| S.No | Question | Option A | Option B | Option C | Option D | Answer | Solution | Comments | Status | Action |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | In a Francis turbine runner, the number of blades are generally between | 2 to 4 | 4 to 8 | 8 to 16 | 16 to 24 | d | The Francis turbine is a type of water turbine. It is an inward-flow reaction turbine that combines radial and axial flow concepts. It has 16 to 24 blades. | Comments | Active | |

| 2 | In a centrifugal pump, the regulating valve is provided on the | Casing | Delivery pipe | Suction pipe | Impeller | b | A delivery valve is a regulating valve which is of sluice type and is required to be provided in order to control the flow from the pump into delivery pipe. | Comments | Active | |

| 3 | Reciprocating air compressor is best suited for | Large quantity of air at high pressure | Small quantity of air at high pressure | Small quantity of air at low pressure | Large quantity of air low pressure | b | Reciprocating Air Compressor is a positive displacement air compressor in which air is sucked in a chamber and compressed with the help of a reciprocating piston. It is called as positive displacement compressor because air is first sucked in a chamber and then compression is achieved by decreasing area of the chamber. | Comments | Active | |

| 4 | A weir is said to be narrow crested, if its crest width is less than | Height of water | Half the height of water | Length of the weir | Half the length of weir | b | Narrow Crested Weir: It is similar to rectangular weir with narrow shaped crest at the top. The discharge over narrow crested weir is similar to discharge over rectangular weir. | Comments | Active | |

| 5 | The discharge over a rectangular notch is expressed as – | \(\frac{2}{3}.C_{d}.b.2gH\) | \(\frac{2}{3}.C_{d}.b.2g×H\) | \(\frac{2}{3}.C_{d}.b.2g.H^{\frac{3}{2}}\) | \(\frac{2}{3}.C_{d}.b.2g.H^{\frac{5}{2}}\) | c | For rectangular notch Q = \(\frac{2}{3}.C_{d}.b.2g.H^{\frac{3}{2}}\) |

Comments | Active | |

| 6 | The discharge through a rectangular channel will be maximum, if its depth is | Twice the width | Same as its width | Half of the width | one third of the width | c | The discharge through a rectangular channel will be maximum, if its depth is half of the width. | Comments | Active | |

| 7 | A Pelton wheel is an | Axial flow impulse turbine | Inward flow impulse turbine | Outward flow impulse turbine | All of these | * | Pelton wheel is a tangential flow impulse turbine. | Comments | Active | |

| 8 | The power produced by a Reaction turbine is | Proportional to H | Inversely proportional to H | Proportional to \(H\) | Inversely proportional to \(H\) | a | \( P=ÏQgH\) | Comments | Active | |

| 9 | The specific speed (Ns) of a centrifugal pump is given by | \(NQ/H^{\frac{5}{4}}\) | \(NQ/H\) | \(NQ/H^{\frac{3}{4}}\) | \(NQ/H^{\frac{2}{3}}\) | c | Specific speed for pump: \(N_{S}=NQ/H^{\frac{3}{4}}\) |

Comments | Active | |

| 10 | The reciprocating pump has a slip of 3%. Its co-efficient of discharge ( is: \(c_{d})\) | 0.30 | 0.97 | 0.67 | 0.70 | b | Given \(Slip=0.03\) \(Slip=1-C_{d}\) \(C_{d}=1-0.03=0.97\) |

Comments | Active | |

| 11 | Which is more viscous lubricating oil? | SAE 30 | SAE 40 | SAE 50 | SAE 80 | d | SAE 80 is more viscous lubricating oil. | Comments | Active | |

| 12 | Pressure drag results from | Skin friction | Deformation drag | Development of a stagnation point | Formation of wake | d | Pressure drag comes from the eddying motions that are set up in the fluid by the passage of the body. This drag is associated with the formation of a wake in the flow. Frictional drag comes from friction between the fluid and the surfaces over which it is flowing. | Comments | Active | |

| 13 | The maximum efficiency of transmission through a pipe is | 50% | 60% | 62.5% | 66.7% | d | Condition for maximum efficiency \(h_{L}=\frac{H}{3}\) \(η=66.67%\) |

Comments | Active | |

| 14 | Stability of floating body depends upon: | Its volume | Its weight | Its metacentric height | The specific weight of fluid | c | Stability of floating body depends upon metacentric height. The metacentric height (GM) is a measurement of the initial static stability of a floating body. It is calculated as the distance between the centre of gravity of a ship and its metacentre. | Comments | Active | |

| 15 | A body is said to be floating when: | \(W>F_{b}\) | \(W=F_{b}\) | \(W| \(F_{b} |

b |

For a floating body, weight is balanced by the buoyant force. Hence, |

\(W=F_{B}\) Comments |

Active

|

|

|

| 16 | The Bernoulli’s theorem for liquid is applicable for: | Turbulent flow | Viscous flow | Compressible flow | None of the above | d | Assumptions of Bernoulli’s Equation i. The fluid is ideal, i.e., viscosity is zero ii. The flow is steady iii. The flow is incompressible iv. The flow is irrotational, non-turbulent and 1 dimension. |

Comments | Active | |

| 17 | The vanes of a centrifugal pump move due to | Pressure energy of water | Kinetic energy of water | Both pressure and kinetic energy of water | Power supplied by a prime mover | d | A centrifugal pump is a mechanical device designed to move a fluid by means of the transfer of rotational energy from one or more driven rotors, called impellers. Fluid enters the rapidly rotating impeller along its axis and is cast out by centrifugal force along its circumference through the impeller's vane tips. | Comments | Active | |

| 18 | The overall efficiency of Pelton wheel is about: | 55% | 65% | 85% | 99% | c | Overall efficiency of pelton wheel is about 85%. | Comments | Active | |

| 19 | Kaplan turbine is | An axial flow reaction turbine | An axial flow impulse turbine | An inward radial flow reaction turbine | An outward radial flow reaction turbine | a | Kaplan turbine is an axial flow reaction turbine. So the working fluid changes the pressure as it moves across the turbine and gives energy. | Comments | Active | |

| 20 | The difference between the theoretical discharge and actual discharge of a pump is known as | co-efficient of discharge | Slip | Percentage slide | None of the above | b | Slip of a reciprocating pump is defined as Difference of theoretical discharge and actual discharge. | Comments | Active | |

| 21 | A venturimeter is used to measure discharge through: | A pipe | An open channel | A weir | A notch | a | A venturi meter is a measuring or also considered as a meter device that is usually used to measure the flow of a fluid in the pipe. | Comments | Active | |

| 22 | A Carnot refrigeration cycle absorbs 1050 kJ/min at 250 K and rejects heat at 300 K. Work required per second in kJ is | 2.4 | 3.5 | 3.8 | 4.1 | b | Given = 17.5 kW \(Q_{2}=1050 kJ/min\) \(T_{2}=250 K\) \(T_{1}=300 K\) \(COP_{ref}=\frac{T_{2}}{T_{1}-T_{2}}=\frac{Q_{2}}{W}\) \(\frac{250}{300-250}=\frac{17.5}{W}\) \(W=3.5 kW\) |

