processes. |

Comments | Active | |

| 145 | In a rolling process, the roll separating force can be reduced by | Increasing friction between roll & work-piece. | Providing the back-up roll | Decreasing the roll diameter | Increasing the roll diameter | c | The roll separating force is the force that tends to push the rolls apart during rolling. This force depends on several factors including roll diameter, friction, and material properties. Smaller roll diameter reduces the contact length between the roll and the workpiece. Shorter contact length leads to lower force required for deformation. Hence, reduces roll separating force. |

Comments | Active | |

| 146 | Part produced by powder metallurgy is often termed as part. | Cast | Sintered | Machined | None of these | b | In Powder Metallurgy, metal powders are first compacted into a desired shape and then heated (sintered) below the melting point to bond the particles. The final product is called a sintered part, as the sintering process imparts strength and shape retention. Term Description Sintering Heating compacted powder to bond particles Sintered part Final product after sintering Casting Involves molten metal – not used in powder metallurgy Machining May follow sintering but not the default outcome |

Comments | Active | |

| 147 | Match plate pattern is used in moulding. | Floor | Machine | Three-box | Plate | b | Match plate pattern is widely used in machine moulding due to its: High dimensional accuracy, Good repeatability, Faster production rate. It consists of split patterns mounted on opposite sides of a single match plate, which helps align cope and drag halves precisely on the molding machine. |

Comments | Active | |

| 148 | To completely burn one mole of Acetylene, how many moles of oxygen are required? | 1.0 | 1.2 | 0.8 | 2.5 | d | To find the required oxygen, we use the balanced chemical equation for the combustion of acetylene: \(C_{2}H_{2}+ \frac{5}{2}O_{2}→2CO_{2}+H_{2}O\) This shows that: 1 mole of C₂H₂ needs 2.5 moles of (i.e., moles) for complete combustion \(O_{2}\) \(\frac{5 }{2}\) |

Comments | Active | |

| 149 | The ability of sand to take up the desired shape is known as | Adhesiveness | Cohesiveness | Binding | Flowability | d | Flowability (or flowability of moulding sand) is the ability of sand to flow and fill the mould cavity properly, thus taking the desired shape of the pattern. It is essential for accurate replication of intricate details in casting. Property Definition Adhesiveness Ability to stick to another surface, e.g., mould walls. Cohesiveness Ability to stick to itself, providing strength to the sand. Binding Refers to bonding properties of the binder in the moulding sand. |

Comments | Active | |

| 150 | Convert pressure head of 10 m of water in terms of liquid with specific gravity of 0.8. | 8.5 m | 10.5 m | 11.5 m | 12.5 m, | d | We know that pressure head is related to specific gravity as: \(h_{1}.S_{1}= h_{2}.S_{2}\) Where: \(h_{1}=10m(head of water)\) \(S_{1}=1(specific gravity of water)\) \(S_{2}=0.8 (specific gravity of other liquid)\) \(h_{2}=required head in other liquid\) Apply the formula: \(10.1=h_{2}.0.8\) \(h_{2}=\frac{10}{0.8}=12.5m\) |

Comments | Active | |

| 151 | The work input of a compressor is minimum when the law followed by compression is: | Isentropic: = C \(PV^{γ}\) | Isothermal: = C \(PV\) | = C \(PV^{1.35}\) | = C \(PV^{1.25}\) | b | In gas compression, the work done is minimum when the compression process is isothermal, i.e., temperature remains constant during compression. | Comments | Active | |

| 152 | Phenomenon of choking in compressor means | No flow of air. | Fixed mass flow rate regardless of pressure ratio. | Reducing mass flow rate with increase in pressure ratio. | Increased inclination of chord with air stream. | b | In a compressor, particularly in axial flow or centrifugal compressors, choking occurs when the flow reaches sonic velocity (Mach 1) at the narrowest cross-section (usually the throat). At this condition, the mass flow rate cannot be increased further by lowering the downstream pressure — it becomes maximum and fixed. |

Comments | Active | |

| 153 | In Jet condensers: | Cooling water passes through tubes and steam surrounds them. | Steam passes through tubes and cooling water surrounds them. | Steam and cooling water mix. | Steam and cooling water do not mix. | c | In a Jet Condenser, exhaust steam directly mixes with the cooling water. This is unlike surface condensers, where steam and cooling water are separated by tubes. Feature Description Working Principle Direct contact between steam and water Type of Condensation Mixing type Condensate Composition Contains cooling water + condensate Advantage Simple design, low cost Disadvantage Cannot recover pure condensate |

