| S.No | Question | Option A | Option B | Option C | Option D | Answer | Solution | Comments | Status | Action |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Select the most appropriate alternative about cutting fluids. | It reduces heat generation. | It wash away the chips from metal. | It reduces energy consumption. | All of these | d | Cutting fluids performs several functions and some of them are cool the tool and workpiece.i. Reduce the frictionii. Protect work against rustingiii. Improve the surface finishiv. Prevent the formation of Built-up edges (BUEs)v. Wash away the chips from the cutting zone | Comments | Active | |

| 2 | Helix angle for most of the drills lies from | 10° to 15° | 15° to 20° | 20° to 24° | 24° to 30° | d | Helix angle is the angle between the leading edge of the land and the axis of the drill. It is also known as the spiral angle. The usual range of helix angle used in the drill is 24° to 30°. | Comments | Active | |

| 3 | The tool used in the shaper is a | Multipoint cutting tool | Two point cutting tool | Single point cutting tool | None of these | c | The cutting tool used in a shaper is a single point cutting tool having rake, clearance and other tool angles similar to a lathe tool. |

Comments | Active | |

| 4 | The value of ‘n’ for High Speed Steel (HSS) tool in Taylor’s relation = constant is in the range \(VT^{n} \) | 0.1 to 0.15 | 0.2 to 0.4 | 0.4 to 0.6 | None of these | a | Value of n = 0.1 to 0.2; for H.S.S. tools 0.2 to 0.4; for Carbide tools 0.4 to 0.6; for Ceramic tools |

Comments | Active | |

| 5 | Following type of chip is produced while machining ductile metals with extreme pressure in cutting zone and high local temperature (a) Continuous chip | Continuous chip with built up edge | Discontinuous chip | Discontinuous chip with built up edge | b | Continuous Chip with built up edge is obtained by  machining on ductile material, in this condition of high local temperature and extreme pressure in the cutting and high friction in the tool chip interference, may cause the work material to adhere or weld to the cutting edge of the tool. | Comments | Active | ||

| 6 | The correct sequence of processes for getting smooth surface is as follows: (I – Grinding, II – Honing, III – Burnishing, IV – Buffing) | I → IV → II → III | I → II → III → IV | I → II → IV → III | I → IV → III → II | c | Grinding: Grinding is an abrasive machining process that uses a grinding wheel or grinder as the cutting tool. Grinding is a subset of cutting, as grinding is a true metal-cutting process. Grinding is very common in mineral processing plants and the cement industry. Grinding is used to finish workpieces that must show high surface quality and high accuracy of shape and dimension. | Comments | Active | |

| 7 | For good permeability of moulding sand, the following is not a desirable characteristics: (a) higher percentage of silica | Larger grain size | Lower silt percentage | Sand mixture containing grains of all sizes | d | The permeability decreases, if sand mixture containing grains of all sizes. | Comments | Active | ||

| 8 | Following is not a characteristic of powder metallurgy: | Complex shapes can be produced | Bimetallic and laminated parts can be made | Cost effectiveness | Low production rates due to complex shapes | d | In Powder metallurgy process the production rate is very high. So option d is the correct answer. | Comments | Active | |

| 9 | The following type of welding is used for joining rails and heavy pipes etc : | Laser beam welding | Resistance welding | Ultrasonic welding | Thermit welding | d | Thermit mixture can be heated in a crucible upto 1200 using Mg rod and crackers. At this temperature due to thermit reaction heat will be produced & iron is separated. will be acting as a slag.Thermit reaction \(℃\) \(Al_{2}O_{3}\) \(Fe_{2}O_{3}+2Al →Al_{2}O_{3}+2Fe+∆h\) Application: Repair works of railway rails, Joining of high thickness plates and broken castings. |

Comments | Active | |

| 10 | In gas welding, the following type of flame is used for welding brass, bronze and gold: | Neutral flame | Reducing flame | Oxidising flame | Both neutral and reducing flames | c | Oxidizing Flame: Oxygen to Acetylene ratio is greater than one.Application-Copper, Brass, Zinc, Bronze etc. | Comments | Active | |

| 11 | The tool used for removing nails from wood is | Screw-driver | Chisel | Pincer | None of these | c | Pincer is used for extracting deep embedded nails from timber. Suitable for extracting nails from concrete. | Comments | Active | |

| 12 | Following is natural defect found in timbers: | Pitch | Heart shakes | Medulla | Both (a) and (b) | b | Most common natural defects are:Â knots, shakes, cross grain, crookedness, rind galls, burr, and curl. | Comments | Active | |

| 13 | Welding used for production of high quality butt welds in thicker steel plates is | Resistance welding | Gas welding | Seam welding | Submerged arc welding | d | Submerged ARC welding method is widely used in thick plate welding. It is more efficient than conventional welding process like MIG/SMAW welding. | Comments | Active | |

| 14 | The process of increasing the thickness of a bar at the expense of its length is called | Drawing down | Setting down | Upsetting | None of these | c | A heading tool or ram is positioned perpendicular to the cross sectioned end face of a rod or bar gripped in a die. On application of pressure, the length of the rod is reduced and the diameter is increased (upset). | Comments | Active | |

| 15 | Solid solution of carbon in gamma iron is called | Austenite | Sorbite | Troostite | Ferrite | a | Austenite is a solid solution of carbon in gamma iron. | Comments | Active | |

| 16 | Air washer is a plant used for | Cleaning air | Washing air | Year round air-conditioning | None of these | c | An air washer is a device for conditioning air. In an air washer air comes in direct contact with a spray of water and there will be an exchange of heat and mass (water vapour) between air and water. | Comments | Active | |

| 17 | Wet bulb depression is equal to | WBT – DPT | DPT – WBT | DBT – DPT | DBT – WBT | d | Wet bulb depression is a difference between dry bulb temperature and wet bulb temperature at any point Wet Bulb Depression = DBT-WBT *For a saturated air wet bulb depression is zero. |