Comments | Active | |

| 23 | The change in suction pressure in vapour compression refrigeration system | increases co-efficient of performance | Decreases work of compressor | Decrease refrigeration effect | Increases refrigeration effect | * | Since here change is not mentioned as increasing or decreasing, so it difficult to choose the right option among the given options. | Comments | Active | |

| 24 | The capacity of refrigerating machine is expressed as: | Inside volume of cabinet | Lowest temperature attained | Gross weight of machine in tons | Rate of abstraction of heat from space being cooled | d | Refrigeration capacity is measured in tons of refrigeration (TR). One TR is the amount of heat that is required to be extracted from one ton of water at 0°C in order to convert it into equivalent ice at 0°C in a day. | Comments | Active | |

| 25 | Which of the refrigerant has lowest freezing temperature? | Carbondioxide | Ammonia | Freon 12 | Freon 22 | d | Freon 12: -256 \(℃\) | Comments | Active | |

| 26 | Refrigerant R134a falls in the class of | Chloro Flouro Carbons | Hydro Chloro Fluoro Carbons | Hydro Flouro Carbons | Hydro Carbons | d | Designation of refrigerant = \(C_{a}H_{b}F_{c}Cl_{d}\) Designation = R (a-1)(b+1)c Given refrigerant is R134a so, from above equation we get: a=2, b = 2, c= 4 And for getting the value of d we apply expression = b + c + d = 2a + 2 From above equation we get d = 0 Hence there is no chlorine present in above refrigerant. So the answer will be option (c). |

Comments | Active | |

| 27 | By-pass factor in air conditioning is given by, | \(\frac{T_{c}-T_{s}}{T_{a}-T_{s}}\) | \(\frac{T_{a}-T_{s}}{T_{c}-T_{s}}\) | \(\frac{T_{c}-T_{s}}{T_{a}+T_{S}}\) | 1 + contact factor (Where, Surface temperature of cooling air, , Outlet temperature) \(T_{s}=\) \(T_{A}=Inlet temperature \) \(T_{c}=\) |

a | By pass factor is defined as the ratio of loss in cooling or heating to the ideal cooling or heating. | Comments | Active | |

| 28 | In air conditioning system, during dry climate, the range of sensible heat factor is | 0.08 to 0.09 | 0.1 to 0.2 | 0.3 to 0.4 | 0.75 to 0.80 | d | Comments | Active | ||

| 29 | In window AC, | Installation is not easy compared to split AC | Compressor and evaporator both are in one unit | There is no noise | None of the above | b | Central air conditioning (or central A/C) is a system in which air is cooled at a central location and distributed to and from rooms by one or more fans and ductwork. The work of the air conditioner compressor is what makes the whole process of air conditioning possible. | Comments | Active | |

| 30 | The capacity of a refrigerator is 120 ton and COP is 10. The power required to run the refrigerator is | 38 Kw | 42 kW | 45 kW | 48 kW | b | Given R.E =120 \(×3.5=420 kW\) COP = 10 \(COP=\frac{R.E}{W} \) 10 = \(\frac{420}{W}\) \(W=\frac{420}{10}=42 kW\) |

Comments | Active | |

| 31 | Round the clock cooling of an apartment having a load of 300 MJ/day requires an air-conditioning plat of capacity about | 1 ton | 5 ton | 10 ton | 25 ton | a | 1 T refrigeration = 3.5 kW Refrigerating capacity = (300 MJ/day)/3.5 = \(\frac{300×10^{3}}{3.5×24×3600}=1ton\) |

Comments | Active | |

| 32 | In a one ton capacity water cooler, water enters at 30 at the rate of 200 lit/h. Taking specific heat of water at 4.16 kJ/kgK, the outlet temperature of water will be \(℃\) | \(3.5℃\) | \(6.3℃\) | 23.7 \(℃\) | 15 \(℃\) | d | Cooling capacity = 1 ton = 3.5kJ/s = 3.5x3600 kJ/hour Let t is the outlet temperature of water Mass of water = density x volume = 1000 x 200 x 10-3 kg/hour = 200 kg/hr Applying energy balance 3.5 × 3600 = 4.16 × 200 (30 - t) ∴ t = 15°C |

Comments | Active | |

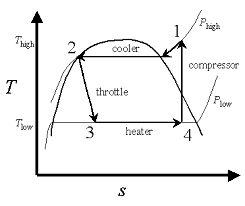

| 33 | During which component of vapour compression refrigeration system, the enthalpy remains constant? | Condenser | Throttle valve | Evaporator | Compressor | b | Throttling is a process where a high-pressure fluid is converted into low-pressure by using a throttle valve. In a throttling process, the enthalpy remains constant and the work done is zero. | Comments | Active | |

| 34 | Which of the following aspect is not true in the context of dry compression in a vapour compression refrigeration cycle? | Increase in refrigerating effect | Increase in power consumption | Improvement in coefficient of performance | Complete evaporation in the evaporator | c | Dry compression means that the entry point to the compressor is from saturated vapour and outlet of the compressor is a superheated vapour. For the same pressure ratio work required for the compressor is increased in dry compression. | Comments | Active | |

| 35 | A reversible engine has ideal thermal efficiency of 30%. When it is used as a refrigerating machine with all other conditions unchanged, the coefficient of performance will be | 1.33 | 2.33 | 3.33 | 4.33 | b | Given \(η=0.3\) COP (h.p) = COP (h.p) = 3.33 \(\frac{1}{η}\) COP (ref) = 3.33-1 \(COP(ref)=2.33\) |

Comments | Active | |

| 36 | In a mechanical refrigeration system, the refrigerant has the maximum temperature | In evaporator | Before expansion valve | Between compressor and condenser | Between condenser and evaporator | c | You can refer the below diagram. |

Comments | Active | |

| 37 | The condition of refrigerant as it leaves the compressor in a vapour compression system is | Saturated liquid | Wet vapour | Dry saturated vapour | Superheated vapour | d | In a vapor compression system, the condition of refrigerant before entering the compressor is the dry saturated vapor. At the end of the compressor or entry point of the condenser, the state of refrigerant is superheated vapor. | Comments | Active | |

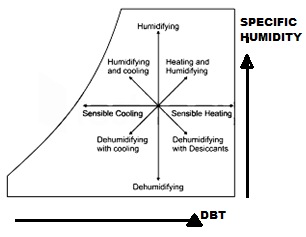

| 38 | The specific humidity during heating and humidification process | Remains constant | Increases | Decreases | None of the above | b | You can see the result. |

Comments | Active | |

| 39 | The COP of a domestic refrigerator | Is less than 1 | Is more than 1 | Is equal to 1 | Depends upon atmospheric conditions | b | The COP of a domestic refrigerator is the ratio of the refrigeration capacity to the energy supplied to the compressor. The COP of a domestic refrigerator is more than 1 |