Comments | Active | |

| 154 | Equivalent evaporation may be defined as the amount of water evaporated from water at 100 °C to: | Wet and dry steam at 100 °C | Wet and saturated steam at 100 °C | Dry and saturated steam at 150 °C | Dry and saturated steam at 100 °C | d | Equivalent evaporation is a standardized way of comparing boiler performance. It is defined as the amount of water evaporated from feedwater at 100 °C to dry saturated steam at 100 °C (at atmospheric pressure). This allows engineers to compare boilers operating under different pressures and feedwater conditions on a common basis. Equivalent Evaporation (kg) = \(\frac{Actual heat added to steam}{2257 kJ/kg}\) Where 2257 kJ/kg is the latent heat of vaporization of steam at 100 °C. |

Comments | Active | |

| 155 | Formation of steam bubbles on the surface of boiler water is due to: | Low surface temperature of the water | High surface temperature of the water | High surface tension of the water | Low surface tension of the water | b | Steam bubbles in boiler water form due to nucleate boiling, which occurs when the surface temperature exceeds the saturation temperature of the surrounding water. At this higher local temperature, water changes to steam at the heated surface, forming bubbles. |

Comments | Active | |

| 156 | In a surface condenser used in a steam power station, undercooling of condensate is undesirable as this would: | Not absorb the gases in steam | Reduce efficiency of the plant | Increase the cooling water requirements | Increase thermal stresses in the condenser | b | In a surface condenser, the objective is to condense exhaust steam from the turbine just at its saturation temperature, minimizing energy loss. If the condensate is undercool (i.e., cooled below its saturation temperature): No extra condensation takes place. But additional heat is removed, which does not contribute to any useful work. This increases irreversibility and hence reduces the thermal efficiency of the cycle. |

Comments | Active | |

| 157 | A single stage impulse turbine with diameter of 120 cm runs at 3000 rpm. If the blade speed ratio is 0.42, the inlet velocity of steam will be: | 200 m/s | 450 m/s | 900 m/s | 80 m/s | b | \(U=\frac{πDN}{60}= \frac{π×120×10^{-2}×3000}{60}\) \(=188.49 \frac{m}{s}\) Blade speed ratio = 0.42 Inlet velocity will be = 188.49/0.42 = 448.78m / s |

Comments | Active | |

| 158 | The ratio of work done to the energy supplied to rotor in a turbine stage is called | Blade efficiency | Stage efficiency | Nozzle efficiency | None of these | a | lade Efficiency (also called diagram efficiency) is defined as: \(η=\frac{work done on the blade}{kinetic energy supplied to the rotor}\) It refers specifically to how effectively the moving blades convert kinetic energy of steam (coming from nozzle) into mechanical work. |

Comments | Active | |

| 159 | Throttle governing in steam turbines: | Leads to significant pressure loss | Increases the efficiency | Increases heat loss | Decreases steam temperature. | a | Throttle governing is a method of controlling the power output of steam turbines by restricting the steam flow using a throttle valve placed before the turbine inlet. | Comments | Active | |

| 160 | If vb = blade speed v= Absolute velocity of steam entering the blade = nozzle angle \(α\) The efficiency of an impulse turbine is maximum when: |

vb=0.5 v cos \( α\) | vb= v cos \( α\) | vb= 0.5 v2 cos \( α\) | vb= v2 cos \( α\) | a | For an impulse turbine, the maximum blade efficiency is obtained when: \(v_{b}=\frac{v cosα}{2}\) This is derived from the condition for maximum efficiency of a single-stage impulse turbine using velocity diagrams. |

Comments | Active | |

| 161 | Critical pressure for steam is: | 184 bar | 163 bar | 221 bar | 252 bar | c | The critical pressure of steam is the pressure above which water and steam cannot exist as distinct phases. For pure water, the critical point occurs at: Critical Temperature: 374.15°C Critical Pressure: 221.2 bar (approximately) After this point, there is no latent heat of vaporization, and the substance transitions directly into a supercritical state. |

Comments | Active | |

| 162 | An engine produces 10 kW brake power, while working with a brake thermal efficiency c 30%. If the calorific value of the fuel used is 40,000 kJ/kg, then what is the fuel consumption? | 1.5 kg/hr | 3.0 kg/hr | 0.3 kg/hr | 1.0 kg/hr | b | \(η_{bth= }\frac{Break power}{m_{f }×CV} ⇒ m_{f}=\frac{BP}{η_{bth }×CV}\) \(where\) \(BP=10kW\) \(η_{bth}=0.30\) \(CV=40,000 \frac{kJ}{kg}\) Step-by-step Calculation: \(m_{f}= \frac{10}{0.30×40000}=\frac{10}{12000}=0.000833\frac{kg}{sec}\) Now convert to kg/hr: \(m_{f}= 0.000833 ×3600= 3.0 \frac{kg}{hr}\) |