Comments | Active | |

| 18 | N.P.S.H. stands for | Net Positive Supply Head | Net Power Supply Head | Net Positive Suction Height | Net Positive Suction Head | d | Net Positive Suction Head | Comments | Active | |

| 19 | In Kaplan turbine, the number of blades is generally | 2 to 4 | 4 to 8 | 8 to 16 | 16 to 24 | b | Kaplan turbine is a complete reaction turbine that works based on the lift force generated on the impeller blades due to its aerofoil shape [29]. The working process of the Kaplan turbine is similar to the propeller-type turbine along with adjustable runner blades so that it can work smoothly at vortices and shocks during partial load conditions | Comments | Active | |

| 20 | Following is an inward mixed flow reaction turbine: | Pelton turbine | Francis turbine | Kaplan turbine | None of these | b | The Francis turbine is a type of water turbine that was developed by James B. Francis. It is an inward flow reaction turbine that combines radial and axial flow concepts. In such turbines, the water enters the wheel at the outer periphery and then flows inwards (i.e. towards the centre of the wheel).Here the runner is surrounded by a guide mechanism. In this turbine, the outer diameter of the runner is the inlet and the inner diameter is the outlet. | Comments | Active | |

| 21 | A turbine is coupled with alternator to generate electricity. If number of pair of poles in alternator are 6 and the frequency of electricity is 50 Hz, what should be the speed of the turbine? | 250 rpm | 500 rpm | 1000 rpm | 3000 rpm | c | Speed = \((N_{s})\) \(\frac{120f}{p}\) = 500 rpm \(N_{s}=\frac{120×50}{12}\) |

Comments | Active | |

| 22 | If jet ratio of a Pelton turbine is 8, the number of buckets will be | 8 | 23 | 19 | 31 | c | Given Jet ratio (m) = 8 No. of buckets = 15 + 0.5 m = 15 + \(0.5×8\) = 19 |

Comments | Active | |

| 23 | A jet of water of 0.002 area moving with a velocity of 15 m/s strikes on a series of blades moving with a velocity of 6 m/s. The force exerted on the blades will be \(m^{2} \) | 0.18 N | 270 N | 27 N | 180 N | b | Given Area (A) = 0.002 m2v = 15 m/su = 6 m/s Forces exerted on the series of blades = \(ÏAv(v-u)\) \(F_{x}=1000×0.002×15(15-6)\) \(F_{x}=270 N\) |

Comments | Active | |

| 24 | Of the various methods of measuring discharge through a pipe line, the one with the least loss of energy and direct reading is by | Venturimeter | Orifice meter | Flow nozzle | Traversing a pitot-static probe | a | Due to its simplicity and dependability, the Venturimeter is among the most common flow meters. With no moving parts or abrupt flow restrictions, the Venturimeter can measure fluid flow rates with a minimal total pressure loss. Orifice meter is cheaper than venturimeter but high losses than venturimeter. | Comments | Active | |

| 25 | Uniform flow in a channel is characterised by | The flow is uniform across the channel. | The total energy remains constant along the channel. | Specific energy remains constant along the channel. | Total energy line either rises or falls depending on Froude number. | c | The flow channel is uniform if depth slope, cross section and velocity remain constant over a given length of channel. | Comments | Active | |

| 26 | If the level of water (H) above the base point of V notch is increased by four times, the discharge through the notch will become | 4 times | 8 times | 16 times | 32 times | d | Discharge through V-notch = \(Q_{act}=C_{d}.\frac{8}{15}tan\frac{α}{2}2gH^{\frac{5}{2}}\) Given in question H’ = 4H \(Q_{act}'âˆ(4H)^{\frac{5}{2}}\) \(Q_{act}'âˆ32 H\) Here we can clearly see that if level of water (H) of V notch is increased by 4 times, then the discharge through the notch will become 32 times. |

Comments | Active | |

| 27 | If velocity of flow through a pipe is doubled, the head loss due to friction becomes | Two times | Four times | Eight times | Half | b | Darcy-Weishbach Equation \(h_{f}=\frac{flv^{2}}{D.2g}=\frac{flQ^{2}}{12D^{5}}\) Where;f = frictional factor = 4 = frictional coefficientL = Length of pipe D = Dia of pipeV = Mean velocity of flow f = friction factor ( 0.02 to 0.04 for metals).hf= head loss due to friction \(f'\) \(f'\) Here we can easily see that if we can double the velocity then the head loss due to friction will be increase by four times. |

Comments | Active | |

| 28 | Bernoulli’s equation can be derived from | Continuity equation | Newton’s law of viscosity | Reynold transport theorem | Euler’s equation | d | Here it is Euler’s equation \(\frac{dP}{Ï}+gdz+vdv=0\) BERNOULLI’S EQUATION FROM EULER’S EQUATION Bernoulli’s Theorem:“ For a steady, ideal flow of an incompressible fluid, the total energy which consists of pressure energy, kinetic energy and datum energy, at any point of the fluid is constantâ€. constant \(\frac{p}{Ïg}+\frac{v^{2}}{2g}+z= \) Here; = pressure energy per unit weight of fluid or pressure head = kinetic energy per unit weight or kinetic headz = potential energy per unit weight or potential head \(\frac{p}{Ïg}\) \(\frac{v^{2}}{2g}\) |