Comments | Active | |

| 40 | Refrigeration in aeroplane usually employs the following refrigerant | CO2 | Freon-11 | Freon-22 | Air | d | Aircraft air refrigeration systems are required due to heat transfer from many external and internal heat sources (like solar radiation and avionics) which increase the cabin air temperature. | Comments | Active | |

| 41 | Which type of compressor is commonly used in room air-conditioner? | Reciprocating | Rotary | Screw | Centrifugal | b | In Rotary compressors a pair of specially designed rotors rotate in opposite directions making the air to get trapped between causing compression. All types of room air conditioners – window, split, portable use rotary compressor. | Comments | Active | |

| 42 | A refrigerant cycle is usually: | Open cycle | Closed cycle | Mixed cycle | Hybrid cycle | b | Like vapour compression refrigeration cycle. | Comments | Active | |

| 43 | A refrigerant should have | High specific heat | High Specific Volume | High Latent heat | High Boiling point | c | 1. Saturation pressure should be above or equal to the atmospheric pressure. 2. Latent heat evaporation high. 3. Refrigerant should be chemically stable. 4. It should not be nonflammable. 5. It should be non-toxic. 6. It should have low specific heat. 7. It have good thermal conductivity. 8. Eco-friendly. |

Comments | Active | |

| 44 | The dehumidification of air will change its: | Dry bulb temperature | Wet bulb temperature | Humidity Ratio | All of the above | c | The process in which the moisture or water vapor or the humidity is removed from the air keeping its dry bulb (DB) temperature constant and reduces the humidity ratio is called as the dehumidification process. | Comments | Active | |

| 45 | The instrument used for measuring the psychrometric properties of air is known as: | Thermometer | Hydrometer | Psychrometer | Pyrometer | c |  |

Comments | Active | |

| 46 | The common refrigerant used in domestic refrigerator is: | Ammonia | Sulphur dioxide | Freon | Carbon dioxide | c | R-12 or Freon 12 is used in domestic refrigerators and freezers, liquid chillers, dehumidifiers, ice makers, water coolers, water fountains and transport refrigeration. | Comments | Active | |

| 47 | In an Otto cycle, the temperature at the end of compression and at the end of heat addition processes are 600 K and 1600 K respectively. The efficiency of Otto cycle is 60%. Specific heat at constant volume is 0.70 kJ/kg. Work done per kg of cycle is | 316 Kj | 359 kJ | 420 kJ | 446 kJ | c | Given ; \(T_{2}=600 K\) \(T_{1}=1600K\) \(η=0.6\) \(C_{V}=0.70 kJ/kg\) As you know that the \(η=\frac{W}{Q_{1}}\) \(W=0.6Q_{1}\) W = \(0.6 C_{v}(T_{1}-T_{2})\) \(W=0.6 ×0.70×(1600-600)\) \(W=420 kJ\) |

Comments | Active | |

| 48 | An accessory of boiler is | Air preheater | Feed check valve | Stop valve | Blow-off cock | a | The purpose of the air preheater is to recover the heat from the boiler flue gas which increases the thermal efficiency of the boiler by reducing the useful heat lost in the flue gas. | Comments | Active | |

| 49 | In case of Parson’s reaction turbine, the degree of reaction is: | 0.0 | 0.5 | 1.0 | 1.5 | b | Degree of reaction may also be defined as the ratio of enthalpy drop in the rotor to the enthalpy drop in the stage. For Parson’s Reaction turbine R = 0.5, and for Hero’s turbine R = 1 | Comments | Active | |

| 50 | In a Diesel engine cycle, compression ratio is 12 and cut off is 6 percent of stroke. The cut-off ratio is: | 1.24 | 1.36 | 1.45 | 1.66 | d | Given Compression ratio (= 12cut off is 6% of stroke = 0.06 \(r_{c}) \) Cut off ratio ( = 1 + 0.06 ( \(Ï)\) \(r_{c}-1)\) \(Ï=1+0.06×11=1.66\) |

Comments | Active | |

| 51 | Clearance volume in a cylinder of engine should be: | As large as possible | As small as possible | About 50 percent of swept volume | None of these | b | Clearance volume or bumping clearance is the space between the top of the piston and the cylinder head of an air compressor. This clearance is an important aspect of the compressors and should be as less as practically possible to improve the volumetric efficiency of the compressor. The clearance volume should not be too less or too more. | Comments | Active | |

| 52 | The volumetric efficiency of a reciprocating compressor which compresses air from pressure to (index of compression n) is \(p_{1}\) \(p_{2}\) |

\(1+k-k(\frac{p_{2}}{p_{1}})^{\frac{1}{n}}\) | \(1-k+k (\frac{p_{2}}{p_{1}})^{\frac{1}{n}}\) | \(1+k-k(\frac{p_{1}}{p_{2}})^{\frac{1}{n}}\) | \(1-k+k(\frac{p_{1}}{p_{2}})^{\frac{1}{n}}\) Where k, is clearance ratio. |

a | \(η_{vol}=1+k-k(\frac{p_{2}}{p_{1}})^{\frac{1}{n}}\) | Comments | Active | |

| 53 | A single stage impulse turbine is generally not used in practical because | It cannot generate more power | Heat energy is not utilized fully | It has very low efficiency | It needs large reduction gearing due to high speeds | d | It is the first working impulse turbine. It consists of a single set of the nozzle and moving blades. Therefore, total pressure drop from boiler pressure to condenser pressure takes place in a single nozzle which gives high rotational speed exceeding pressure limit of 3000 rpm. This turbine is generally not used in practical because it needs large reduction gearing due to high speeds. | Comments | Active | |

| 54 | Compounding of a steam turbine is done to | Balance the rotor | Reduce the blade friction | Reduce the rotor speed | Connect the shaft of one turbine to that of another | c | Compounding of steam turbine is used to reduce rotor speed. It is the process by which rotor speed come to its desired value. A multiple system of rotors are connected in series keyed to a common shaft and the steam pressure or velocity is absorbed in stages as it flows over the blades. | Comments | Active | |

| 55 | Which is not the common component between a petrol and a diesel engine? | Cam shaft | Exhaust silencer | Spray nozzle | Dynamo | c | Nozzle is that part of an injector through which the liquid fuel is sprayed into the combustion chamber. It is used in Diesel engine in which fuel is drawn separately through injector at end of compression stroke and air is drawn into cylinder in suction stroke. | Comments | Active | |

| 56 | Which type of the engine most cars have? | Two stroke cycle engine | Four stroke cycle engine | Rotary Wankel engine | Free piston engine | b | Most cars have four stroke cycle engine. | Comments | Active | |

| 57 | Which of the following is a fire tube boiler? | Locomotive boiler | Babcock and Wilcox boiler | Stirling boiler | All of the above | a | Locomotive boiler is a fire tube, multi-tubular boiler which has a horizontal drum axis. The circulation in this boiler is natural and it is a medium pressure boiler. | Comments | Active | |

| 58 | A fusible plug is fitted in small boilers in order to | Avoid excessive buildup of pressure | Avoid explosion | Extinguish fire if water level in the boiler falls below alarming limit | Remove molten ash | c | The aim of a fusible plug is to shield the boiler from damage caused by low water levels overheating the boiler tubes. | Comments | Active | |

| 59 | The action of steam in a steam turbine is | Static | Dynamic | Static and dynamic both | Neither static nor dynamic | b | A steam turbine works on the dynamic action of steam. Steam is caused to fall in pressure in a passage or nozzle. Due to this fall in pressure, certain amount of heat energy is converted into kinetic energy to give it high velocity. | Comments | Active | |

| 60 | In petrol engine, if diesel is used, then the engine will | Not run | Run more efficiently | Run at high speed | Explode | a | If we add diesel in petrol engine then it will not run but if we will add petrol in diesel engine then it will explode. | Comments | Active | |