Comments | Active | |

| 163 | Which one of the following types of swirls is generated by a pre-combustion chamber in the diesel engine? | Squish | Compression swirl | Induction swirl | Combustion induced swirl | d | In a pre-combustion chamber diesel engine, part of the fuel-air mixture is ignited in a small chamber and then rapidly forced into the main chamber. This high-pressure jet causes strong turbulence and swirling motion, known as combustion-induced swirl. Type of Swirl Generated By Induction Swirl During air intake through tangential ports Compression Swirl During compression stroke in cylinder Squish Radial motion due to piston movement Combustion Induced Swirl Due to high-speed jet from pre-combustion chamber |

Comments | Active | |

| 164 | The efficiency of an Otto cycle is 60% and gamma=1.5 determine the compression ratio. | 5.15 | 6.25 | 7.25 | 8.25 | b | \(η=1- \frac{1}{r^{γ-1}}\) Where: \(η=0.60(given)\) \(γ=1.5(given)\) compression ratio (to be found) \(r= \) \(0.60=1- \frac{1}{r^{1.5-1}}=1- \frac{1}{r^{0.5}}\) \(⇒ \frac{1}{r^{0.5}}=1-0.60=0.40\) \(r^{0.5}=\frac{1}{0.40}=2.5\) \(r= (2.5)^{2}= 6.25\) \(η=1- \frac{1}{r^{γ}-1}\) |

Comments | Active | |

| 165 | The part load and thermal efficiency of two stroke cycle engines as compared to four stroke cycle engines is: | Higher. | Equal | Unpredictable | Lower | d | Part load efficiency and thermal efficiency of two-stroke engines are lower compared to four-stroke engines due to: Loss of fresh charge during scavenging Higher fuel consumption per power developed |

Comments | Active | |

| 166 | The order of values of thermal efficiency of Otto, Diesel and Dual Cycles, when they have equal compression ratios and heat rejections, is given by | \(ⴄ_{otto}>ⴄ_{diesel}>ⴄ_{dual}\) | \( ⴄ_{diesel}>ⴄ_{dual}>ⴄ_{otto}\) | \(ⴄ_{dual}>ⴄ_{diesel}>ⴄ_{otto}\) | \( ⴄ_{otto}>ⴄ_{dual}>ⴄ_{diesel}\) | d | The Otto cycle adds all the heat at constant volume → results in highest peak temperature → highest thermal efficiency. The Diesel cycle adds heat at constant pressure → more heat rejection → lower efficiency. The Dual cycle is a combination of both and has intermediate efficiency. \(ⴄ_{otto}>ⴄ_{dual}>ⴄ_{diesel}\) |

Comments | Active | |

| 167 | Morse test is conducted for | Single cylinder engine only | Single cylinder and multi cylinder engine both. | Multi cylinder engine only | None of these | c | The Morse Test is a practical method to determine the indicated power (IP) of each cylinder in a multi-cylinder internal combustion engine without needing indicator diagrams. The test involves running the engine at full load, and then cutting off one cylinder at a time, measuring the corresponding drop in brake power (BP). This drop helps calculate the indicated power for the disabled cylinder. |

Comments | Active | |

| 168 | In which type of turbine, the expansion of steam does not take place in the moving blade? | Impulse turbine | Reaction turbine | Mixed turbine | None of these | a | In an Impulse Turbine: The entire pressure drop (expansion of steam) takes place in the nozzles. The moving blades simply convert the kinetic energy of the steam into mechanical work, without any further expansion. In a Reaction Turbine: The steam expands partially in the fixed blades and partially in the moving blades. Thus, expansion occurs in both. |

Comments | Active | |

| 169 | The ratio in turbine is called \(\frac{Heat convertd into useful work}{Total adiabatic heat drop}\) | Rankine efficiency | Blade efficiency | Overall efficiency | Internal efficiency | d | In steam or gas turbines, internal efficiency (also called isentropic efficiency of the turbine) is defined as: Internal Efficiency=Actual work output / Isentropic (adiabatic) heat drop It measures how efficiently the turbine converts the available heat energy (adiabatic heat drop) into useful mechanical work, accounting only for internal losses (like friction and turbulence within the turbine). |