Comments | Active | |

| 29 | The centre of pressure of a plane submerged surface | Should coincide with centroid of surface | Should coincide with centroid of pressure prism | May be above or below centroid | Cannot be above mentioned | d | Centre of Pressure of a plane submerged surface Centre of Pressure i. For inclined surface \(h^{*}=\frac{I_{G}sin^{2}θ}{Ah}+h\) ii. For vertical plate \(h^{*}=\frac{I_{G}}{Ah}+h\) Here we can easily see that will be greater than , hence centre of pressure will be below the centroid of surface . \(h^{*}\) \(h\) |

Comments | Active | |

| 30 | If sensible heat load and latent heat load in a building are in the ratio 3:1, sensible heat factor will be | 0.67 | 0.33 | 0.75 | 0.25 | c | Given Sensible Heat Load (S.H.F) : Latent Heat Load (L.H.L) = 3:1 Sensible Heat Factor (S.H.F) = \(\frac{S.H.L }{S.H.L+L.H.L}=\frac{3}{3+1}=\frac{3}{4}\) S.H.F = 0.75 |

Comments | Active | |

| 31 | In summer air-conditioning, the room is maintained at the following conditions: | 21 °C DBT, 50% RH | 21 °C DBT, 60% RH | 25 °C DBT, 50% RH | 25 °C DBT, 60% RH | d | 25 °C DBT, 60% RH | Comments | Active | |

| 32 | A sample of moist air is at a DBT of 25 °C, WBT of 18 °C and DPT of 13 °C and corresponding saturation pressures of water vapour are 3.0 kPa, 2.0 kPa and 1.5 kPa respectively. What will be the relative humidity of air? | 47% | 50% | 65% | None of these | b | We know that \(Relative humidity,∅=\frac{P_{v}}{P_{v_{s}}}=\frac{1.5}{30}=0.5\) |

Comments | Active | |

| 33 | If ha is enthalpy of dry air, is enthalpy of water vapour and w is specific humidity, the enthalpy of moist air will be \(h_{v}\) | \(h_{a} + h_{v}\) | \( h_{a} +w h_{v}\) | \( h_{v} + wh_{a}\) | \(h_{v} + h_{a}/w\) | b | Humidity ratio/Specific humidity (w): It is a given moist air sample is defined as the ratio of the mass of water vapour (mw) to the mass of dry air (ma) contained in the sample.Enthalpy of moist air = Enthalpy of 1 kg of dry air + Enthalpy of water vapour associated with 1 kg of dry air h = ha + whv |

Comments | Active | |

| 34 | In an ideal vapour absorption system, the absorber pressure is equal to the pressure of | Generator | Condenser | Evaporator | Expansion device | c | Pressure in absorber is same as the pressure in evaporator and pressure in generator is same as the pressure in condenser. | Comments | Active | |

| 35 | Wet compression in vapour compression cycle means | Presence of water in refrigerant vapour during compression | Presence of liquid refrigerant in refrigerant vapour during compression | Compression of liquid refrigerant only | Compression of water only | b | If refrigerant or fluid inside compressor is completely gaseous during compression, then it is called dry compression. If refrigerant or fluid is partially liquid, even minutely, during compression, then it is called wet compression. | Comments | Active | |

| 36 | In which cycle, all the four processes are not reversible? | Carnot cycle | Joule cycle | Vapour compression cycle | None of these | c | The principle of vapour compression refrigeration system is based upon the fact that evaporation causes cooling. Whenever evaporation takes place of a liquid, it gives cooling effect. Compression: Here, compression takes place to raise the temperature and refrigerant pressure. The refrigerant leaves the compressor and enters to the condenser. Condensation: The condenser is essentially a heat exchanger. Heat is transferred from the refrigerant to a flow of water. This water goes to a cooling tower for cooling in the case of water-cooled condensation  Throttling and Expansion: Throttling is a highly irreversible process where a high-pressure fluid is converted into low-pressure by using a throttle valve. Evaporation: At this stage of the Vapor Compression Refrigeration Cycle, the refrigerant is at a lower temperature than its surroundings. Therefore, it evaporates and absorbs latent heat of vaporization. |

Comments | Active | |

| 37 | A reciprocating compressor having 0.20 m bore and 0.25 m stroke runs at 600 rpm. If the actual volume delivered by compressor is 4 /min, its volumetric efficiency will be about \(m^{3}\) | 70% | 75% | 80% | 85% | d | Given Dia of bore = 0.20 mlength of stroke = 0.25 m N = 600 rpm = 4 m3/min \(V_{actual}\) Using relation \(ղ_{vol}=\frac{V_{actual}}{V_{swept}}\) Vswept= (as per question) \(Area×length of stroke×rpm=\frac{π}{4}×d^{2}×L×N\) \(V_{swept}=\frac{π}{4}×0.20^{2}×0.25×600=4.712m^{3}/min\) \(η_{Vol}=\frac{4}{4.712}=0.8488\) \(η_{Vol}=84.88%≈85%\) |