| 61 | In a single acting reciprocating air compressor, without clearance, the compression of airmay be | Isothermal | Polytropic | Isentropic | Any one of the above | c | In actual practice, the isothermal compression is not possible, since, it requires the compression process very slow in the order it maintains a constant temperature. So the correct option will be option (c). | Comments | Active | |

| 62 | Carburetion is done to | Feed petrol to cylinder | Govern the engine | Breakup and mix the petrol with air | Scavenge the cylinder | c | Carburetion: It is the job of the carburetor to regulate how much fuel and air gets mixed so that you get the proper combustible mixture. | Comments | Active | |

| 63 | The thermal efficiency of a diesel engine is of the order of: | 92% | 68% | 52% | 34% | b | The thermal efficiency of petrol and gas engines is about 30% and the thermal efficiency of diesel engines is about 70%. | Comments | Active | |

| 64 | The thermal efficiency of a gas engine is of the order of: | 92% | 52% | 34% | 25% | b | Modern gasoline engines have a maximum thermal efficiency of more than 50%, but road legal cars are only about 20% to 35% when used to power a car. | Comments | Active | |

| 65 | The number of fire tubes in Lancashire Boiler is | One | Two | Four | Six | b | There is two fire tubes in Lancashire boiler and one fire tube in Cornish boiler. | Comments | Active | |

| 66 | Mechanical efficiency of Gas turbine as compared to IC Engine is | Higher | Lower | Same | Depends on other considerations | a | Due to rotating components in IC engine there is more friction losses in IC engine as compared to Gas turbine so the efficiency of Gas turbine is more than the efficiency of IC engine. | Comments | Active | |

| 67 | The Air-fuel ratio in gas turbine is of the order of | 7:1 | 15:1 | 30:1 | 50:1 | d | In a gas turbine cycle the energy is put into the system by burning fuel in flowing gas. The combustion is maintained in a stream of air moving with a high velocity in the region of 30-60 m/s. The air-fuel ratio vary from 60 : 1 to 120 : 1. The stoichiometric ratio is approximately 15 : 1. | Comments | Active | |

| 68 | Kerosene is distilled at | 30 - 65 \(℃\) | \(65-220℃\) | \(220-350℃\) | \(350-450℃\) | c | Kerosene is distilled at 220-350ºC and petrol is distilled at a temperature in range of 65-220ºC. | Comments | Active | |

| 69 | The maximum working pressure of fire tube boiler is limited to: | 1.5 kgf/cm2 | 5 kgf/cm2 | 20 kgf/cm2 | 100 kgf/cm2 | c | As per given option, option (c) will be correct. | Comments | Active | |

| 70 | For the safety of the boiler, which of the mounting is provided more than one in number: | Fusible Plug | Safety valve | Feed Check valve | Steam Stop Valve | b | Each boiler shall be equipped with two safety valves for relieving the steam pressure. The diameter of the valve shall not be less than 19 mm. | Comments | Active | |

| 71 | The operation of Impulse steam turbine depends on the: | Pressure energy of steam | Kinetic energy of steam | Datum energy of steam | None of these | c | Impulse turbines are defined as turbines in which high-velocity jets of water or steam collide with the blades of the turbine to rotate the turbine and produce electricity using this winding. | Comments | Active | |

| 72 | In reaction steam turbine the expansion of steam takes place inside the: | Moving blades | Fixed blades | Fixed as well as moving blades | Nozzles | c | Sol. In reaction steam turbine the expansion of steam takes place inside the fixed as well as moving blades. | Comments | Active | |

| 73 | In two stroke engine, the number of power strokes are equal to: | Number of revolutions per minute of crank shaft | Twice the number of revolutions of crank shaft | Half the number of revolutions of crank shaft | Four times the number of revolutions of crank shaft | a | Comments | Active | ||

| 74 | Rotary compressor are used for producing: | Large quantity of air at high pressure | Large quantity of air at low pressure | Small quantity of air at low pressure | Small quantity of air at high pressure | b | A rotary compressor is a compressor that compresses the gas by the rotary motion of the roller in an enclosed cylinder. Rotary compressors are used where large quantities of air or gas are needed at relatively low pressure. | Comments | Active | |

| 75 | In two stage compressor, when will the efficiency be maximum? | \(p_{2}=p_{1}×p_{3}\) | \(p_{2}=\frac{p_{1}}{p_{3}}\) | \(p_{2}=p_{1}×p_{3}\) | \(p_{2}=p_{1}+p_{3}\) (Where, Initial pressure, = Pressure after first stage, = Final pressure) \(p_{1}=\) \(p_{2}\) \(p_{3}\) |

c | For maximum efficiency \(p_{2}=p_{1}×p_{3}\) |

Comments | Active | |

| 76 | In a gas turbine, the air is compressed to a pressure of: | 3 to 6 kgf/cm2 | 30 to 60 kgf/cm2 | 0.3 to 0.6 kgf/cm2 | 10 to 15 kgf/cm2 | d | Comments | Active | ||

| 77 | In a sand casting, core is used to | Make desired recess in casting | Strengthen moulding sand | Support loose pieces | Remove pattern easily | a | A core is a preformed, bonded, sand insert placed into the mold to shape the interior of a casting or a part of the casting that cannot be shaped by the pattern. | Comments | Active | |

| 78 | Large size bolt heads are made by | Swaging | Roll forging | Upset forging | Blanking | c | Upset forging involves locally heating a metal bar and then, while holding it firmly with special tooling, applying pressure to the end of the bar in the direction of its axis to deform it. | Comments | Active | |

| 79 | In sheet metal shop, tool made up of hardened steel which is used for marking out and to locate the centre in a permanent manner is | Divider | Punch | Trammel | Stake | b | Trammel heads are marking out tools primarily used to draw large circles or arcs. They are sometimes called trammel points, or trammels. | Comments | Active | |

| 80 | A mandrel is | A slightly tapered hardened steel shaft that supports works which cannot be supported otherwise | a tapered gauge used for inspection of tapered holes | Auxiliary chuck used on lathe for holding small loads | used in lathe work to hold castings | a | Mandrel is used to support a partly machined workpiece while it is being finished, or as a core around which parts may be bent or other material forged or molded. | Comments | Active | |

| 81 | A knee is a part of the following: | Lathe machine | Shaper machine | Milling machine | Jig Boring machine | c | Milling machine is used to cut slots, grooves, and drill and perform all operation like to shape the workpiece. The basic milling machine parts are base, column, arbor, knee, saddle, table, overhanging arm, elevating screw, ram etc. These parts are responsible for proper working of milling machine. | Comments | Active | |

| 82 | While machining a brass casting on a lathe, the type of chuck used is | Collet chuck | Magnetic chuck | Three jaw chuck | Four jaw chuck | d | We can use a 4 jaw chuck lathe to safely hold square, hexagonal, wound, and irregular-shaped workpieces, with the independent movement of the jaws enabling accurate adjustment. | Comments | Active | |

| 83 | In a centreless grinding, the workpiece advances by | Push given by operator | Hydraulic force | Force exerted by grinding wheel | Force exerted by regulating wheel | d | Centerless grinding is the process of removing material from the outside diameter of a work piece using an abrasive wheel. In its simplest form, a centerless grinder consists of the machine base, grinding wheel, regulating wheel and work blade. | Comments | Active | |

| 84 | To clean a hand file, | It is dipped in water | It is dipped in dilute acid | It is rubbed on stone | File card is used | d | A file card brush is used to clean a file to ensure longer life and efficiency. A file is a hand tool used in metalwork, woodwork and plastic work. | Comments | Active | |

| 85 | Cementide carbide tools are generally poor in the following conditions | Compression | Tension | Shear | Torsion | b | Cementide carbide tools are generally poor in the tension conditions. | Comments | Active | |

| 86 | DIN specifications have been developed in | Germany | Russia | England | America | a | DIN stands for Deutsches Institute for Normung German [German Institute for Standardization] The DIN began in Berlin in 1917. Its initial purpose was quality assurance with the aim to improve global communication. | Comments | Active | |

| 87 | In tool signature, the nose radius is indicated | In the first position | In the last position | In the middle | Second from last | b | Designation of tool \(α_{b}-α_{s}-c_{e}-c_{s}-γ_{e}-γ_{s}-R\) |

Comments | Active | |

| 88 | Lathe bed is usually made of | Structural steel | Stainless steel | Cast iron | Mild steel | c | Cast iron is commonly used for machinery housings or base due to its damping characteristics. It is also known for holding its shape when it is subjected to contraction and expansion due to temperature fluctuations. | Comments | Active | |

| 89 | Size of shaper is equal to | Length of stroke | Size of table | Maximum size of tool | Ratio of forward to return stroke | a | The size of the shaper is specified by the maximum length of stroke or cut it makes. The maximum stroke length of the shaper is 900 mm. | Comments | Active | |

| 90 | Feed rate in milling operation is specified by | RPM | RPM No. of teeth \(×\) | RPM Feed per tooth No. of teeth \(×\) \(×\) | None of the above | c | Feed rate = RPM Feed per tooth \(×\) \(×No.of teeth\) | Comments | Active | |

| 91 | For drilling operation, the cylindrical job should always be clamped on a | Collet | Jaw | Vise | V-block | d | V-Blocks are precision metalworking jigs typically used to hold round metal rods or pipes for performing drilling or milling operations. | Comments | Active | |

| 92 | For ferrous metal, the helix angle of drill is | \(30°\) | \(45°\) | \(60°\) | 90 \(°\) | a | For ferrous metal, the helix angle of drill is 30° | Comments | Active | |

| 93 | In grinding, for faster removal of metal: | Fine grain size is used | Medium grain size is used | Coarse grain size is used | Any grain size is used | c | A larger grain will cut freely, allowing fast cutting but poor surface finish. Ultra-fine grain sizes are for precision finish work. | Comments | Active | |

| 94 | A sprue hole is | A casting defect | A hole made for riveting | A blind hole in jigs | An opening in mould for pouring molten metal | d | In casting, a sprue is the passage through which a molten material is introduced into a mold. | Comments | Active | |

| 95 | Which wood can be used for making patterns? | Mahogany | Pine woods | Teak wood | all of the above | d | All the given wood are used for making patterns. | Comments | Active | |

| 96 | Which of the following is a screen? | Shovel | Riddle | Sand hammer | Slick | b | Riddle is a screen | Comments | Active | |

| 97 | Sand is generally specified by its | Grain size | color | Moisture content | all of the above | a | Grain size (or particle size) is the diameter of individual grains of sediment, or the lithified particles in clastic rocks. The term may also be applied to other granular materials. | Comments | Active | |

| 98 | The appearance of Laser beam is | Greenish | Reddish | Yellowish | Whitish | b | Comments | Active | ||

| 99 | In Electro-Discharge Machining (EDM), the commonly used material of the tool is | High speed steel | Brass or copper | Carbide | Diamond | b | Brass and copper is used as an copper electrode for EDM. | Comments | Active | |

| 100 | The cathode (tool) and the anode (workpiece) in Electro Discharge Machining (EDM) are separated by | A dielectric fluid | An electrolyte | An insulating material | None of the above | a | Electro discharge machining (EDM) is based on melting and vaporization principle. In EDM process sufficient direct current (DC) voltage is applied between two electrodes, i.e., tool and workpiece separated by a dielectric fluid like kerosene. | Comments | Active | |

| 101 | The type of chip obtained by machining hard and brittle material is: | Continuous chip with built up edge | Continuous chip | Discontinuous chip | Inhomogeneous chip | c | Discontinuous chip obtained by machining hard and brittle material while continuous chip obtained by machining tough and soft material. | Comments | Active | |

| 102 | Which one of the following materials will require the largest size of riser for the same size of casting? | Aluminium | Cast iron | Steel | Copper | a | Aluminium shows maximum liquid shrinkage. | Comments | Active | |

| 103 | The metal moulds are used in | Green sand mould | Dry sand mould | Die casting process | Loam moulding | c | Comments | Active | ||

| 104 | A body of sand used in a mould to form a hole or recess in a casting is known as: | Core | mould | Core box | None of these | a | A core is a preformed, bonded, sand insert placed into the mold to shape the interior of a casting or a part of the casting that cannot be shaped by the pattern. Cores are frequently used to create hollow sections or cavities in a casting. | Comments | Active | |

| 105 | The ultrasonic welding is suitable for metal upto: | 3 mm thick | 5 mm thick | 8 mm thick | 10 mm thick | a | Comments | Active | ||

| 106 | Tools in the case of ultrasonic machining are made of | HSS | Diamond | Plain Carbon | Brass or Copper | d | Ultrasonic machining is a nontraditional process. In this process abrasives contained in the slurry are driven against the work by a tool oscillating at low amplitude (25–100 microns) and high frequency (15–30 kHz) Tools are made of relatively ductile materials like brass, stainless steel or mild steel so that tool wear rate (TWR) can be minimized | Comments | Active | |

| 107 | Maximum friction is caused in | Up milling | Down milling | End milling | Climb milling | a | In which the cutter and feed move in the opposite direction i.e the rotary cutter moves against the feed due to this opposite motion, the width of the cutting chips gradually increases from minimum to maximum. There is massive friction between the cutter and workpiece which results in generating a large amount of heat. | Comments | Active | |

| 108 | The axis of cutter rotation is parallel to the workpiece surface to be machined in | Up milling | End milling | Plain milling | Face milling | c | Plain milling, also known as surface or slab milling, refers to milling operations in which the cutting tool's axis of rotation is parallel to the surface of the workpiece. The process employs plain milling cutters which have teeth on the periphery that perform the cutting operation. | Comments | Active | |

| 109 | The common value of point angle in standard drill is | \(90°\) | 100 \(°\) | 118 \(°\) | 122 \(°\) | c | Comments | Active | ||

| 110 | The helical groove in the drill body is known as | Flute | Tang | Web | Heel | a | In the drill body the flutes are the spiral grooves which run to the length of the drill; the flutes help to form the cutting edges. |