Comments | Active | |

| 38 | An axial flow compressor will have symmetrical blades for a degree of reaction: | Lubrication and cooling | Cleaning, sealing and noise reduction | Efficiency enhancement | Both (a) and (b) | d | Lubricants provide three major functions within your engine: cooling, cleaning and reducing friction. The goal is to protect the engine components against damage from heat, contaminants and metal-to-metal contact. | Comments | Active | |

| 39 | The process of scavenging is related to | Two stroke engine | Four stroke engine | Gas turbine | Compressor | a | The process of admitting air and expelling exhaust gas is known as scavenging. The three main types of scavenging for two stroke engines are cross flow, uniflow and loop flow. | Comments | Active | |

| 40 | The engine part that joins piston and piston rod is called | Piston crown | Piston ring | Crank pin | Gudgeon pin | d | The piston is attached to the connecting rod (or piston rod) by a short hollow tube called a wrist pin, or gudgeon pin. This wrist pin carries the full force of combustion. The piston is not only subject to vertical forces during combustion, but also side forces caused by the continuously changing angle of the connecting rod. | Comments | Active | |

| 41 | In an engine working on Otto cycle, air-fuel mixture is compressed from 400 C.C. to 100 C.C. If γ = 1.5, calculate the thermal efficiency of cycle. | 50% | 55% | 68% | None of these | a | Given \(V_{c}=100 m^{3}\) \(V_{T}=400 m^{3}\) \(V_{s}=300 m^{3}\) \(r=\frac{V_{c}+V_{s}}{V_{c}}\) \(r=\frac{100+300}{100}=\frac{400}{100}=4\) \(η_{th}=1-\frac{1}{r^{γ-1}}=1-\frac{1}{(4)^{1.5-1}}\) \(η_{th}=1-\frac{1}{2}=0.5\) \(η_{th}=50% \) |

Comments | Active | |

| 42 | In a Brayton cycle, the air enters the compressor at 300 K and maximum temperature of cycle is 1200 K. What will be the thermal efficiency of cycle for maximum power output? | 75% | 25% | 50% | None of these | c | Given \(T_{min}=300 K\) \(T_{max}=1200 K\) We know that for maximum work output \(r_{p}=(\frac{T_{max}}{T_{min}})^{\frac{γ}{2(γ-1)}}\) Or \(η_{max}=1-\frac{1}{(r_{p})^{\frac{γ-1}{γ}}}\) \(η_{max}=1-\frac{T_{min}}{T_{max}}\) \(η_{max}=1-\frac{300}{1200}=1-\frac{1}{2}\) \(η_{max}=0.5=50%\) |

Comments | Active | |

| 43 | A boiler mounting used to put-off fire in the furnace when water level in the boiler falls below a safe limit: | Blow off cock | Stop valve | Feed check valve | Fusible plug | d | The plug is made up of tin or leads alloy, which has a low melting point. The function of the fusible plug is to put-off the fire in the furnace of the boiler when the water level falls below an unsafe level and thus avoids the explosion, which may take place due to overheating of the tubes and the shell. It is fitted over the crown of the furnace or the combustion chamber. | Comments | Active | |

| 44 | A pump is defined as a device which converts | Lancashire boiler | Cornish boiler | Cochran boiler | Locomotive boiler | c | Specifications of Cochran Boiler:Evaporating Capacity (3600Kg/hr), Low pressure (15bar), Vertical, Natural circulation, Hemispherical Top, Diameter 2.75m, Height 5.79m, Efficiency 70% | Comments | Active | |

| 45 | The flow rate through a circular pipe is measured by | Pitot tube | Venturimeter | Orifice meter | both (b) and (c) | d | Venturi Meter is mainly used to estimate the rate of flow of liquid through a pipe by decreasing the cross-sectional area and creating a gradient of pressure. An Orifice Meter is basically a type of flow meter used to measure the rate of flow of Liquid or Gas, especially Steam, using the Differential Pressure Measurement principle.The pressure loss in venturi meter is 10% while in the orifice meter the pressure loss is 50-60%. | Comments | Active | |

| 46 | A fly cutter is used on | Lathe | Capstan lathe | Metal spining lathe | Milling machine | d | A fly cutter is a single-point rotary cutting tool primarily used on a milling machine for machining large and flat surfaces. | Comments | Active | |

| 47 | The bottom ring on the piston is known as | Oil ring | Scraper ring | Compression ring | Groove ring | a | The bottom ring is responsible for most of the oil control, helping to make sure the right amount of oil is used to lubricate the working surfaces of the cylinder, while the intermediate ring helps with both functions, playing a finishing role in the combustion sealing as well as the downward oil scraping. | Comments | Active | |

| 48 | The function of a regenerator in a gas turbine is to | Reduce heat loss in exhaust | Permit use of higher compression ratio | Improve thermal efficiency | None of these | c | Function of regenerator in gas turbine i. Turbine work constant.ii. Compressor work constant.iii. Net work constant.iv. Heat input increases. v. Efficiency increases. | Comments | Active | |

| 49 | The chemical formulae for Freon – 12 is | \(CHClF_{2}\) | \(CH_{3}Cl\) | \(CCl_{2}F_{2}\) | None of these | c | Chemical formulae for R-12: Dichlorodifluoromethane (. \(CCl_{2}F_{2})\) | Comments | Active | |

| 50 | The gases used in tungsten inert gas welding are | Helium and neon | Argon and helium | Ozone and neon | None of these | b | An inert shielding gas such as argon, helium or a mixture of both is used to shield the tungsten electrode and the weld pool from oxidation. Hence, the process is also referred to as tungsten inert gas welding. | Comments | Active | |