Comments | Active | |

| 111 | Commonly used abrasives materials are | Mica, glass, asbestos | Alumina, silicon carbide and boron nitride | Clay, quartz and borosilicate | Oxide of magnesium, kaolin and feldspar | b | Abrasive materials are hard crystals that are either found in nature or manufactured. The most commonly used of such materials are aluminum oxide, silicon carbide, cubic boron nitride, and diamond. | Comments | Active | |

| 112 | For cutting internal and external gear teeth, machine used is | Planer | Shaper | Slotter | Milling | c | The slotter machine is used for i. Cutting grooves, keyways and slots of various shapes. ii. Used for making regular and irregular surfaces both internal and external. iii. For handling large and awkward workpiece. iv. For cutting internal or external gears and many other operations which cannot be easily machined in any other machine tool described before. |

Comments | Active | |

| 113 | Which part of the cutting tool is prone to crater wear? | Flank | Face | Shank | Base | b | Crater wear occurs on the rake face of the tool, while flank wear occurs on the relief (flank) face of the tool. | Comments | Active | |

| 114 | Cutting tools may be provided with large positive rake angles to | Have better heat dissipation | Avoid rubbing with the finished surface | Increase the strength of cutting edge | Reduce the magnitude of cutting force | d | Cutting tools are provided with a large positive rake angle mainly for reducing the magnitude of the cutting force. | Comments | Active | |

| 115 | The cutting speed in turning operation would be least in case of | Aluminium alloys | Medium carbon steel | Mild steel | Stainless steel | d | Comments | Active | ||

| 116 | Discontinuous or segmental chips are produced during machining of | Cast iron | Mild steel | Copper | High Carbon Steel | a | Continuous chips are not produced during the machining of Cast iron. Discontinuous chips are usually formed during machining of brittle materials like cast iron. The low cutting speed and small rake angle of the tool are responsible for the formation of discontinuous chips. | Comments | Active | |

| 117 | No cutting fluid is normally used while machining of following material | Aluminium | Alloy steel | Cast iron | Low carbon steel | c | No cutting fluid is normally used while machining cast iron because of the self-lubricating property of graphite present in cast iron. Lubrication in cast iron is dry or compressed air. | Comments | Active | |

| 118 | The tool life is influenced maximum by the following: | Cutting speed | Tool material and geometry | Cutting fluid | Surface conditions of the workpiece | a | The sequence of parameters affecting tool life is: Cutting speed > Feed > Depth of Cut. Tool life is defined as the time interval between two successive regrinds. | Comments | Active | |

| 119 | the most important requisite of a cutting tool material is | Carbon percentage | Percentage of alloying elements | Red (hot) hardness | Easy fabrication | c | Hot or Red Hotness: It is the ability of the cutting tools to withstand high temperatures without losing its cutting edge. | Comments | Active | |

| 120 | The cutting force at the cutting edge of a tool during machining of metal is measured by | Dynamometer | Odometer | Bolometer | kentometer | a | Dynamometers are devices used to measure cutting forces in machining operation. | Comments | Active | |

| 121 | Identify the method which can be used for turning external tapers only. | Form tool | Compound test | Taper attachment | Tailstock offset | d | Taper Turning with Tailstock set over Method: This method is employed for turning small tapers on longer jobs and is confined to external tapers only. | Comments | Active | |

| 122 | Friction between chip and tool can be reduced by | Increasing rake angle | Increasing shear angle | Increasing depth of cut | Increasing sliding velocity | a | By increasing the rake angle, chip flow will be easier and the friction will reduce. | Comments | Active | |

| 123 | A hacksaw blade is specified by its | Length | Materials | Width | Number of teeth | a | Hacksaw frame is used along with a blade to cut metals of different sections and is specified by the type and maximum length of the blade that can be fixed. The distance between the adjacent teeth is known as the pitch of the blade. | Comments | Active | |

| 124 | Best coolant and lubricant for cast iron is | Water soluble oils | Mineral fatty acids | Soluble oils | None of the above | d | Comments | Active | ||

| 125 | Buffing is an operation of | Cleaning castings | Depositing metal by spraying | Broaching in reverse direction | Producing luster on metal surface | d | Buffing is a surface finishing process, which is performed after polishing for providing a high luster to be polished surface. Buffing is a surface finishing process used to shine wood, metal, or composites using a wheel generally made up of cotton. | Comments | Active | |

| 126 | Drilling is an example of | Simple cutting | Uniform cutting | Orthogonal cutting | Oblique cutting | d | Drilling is oblique cutting because the angles of threads on drill bit are at an angle less than 90 degree. | Comments | Active | |

| 127 | Function of Jig is | To hold and locate the workplace | To guide the tool | Both (a) and (b) | None of the above | c | A jig is a type of tool used to control the location and/or motion of another tool. A jig's primary purpose is to provide repeatability, accuracy, and interchangeability in the manufacturing of products. A device that does both functions (holding the work and guiding a tool) is called a jig. | Comments | Active | |

| 128 | Fixture are used in | Milling | Drilling | Reaming | Tapping | a | Fixture are used for holding the work in milling, grinding, planning and turning operations. | Comments | Active | |

| 129 | Which is the manufactured abrasive material? | Sandstone | Diamond | Silicon Carbide | Garnet | c | Artificial abrasives are silicon carbide and aluminium oxide. | Comments | Active | |

| 130 | The drill size for tapped hole is given by the relation: | D = (T - d) | D = (T + d) | D = (T – 2d) | D = (T+ 2d) (Where, D = Drill size, T = Diameter of tape, d = Depth of hole) |

c | Comments | Active | ||

| 131 | The machine is used for machining flat surfaces of large size is: | Lathe | Milling | Planer | Shaper | c | Planer is used for the purpose of machining too large and heavy jobs. There is a table in planer known as platen on which the work piece is fixed firmly and the operation is performed. | Comments | Active | |

| 132 | The shaper is used for machining of: | Flat surfaces | Cylindrical surfaces | Spherical surfaces | All of the above | a | Shaper is a reciprocating type of machine tool in which the ram moves the cutting tool backwards and forwards in a straight line. These surfaces may be horizontal, vertical, or inclined In general, the shaper can produce any surface composed of straight line elements. | Comments | Active | |

| 133 | In a planer | The work is mounted on a table which reciprocates and tool is held rigid on the machine frame | The tool is held on a ram which reciprocates and the work is mounted on a stationary motion | Both the tool as well as the work have reciprocating motion. | Both the tool as well as the work have rotatory motion | a | Planer is a machine tool used for producing accurate flat surfaces and cutting slots. Table supports the work and reciprocates along with the ways of the bed the table is made up of high quality cast iron. | Comments | Active | |

| 134 | The front clearance angle of a shaper tool is: | \(4°\) | 15 \(°\) | 25 \(°\) | 35 \(°\) | a | Usually shaper tool is given a front clearance angle of 4 degrees and side clearance angle of 2 or 3 degrees. If front clearance is high, then the cutting edge will not be strong because of lack of supporting metal and tool may dull quickly or crumble. | Comments | Active | |

| 135 | The lathe is a machine that removes material by ------- | Feeding the work against a rotating cutter | Rotating the work against cutter | Rotating the work against a rotating cutter | Feeding the work against a cutter having reciprocating motion | b | Lathes are designed to remove material from workpieces by exposing them to a cutting tool. The workpiece is secured to the lathe, at which point it rotates while pressing into a cutting tool. The rotational movement of the workpiece allows for the fast, efficient and precise removal of material. | Comments | Active | |