| 51 | The commonly used material for thermocouples is | Chromel – copper | Chromel – alumel | Platinum – rhodium | Any of these | d | The thermocouple converts temperature to a small DC voltage or current. It consists of two dissimilar metal wires in intimate contact in two or more junctions. The output voltage varies linearly with the temperature difference between the junctions—the higher the temperature difference, the higher the voltage output. | Comments | Active | |

| 52 | The depth of cut depend on the | Cutting speed | Tool material | Rigidity of machine tool | All of these | d | The depth of cut depends on the amount of metal to be removed, tool material, and the power and rigidity of the machine tool. | Comments | Active | |

| 53 | Which of the following is basically a polishing operation? | Soft grinding | Lapping | Honing | Buffing | d | Buffing is defined as a finishing process that involves the use of a loose abrasive on a wheel. To polish a workpiece, a manufacturing company may use a wheel that’s covered with an abrasive disc | Comments | Active | |

| 54 | Electronic components are often joined by | Adhesive | Soldering | Brazing | Welding | b | Soldering is a joining process used to join different types of metals together by melting solder. Solder is a metal alloy usually made of tin and lead which is melted using a hot iron. The iron is heated to temperatures above 600 degrees which then cools to create a strong electrical bond. \(℉\) | Comments | Active | |

| 55 | Cohesiveness of sand depends on | Grain size and shape of sand particles | Bounding material | Moisture content | All of these | d | Properties of moulding sand:CohesivenessThe ability of the sand particles to stick with each other is called cohesiveness. Porosity or Permeability:It is the ability of sand by which it allows the gases to pass through it easily.FlowabilityThe ability of moulding sand to behave like a fluid when it is rammed is called flowability.CollapsibilityThe ability of the moulding sand to collapse after solidification of the molten metal is called collapsibility. | Comments | Active | |

| 56 | Which wood can be used for making patterns? | Mahogany | Pine wood | Teak wood | Any of these | d | Wood is the most popular and commonly used material for pattern making. The main varieties of woods used in pattern-making are shisham, kail, deodar, teak and mahogany. | Comments | Active | |

| 57 | The process of cutting thin gears from metal sheet is known as | Extruding | Stamping | Sintering | Rolling | b | Metal Stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It is a complex process that can include a number of metal forming techniques — blanking, punching, bending and piercing, to name a few. | Comments | Active | |

| 58 | Grey iron is usually welded by | Arc welding (b) Gas welding | TIG (d) MIG | b | Grey cast iron is welded by gas welding. Gray cast iron has low ductility and therefore will not expand or stretch to any considerable extent before breaking or cracking. It has acceptable ductility, tensile strength, yield strength, and impact resistance for most applications. Grey Iron is also excellent in its ability to dampen vibrations making it ideal for machinery bases and as well as many housing applications. | Comments | Active | |||

| 59 | In which type of welding, molten metal is poured for joining the metals? | Arc welding | Thermit welding | MIG | TIG | b | Thermit Welding: 1. Thermit mixture can be heated in a crucible upto 1200 using Mg rod and crackers. 2. At this temperature due to thermit reaction heat will be produced & iron is separated3. will be acting as a slag. Thermit reaction \(℃\) \(Al_{2}O_{3}\) \(Fe_{2}O_{3}+2Al →Al_{2}O_{3}+2Fe+∆h\) Application: Repair works of railway rails,Joining of high thickness plates and broken castings. |

Comments | Active | |

| 60 | Continuous chip may be formed while machining | Brittle material | Hard material | Tough material | Ductile material | d | Favorable conditions for continuous chips are i. Ductile workpiece ii. High speed iii. Low feed rate iv. Low depth of cutting v. High back rake angle. vi. Less friction between tool face and chip |

Comments | Active | |

| 61 | Power required to drive a centrifugal pump is proportional to | Speed (N) | \(N^{2}\) | \( N^{3}\) | \(\frac{1}{N^{2}}\) | c | \((\frac{P}{D^{5}N^{3}})_{m}=(\frac{P}{D^{5}N^{3}})_{P}\) \(D=Outer diameter of impeller\) \(P=Shaft power\) \(H_{m}=Manometric head\) \(N=Impeller speed in rpm\) |

Comments | Active | |

| 62 | Cavitation is caused by | High velocity | Low barometric pressure | High pressure | Low pressure | d | Cavitation:- If a pressure on a pipe goes below or equal to vapor pressure of liquid, then boiling will starts and the bubble get collapse on pipe surface due to which pipe surface will start eroding and cavity will form. It is due to lower suction pressure. | Comments | Active | |

| 63 | Capillary action is due to the | Viscosity of liquid | Cohesion of liquid particles | Surface tension | None of these | c | Capillary action occurs due to cohesive force between liquid particles. | Comments | Active | |

| 64 | The boundary layer on a flat plate is called laminar boundary layer if | Re is less than 2000 | Re is less than 4000 | Re is less than \(5×10^{5}\) | None of these | c | For Flat plate Laminar – Re 5 105 \(≤\) \(×\) Transitional –5 105< Re < 5 105 \(×\) \(×\) Turbulent – Re > 5 105 \(×\) |