| 136 | Forging process | Eliminates porosity and blow holes | Can be used to produce complicated shapes | Give elastic deformation for shaping | Uses continuous compressive force | * | Forging is the process by which a metallic part is deformed to final shape with the application of pressure and with or without the application of heat. It involves the application of compressive stress which exceeds the flow stress of the metal. This stress is applied either quickly or slowly. | Comments | Active | |

| 137 | The process of putting a rod through several dies of decreasing diameter is known as | Rolling | Stretch forming | Trimming | Wire drawing | d | Wire drawing is a metalworking process used to reduce the cross-section of a wire by pulling the wire through a single, or series of, drawing dies. | Comments | Active | |

| 138 | Spot of odd one out | Forging | Cold rolling | Swaging | Hot extrusion | b | Cold rolling is a process by which metal is passed through rollers at temperatures below its recrystallization temperatures. | Comments | Active | |

| 139 | The size of a press is specified by the following: | Weight of the process | Size of the workpiece it can handle | Maximum load that can be applied to the workpiece | Power required to operate the machine | c | The size of any press is determined by the maximum force or pressure that can be exerted by the ram on the work piece without any failure. | Comments | Active | |

| 140 | Which is the most widely used metal for castings? | Aluminum | Brass | Magnesium alloys | Cast iron | d | Gray iron is one of the most frequently used casting materials in industrial manufacturing. Accounting for a large portion of casting supply markets, it is a strong, versatile substance. | Comments | Active | |

| 141 | Disposable patterns are made of | Wood | Rubber | Metal | Polystyrene | d | Disposable pattern: A pattern which instead of being removed from the mould gets burnt and evaporated when the molten metal is poured into the mould | Comments | Active | |

| 142 | Two streams of metal that are not hot enough to fuse properly, result into a casting defect known as: | Cold shots | Swell | Shrinkage | Sand wash | a | A cold shut is a fault in the surface of a piece of metal caused by two streams of molten metal not joining properly when the piece is being cast. | Comments | Active | |

| 143 | The mode of deformation of the metal during spinning is | Bending | Stretching | Rolling and Stretching | Bending and Stretching | d | In spinning methods, a polymer solution or melt is extruded through a spinneret by the action of an external force, forming jets of stretched fibers that solidify by either drying or solidification. | Comments | Active | |

| 144 | Metal patterns are used for | Small castings | Large castings | Complicated castings | Large scale production of castings | d | The metal patterns are durable: they undergo very less abrasion due to mold sand So they are used for large quantity of casting. | Comments | Active | |

| 145 | The sand used for making cores is | Green sand | Dry sand | Loam sand | Oil sand | d | Oil sand is used for making cores and it is sometimes also known as oil sand Core sand is highly rich silica sand mixed with oil blinders such as core oil which composed of linseed oil, resin, light mineral oil and other bind materials. | Comments | Active | |

| 146 | Which of the following welding process uses non-consumable electrodes? | TIG welding | MIG welding | Manual arc welding | Submerged arc welding | a | Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW) is an arc welding process that produces the weld with a non-consumable tungsten electrode. | Comments | Active | |

| 147 | Green sand is a mixture of | 30% sand and 70% clay | 50 % sand and 50% clay | 70% sand and 30% clay | 90% sand and 10% clay | c | Green sand is a mixture of 70% sand and 30% clay. | Comments | Active | |

| 148 | Coining is the operation for | Cold forging | Hot forging | Cold extrusion | Piercing | a | Coining is a cold press working operation in which the starting material is in the form of a blank of sheet metal. It is a pressing operation, it does not base on metal deformation. | Comments | Active | |

| 149 | The process extensively used for making bolts and nuts is | Hot piercing | Extrusion | Cold peening | Cold heading | d | Cold heading manufacturing is a multi-step process used to form metal parts at room temperature. Unlike other metal fabrication processes, hammers and dies are used at a high speed to form the metal without heating the material. | Comments | Active | |

| 150 | The piercing and punching operation, the angle of shear is provide on | Die | Punch | Both Punch and Die | None of the above | b | Punching is a process in which the punch removes a portion of material from the large piece or a strip of sheet metal. For the blanking operation, shear is provided on the die face and for piercing operation shear is provided on the punch face. | Comments | Active | |

| 151 | Powder metallurgy techniques are used in the production of | HSS tools | Tungsten Carbide tools | Twist drills | Ceramics | b | Tungsten Carbide Hard Metals are primarily produced using a Powder Metallurgy process, whereby the powdered forms of tungsten carbide and cobalt are mixed using ball mills, a binder material is added to hold the powders together during the next stage of the process which is compaction or pressing. | Comments | Active | |

| 152 | When a pattern is made in three parts, the top part is known as | Drag | Cheek | Cope | None of the above | c | When a pattern is made in three parts, the top part is known as cope, the middle part known as cheek and the bottom part is known as drag. | Comments | Active | |

| 153 | The property of sand due to which it evolves a great amount of steam and other gases is called | Collapsibility | Permeability | Cohesiveness | Adhesiveness | b | Permeability is a condition of porosity and thus is related to the passage of gaseous materials through the sand. | Comments | Active | |

| 154 | Open circuit voltage for Arc welding is of the order of | 18-40 volts | 40-95 volts | 100-125 volts | 130-170 volts | b | The selection of an optimum value of Open Circuit Voltage depends on the type of base metal, a composition of electrode coating, type of welding current and polarity, type of welding process etc. It generally varies from 50 V – 100 V |

Comments | Active | |

| 155 | The material used for coating the electrode is called | Protective layer | Binder | Slag | Flux | d | A flux coating is a layer of a chemical that acts as a cleaning agent, a purifying agent, or a flowing agent. It protects the weld pool and solid metal from atmospheric contamination and helps in removing impurities from the weld pool. | Comments | Active | |

| 156 | Weld Spalter is | Flux | Welding defect | Electrode coating | Welding test | b | Weld spatter is a welding defect while weld spelter is a flux. Here in question paper written work is “Weld Spalterâ€. If it is spatter then it is defect but if it is spelter then it is filler material. Weld spatter is not a correct word. | Comments | Active | |

| 157 | Grey cast iron is usually welded by following: | Gas welding | Arc Welding | TIG welding | MIG welding | a | Grey cast iron is welded by gas welding. In welding grey cast iron Neutral flame is used sometimes slightly oxidized flame can also be used for grey cast iron welding. | Comments | Active | |

| 158 | Oxygen to Acetylene ratio in case of neutral flame is | 0.8 : 1 | 1 :1 | 1.2 :1 | 2:1 | b | For Carburising or Reducing flame: oxygen to acetylene ratio is less than 1. For Oxidising flame: Oxygen to Acetylene ratio is greater than 1. For Neutral flame: Oxygen to Acetylene ratio is equal to 1. |