Comments | Active | |

| 65 | A simple pitot tube is used to measure | Pressure in a static fluid | Velocity in a flowing stream | Total pressure | Dynamic pressure | b | Pitot Tube is a device used for calculating the velocity of flow at any point in a pipe or a channel. | Comments | Active | |

| 66 | Dry ice is | Free from water | Free from dissolved air or gases | Does not contain impurities | Solidified form of carbon dioxide | d | Dry ice is solid carbon dioxide used in packing frozen items. | Comments | Active | |

| 67 | Range of high pressure boilers are | Below 80 bar | Above 80 bar | 40 to 80 bar | 60 to 80 bar | b | In all modern power plants, high-pressure boilers (> 80 bar) are used widely. | Comments | Active | |

| 68 | Babcock & Wilcox boiler is | Water tube type | Fire tube type | Both (a) and (b) | None of these | a | Babcock And Wilcox Boiler is a stationary water tube boiler. It consists of the steam-water drum. a short tube connects the steam water drum with the uptake header and down header. Specifications of Babcock-Wilcox boilerHorizontal water drum, Low pressure (11.5-17.5bar), Evaporating capacity(20K-40K kg/hr), Natural circulation, Stationary, Inclined (5-15edge) Steel tube (Zigzag), Brick work, Efficiency=60-80%, Size of water tubes= 6cm to 9cm, Dia of drum=1.2m to 1.8m ,Length of drum=6m to 9m |

Comments | Active | |

| 69 | Boiler mountings are necessary for | Operation and safety of a boiler | Increase the efficiency of boiler | Both (a) and (b) | None of these | a | Boiler mountings are safety device installed for the safe operation of a boiler. ... These equipment save the boiler from damage due to extreme pressure, steam back flow, shell collapse due to vacuum, unregulated steam pressure, low water level, back flow of feed water to the pump and dry running respectively. | Comments | Active | |

| 70 | For Parson’s reaction steam turbine, degree of reaction is | 75% | 100% | 50% | 60% | c | Reaction Turbine (Parson Turbine)In a reaction turbine there are fixed and moving blade, here fixed blade act as a nozzle which decrease the pressure and kinetic energy. It’s degree of reaction is 0.5. | Comments | Active | |

| 71 | Steam turbines are governed by the following methods: | Throttle governing | Nozzle control governing | By-pass governing | All of these | d | The methods used for governing the steam turbines are: 1. Throttle Governing 2. Nozzle-Control Governing 3. By-Pass Governing’s 4. Extraction Pressure Regulating System 5. Over-Speed Tripping System/Emergency Governor | Comments | Active | |

| 72 | Two stroke engines have | 8 to 10 | 10 to 15 | 16 to 20 | None of these | c | Cycles Compression Ratior (Range of r) Otto cycle 9-10 or less than 12 Dual cycle 12 to 16 Diesel cycle 16 to 20 |

Comments | Active | |

| 73 | Continuity equation can take the form | \(A_{1}ν_{1}= Α_{2} ν_{2}\) | \( Ï_{1}Α_{1}= Ï_{2} Α_{2}\) | \(Ï_{1}A_{1}ν_{1} = Ï_{2} Α_{2} ν_{2}\) | None of these | c | From mass conservation \(Ï_{1}A_{1}ν_{1} = Ï_{2}Α_{2}ν_{2}\) |

Comments | Active | |

| 74 | Poise is the unit of | Mass density | Kinematic viscosity | Dynamic viscosity | Velocity gradient | c | Teak wood is known as hardest wood in India. | Comments | Active | |

| 75 | Which is the hardest wood? | Teak | Tun | Shisham | Babul | c | Teak wood is known as hardest wood in India. | Comments | Active | |

| 76 | Seasoning of timber refers to | Removing of moisture | Adding moisture | Cutting in desired shape | Removing curves | a | Seasoning is the process of drying timber to remove the bound moisture contained in walls of the wood cells to produce seasoned timber. | Comments | Active | |

| 77 | A knee is part of the following: | Shaper | Lathe | Milling machine | Slotter | c | The knee is a rigid grey cast iron casting which slides up and down on the vertical ways of the column face. An elevating screw mounted on the base is used to adjust the height of the knee and it also supports the knee. | Comments | Active | |

| 78 | Least shrinkage allowance is provided for the following: | Brass | Aluminium | Cast iron | Lead | c | Shrinkage of different materials Bismuth – Negligible. White metal (Tin) – 5 mm/m. Cast Iron – 10 mm/m. Aluminum – 13 mm/m. Brass – 15 mm/m. Copper – 17 mm/m. Steel – 20 mm/m. Zinc – 24 mm/m |

Comments | Active | |

| 79 | In sand moulding, the middle part of flask is called | Cope | Drag | Cheek | Middle flask | c | The main purpose of the flux is to prepare the metal surfaces for soldering by cleaning and removing any oxides and impurities. Oxides are formed when metal is exposed to air and may prevent the formation of good solder joints. | Comments | Active | |

| 80 | The purpose of using flux in soldering is to | Increase fluidity of solder metal | Prevent oxides formation | Wash away the surplus solder | Lowering the melting temperature of solder | b | The main purpose of the flux is to prepare the metal surfaces for soldering by cleaning and removing any oxides and impurities. Oxides are formed when metal is exposed to air and may prevent the formation of good solder joints. | Comments | Active | |

| 81 | Which of the following is the natural abrasive? | Aluminium | Brass | Copper | Cast iron | d | Cutting speed of different metals \(V_{CI} Comments |

Active

|

|

|

| 82 | The cutting edges of a standard twist drill are called | Cutting lip | Flanks | Flutes | Wedges | a | Drill is made from a round bar of tool material, and has three principles parts: the point, the body and the shank. The drill is held and rotated by its shank. The point comprises the cutting elements while the body guides the drill in the operation. Point: The point is the cone shaped end and it does the cutting. It consists of the following:i. Dead center: It is the sharp edge at the extreme tip of the drill. This should always be the exact center of the drill. ii. Lips: these are the cutting edges of the drill.iii. Heel: It is the portion of the point back from the cutting edge. |