Comments | Active | |

| 159 | The mould is housed in a | Flask | Cope | Drag | Moulding box | * | The mould is housed in a molding flask or molding box. a and d both answer are correct. | Comments | Active | |

| 160 | Which of the following is not a casting process? | Cathias process | Extrusion | Slush process | Shell moulding | b | In Carthias process, the cavity is filled with a pre-calculated quantity of metal and a core or plunger is inserted to force the metal into the cavity. So here’s the option (b) is correct. Extrusion is not a casting process. | Comments | Active | |

| 161 | . Slag inclusion in casting is a | Surface defect | Internal defect | Crack | Notch | a | Slag inclusion in casting is a surface defect. | Comments | Active | |

| 162 | Which of the following material is used for making of pattern? | Aluminium | Plastics | Wax | All of the above | d | materials used for pattern making are wood, metal or plastics. Wax and Plaster of Paris are also used, but only for specialized applications. | Comments | Active | |

| 163 | The tool used for lifting the pattern from the mould is called: | Trowel | Slick | Lifter | Draw spike | d | A draw spike is a pointed tool at one end and loop at the other. It is driven into a wooden pattern and withdraw pattern from the mould. | Comments | Active | |

| 164 | In laser welding the heat is supplied by | The oxyacetylene gas | The electric arc | The collimated light beam | Inducing the current | c | Laser beam welding is a fusion welding process in which two metal pieces are joined together by the use of laser. The laser beam provides a concentrated heat source, focused to the cavity between the two metal pieces to be joined. | Comments | Active | |

| 165 | In electrical resistance welding the voltage of current is in the range of | 4 to 12 V | 25 to 50 V | 120 to 240 V | 240 to 444 V | a | The current is often in the range 1 000–100 000 A, and the voltage in the range 1–30 V. To achieve joining, resistance welding machines must go through three basic steps: 1. Clamping or pressing together the workpieces with a certain mechanical force and holding them in the correct position. | Comments | Active | |

| 166 | In thermit welding the high temperature is produced by: | An electric arc | An exothermal chemical reaction | The combustion of oxygen and acetylene | None of these | b | In thermit welding, heating and coalescence is by superheated molten metal obtained from a chemical reaction between a metal oxide and a metallic reducing agent. Temperature around 2750°C produced in 30 seconds. Thus it involves highly exothermic chemical reaction for developing high temperature. | Comments | Active | |

| 167 | A fluid is said to be ideal, if it is | Incompressible | Inviscous | Viscous and incompressible | Inviscous and incompressible | d | An ideal fluid is a fluid that is incompressible and no internal resistance to flow (zero viscosity). In addition ideal fluid particles undergo no rotation about their center of mass (irrotational). An ideal fluid can flow in a circular pattern, but the individual fluid particles are irrotational. | Comments | Active | |

| 168 | Hydraulic machines are devices that convert | Hydraulic energy into mechanical energy only | Mechanical energy into hydraulic energy only | Both a and b | None of the above | c | The hydraulic machines generally use a liquid fluid that is the power to perform work. | Comments | Active | |

| 169 | Specific speed of hydraulic turbine depends upon | Speed, power and discharge | Discharge and power | Speed and head | Speed, power and head | d | \( N_{S}=\frac{NP}{H^{5/4}}\) \( N=speed\) \(P=Power\) \(H=head\) |

Comments | Active | |

| 170 | Velocity of flow at inlet and velocity of flow at outlet is same in | Pelton turbine | Francis turbine | Kaplan turbine | None of the above | a | In Pelton turbine each blade has same angular velocity and same linear speed unlike Francis and Kaplan turbines. | Comments | Active | |

| 171 | Draft tube | Is mainly used in reaction turbine | Recovers the loss of head as runner exit | Is used in impulse turbine | Both a and b | d | Draft tube is one of the important component of reaction turbine and connects runner exit to tail race. The main functions of draft tube is to allow the installation of turbine above the tail race level without loss of head and to convert major part of kinetic energy coming out of runner into pressure energy. | Comments | Active | |

| 172 | The work requirement of a reciprocating pump with increase in acceleration head | Increases | Decreases | Remains same | none of the above | c | Acceleration head is a primary concern in reciprocating pump systems, due to the acceleration and deceleration of the liquid in the suction piping of these types of pumps. | Comments | Active | |

| 173 | Stoke is unit of | Absolute viscosity | Rate of strain | Kinematic viscosity | Velocity gradient | c | Stoke is the unit of kinematic viscosity and poise is the unit of dynamic viscosity in terms of cgs. | Comments | Active | |

| 174 | The depth of fluid is measured in vertical Z-direction; X and Y are the other two directions and are mutually perpendicular. The static pressure variation in the fluid is given by | dp/dz = g | dp/dz = \(Ï\) | dp/dz = \(Ïg\) | dp/dz = \(-Ïg\) | d | The pressure at any point in a fluid at rest is obtained by the Hydrostatic Law, which states that the rate of increase of pressure in a vertically downward direction must be equal to the specific weight of the fluid at that point. p = Ïgh Pressure distribution profile dp/dz = -ω = -pg dp = -ω.dz It indicates that a negative pressure gradient exists upward along any vertical. |

Comments | Active | |

| 175 | Stability of a freely falling object is assured if its | Centre of buoyancy lies below its centre of gravity | Centre of gravity coincides with its centre of buoyancy | Centre of gravity lies below its meta centre | Centre of buoyancy lies below its meta centre | c | Stability of body is governed by the metacentre of the floating body. For stable body: Metacentre lies above its C.G. For unstable body: Metacentre lies below its C.G. For Neutral body: Metacentre lies on its C.G |

Comments | Active | |

| 176 | The Euler’s equation of motion is a statement of | Energy balance | Conservation of momentum for an incompressible flow | Conservation of momentum for a real fluid | b | The Euler's equation for a steady flow of an ideal fluid along a streamline is a relation between the velocity, pressure and density of a moving fluid It is based on the Newton's Second Law of Motion which states that if the external force is zero, linear momentum is conserved. | Comments | Active | ||

| 177 | Loss of head due to sudden expansion of flow stream in a closed conduit is expressed by | \((V12-V22)\) | \((V_{1}-V_{2})^{2}/2g\) | \((V_{1}+V_{2})^{2}/2g\) | \((V_{1}-V_{2})/2g\) | b | Losses due to: Sudden Expansion \(h_{Exp}=\frac{(v_{1}-v_{2})^{2}}{2g }\) Exit Loss \(h_{exit}=\frac{v^{2}}{2g}\) |

Comments | Active | |

| 178 | The Chezy co-efficent C is related to Manning’s roughness co-efficient n as | \(C=nym\frac{1}{6}\) | \(C=\frac{1}{n}ym\frac{1}{6}\) | \(C=nym\frac{1}{3}\) | \(C=nym\frac{1}{2}\) | b | The Chezy co-efficent C is related to Manning’s roughness co-efficient n as: \(C=\frac{1}{n}ym\frac{1}{6}\) Where C = Chezy’s Constant Ym = Hydraulic Radiusn = Manning’s Roughness Coefficient |

Comments | Active | |

| 179 | When a body, floating in a liquid, is given a small angular displacement, it starts oscillating about a point known as | Centre of pressure | Centre of gravity | Centre of buoyancy | Meta centre | d | Meta Centre is defined as the point about which a body starts oscillating when body is tilted by a small angle. The meta-centre may also be defined as the point at which the line of action of the force of buoyancy will meet the normal axis of the body when the body is given a small angular displacement. | Comments | Active | |

| 180 | The metacentric height of a ship is 0.6 m and the radius of gyration is 4 m. The time of rolling of a ship is | 4.1 s | 5.2 s | 10.4 s | 14.1 s | c | Given Radius of gyration (K) = 4mGM = 0.6m Time period = \(2Ï€\frac{K^{2}}{GM.g}\) |

Comments | Active |