Comments | Active | |

| 83 | Which of the following material is used as binding material for grinding wheels? | Silicon carbide | Sodium silicate | Boron carbide | Aluminium oxide | b | Sodium silicate is used as binding material for grinding wheels. | Comments | Active | |

| 84 | Enlarging of an existing circular hole with a rotating single point tool is called | Boring | drilling | Reaming | internal turning | a | Boring is a machining process uses a specially designed cutting tool like a drill bit to enlarge a hole that is already in the part to improve the accuracy. | Comments | Active | |

| 85 | The size of shaper is specified by | Length of stroke | Size of tool | Ratio of forward to return stroke | Size of table | a | In the Shaper machine a single point cutting tool is rigidly mounted on the tool holder, which is mounted on the ram. The work piece is held rigidly in a vice (or clamped directly on the table).The ram reciprocates and thus cutting tool held in tool holder moves backward and forward on the work piece. The size of a shaper is specified by the maximum length of stroke or cut it can make. In a shaper machine work piece is held stationary and the cutting tool moves back and forth across the work and workpiececuts during forward stroke. | Comments | Active | |

| 86 | In which of the following operation on lathe, spindle speed is minimum? | Knurling | Taper turning | Fine finishing | Thread cutting | d | In threading, spindle speed and threading feed rate are always kept minimum. | Comments | Active | |

| 87 | The main function of cutting fluid is to | Wash away the chips | Provide lubrication | Cool the tool and workpiece | All of these | d | Main purposes of cutting fluids are to cool and lubricate machining region as well as to flush away the chips produced. | Comments | Active | |

| 88 | Sprue in casting refers to | Gate | Runner | Riser | vertical passage | d | Sprue is a connecting passage between pouring basin and runner for molten metal in the tapered form to avoid the aspiration effect so that pressure equally maintained in the column of liquid metal streaming to the mould. | Comments | Active | |

| 89 | Which of the following sands is used to keep away the green sand from sticking to the pattern? | Core sand | Parting sand | Loam sand | Synthetic sand | b | Greensand should not stick to the pattern. Cope and drag boxes should be separated and traced easily. Parting sand helps in these. It is clay free silica sand. It is also used as parting dust. | Comments | Active | |

| 90 | Copper sheets are manufactured by process of | Neutral | Oxidising | Carburising | None of these | a | The neutral flame has a one-to-one ratio of acetylene and oxygen. It obtains additional oxygen from the air and provides complete combustion. | Comments | Active | |

| 91 | Francis turbine is used when the available head of water range in | 0 – 25 m | 60 – 250 m | Above 250 m | Can be used for any head | b | Francis turbine is a medium head turbine and they are used generally for medium head application (60 to 250 m). | Comments | Active | |

| 92 | In centrifugal pump, the liquid enters | At the centre | at the bottom | At the top | from sides | a | A centrifugal pump is a mechanical device designed to move a fluid by means of the transfer of rotational energy from one or more driven rotors, called impellers. Fluid enters the rapidly rotating impeller along its axis and is cast out by centrifugal force along its circumference through the impeller’s vane tips. The action of the impeller increases the fluid’s velocity and pressure and also directs it towards the pump outlet.The pump casing is specially designed to constrict the fluid from the pump inlet, direct it into the impeller and then slow and control the fluid before discharge. Fluid enters the impeller at its axis (the ‘eye’) and exits along the circumference between the vanes. |

Comments | Active | |

| 93 | Notch is a device used for the measurement of | Rate of flow through pipes | Rate of flow through small channel | Velocity through pipes | Velocity through small channels | b | A Notch is a device used for measuring the rate of flow of a liquid through a small channel or a tank. It may be defined as an opening in the side of a tank or vessel such as liquid surface in the tank is below the level of opening. ... The discharge over notch is measured by measuring the head acting over the notch. | Comments | Active | |

| 94 | The vanes of centrifugal pumps are usually | Curved forward | Curved backward | Radial | None of these | b | The vanes of centrifugal pumps are curved backward to prevent overloading of the impeller motor. BLADES \(∅<90^{0} backward vane or blade\) \(∅=90^{0} Radial blade\) \(∅>90^{0} Forward vane\) |

Comments | Active | |

| 95 | Which of the following turbine does not require draft tube? | Kaplan turbine | Pelton turbine | Francis turbine | Propeller turbine | b | Unlike reaction water turbines, Pelton turbines require no draft tube because they operate in a pressure-less environment. These can be horizontally or vertically oriented a draft tube is generally not used since the runner operates under approximately atmospheric pressure and the head represented by the elevation of the unit above tail, water cannot be utilized. | Comments | Active | |

| 96 | The value of velocity ratio for Kaplan turbine is about | 0.5 | 0.9 | 1.5 | 2.0 | d | Velocity ratio is defined as the ratio of tangential velocity of vane tip to. \(2 g H_{net}\) For Pelton turbines, it is in the range of 0.45 to 0.5. For Francis turbine it varies from i.e. 0.6 to 0.9. For Kaplan turbines, it is in the range of 1.4 to 2. |

Comments | Active | |

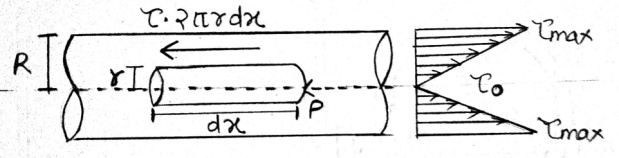

| 97 | The shear stress at a point 5 cm from the pipe axis is 20 Pa. The value of shear stress at the pipe wall, having diameter 20 cm will be | 40 Pa | 80 Pa | 50 Pa | cannot be determined | a | Shear stress distribution for laminar flow \(Ï„=-\frac{r}{2}(\frac{∂P}{∂x})\) So \(Ï„âˆr\) \(\frac{Ï„_{max}}{Ï„}=\frac{R}{r}\) As per given in the question D = 20cm or R=10 cmr = 5 cm \(\frac{Ï„_{max}}{20}=\frac{10}{5}\) \(Ï„_{max}=40 MPa\) |

Comments | Active | |

| 98 | The velocity of liquid flowing through the divergent portion of a venturimeter | Increases | Decreases | Remains constant | Cannot be predicted | b | From continuity equation \(A_{1}×V_{1}=A_{2}×V_{2}\) Or \(Vâˆ\frac{1}{A}\) Since in diverging section area increases. So the velocity will decrease. |

Comments | Active | |

| 99 | The pressure at a depth of 5 km below the surface of the sea water, considering sp. gravity of water to be 1.3, will be | 63765 Pa | 637650 Pa | 1.27 × 108Pa | 1.27 × 109Pa | a | We know that \(Specific gravity, SG=\frac{Ï_{fluid}}{Ï_{standard fluid}}\) \(Ï_{fluid}=Ï_{standard fluid}×SG\) 1.3=1300 kg/m3 \(Ï_{fluid}=1000×\) So \(Pressure, P=Ï_{fluid}gh\) \(P=1300×9.81×5=63765 Pa\) |

Comments | Active | |

| 100 | Falling drops of water become spherical in shape due to the property of | Adhesion | Cohesion | Surface tension | Viscosity | c | Raindrops take up the spherical shape due to the surface tension of water which is caused due to the tendency of water molecules to stick together. The spherical shape is having the least possible surface area due to which it can resist any of the external force in the atmosphere. | Comments | Active | |

| 101 | Bernoulli’s equation refers to conservation of | Mass | Energy | Momentum | None of these | b | Bernoulli's equation expresses conservation of energy for flowing fluids (specifically incompressible fluids), such as water. It shows the equivalence of the overall energy for a given volume of a fluid as it moves Bernoulli’s Theorem: “ For a steady, ideal flow of an incompressible fluid, the total energy which consists of pressure energy, kinetic energy and datum energy, at any point of the fluid is constantâ€. constant \(\frac{p}{Ïg}+\frac{v^{2}}{2g}+z=\) Here; = pressure energy per unit weight of fluid or pressure head \(\frac{p}{Ïg}\) = kinetic energy per unit weight or kinetic head \(\frac{v^{2}}{2g}\) z = potential energy per unit weight or potential head |

Comments | Active | |

| 102 | In conventional refrigerants, which element is responsible for ozone depletion? | Chlorine | Carbon | Hydrogen | Fluorine | a | When chlorine and bromine atoms come into contact with ozone in the stratosphere, they destroy ozone molecules. One chlorine atom can destroy over 100,000 ozone molecules before it is removed from the stratosphere. Ozone can be destroyed more quickly than it is naturally created. | Comments | Active | |

| 103 | A heat pump working on a reversed Carnot cycle has a COP of 4. It is made to work as refrigerator with 1 kW work input. The refrigerating effect will be | 1 | 2 | 3 | 4 | c | Given COP(h.p) = 4 Work input = 1 kW We know that COP (h.p) = 1+ COP(ref) COPref= 1-4 COPref= 3 |

Comments | Active | |

| 104 | In vapour absorption refrigeration, heat is rejected in | Condenser only | Generator only | Absorber only | Both condenser and absorber | d |  |

Comments | Active | |

| 105 | Psychrometer is a device which is used to measure | Dry bulb temperature | Wet bulb temperature | Dry bulb and wet bulb temperature simultaneously | dew-point | c | A psychrometer measures humidity by taking both a wet-bulb and a dry-bulb temperature reading. With those two values known, the other properties of the air, including its moisture content, can be determined by computation or by reading a psychrometric chart. | Comments | Active | |

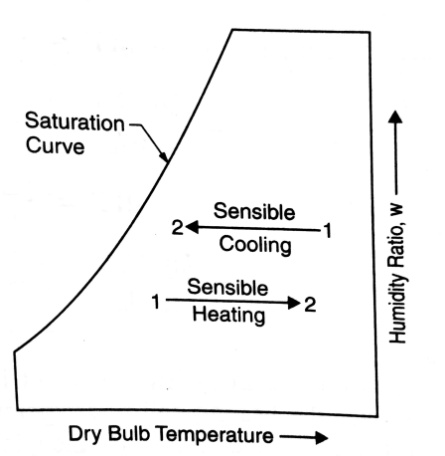

| 106 | Process of sensible heating | Increases specific humidity | Decreases specific humidity | Decreases relative humidity | Increases relative humidity | c | Sensible heating:The heating of air without any change in moisture content. Relative humidity (Specific humidity ( \(∅)=decrease\) \(DBT=Increase\) \(ω)=constant\) |

Comments | Active | |

| 107 | For saturated air, the dew point temperature is | Equal to WBT | less than WBT | more than WBT | None of these | a | It is a temperature on which water vapor just start condensing or it is a saturation temperature which vary with the partial pressure of vapor.When the dew point equals the air temperature, the air is saturated and the relative humidity is 100%. Keypoints For unsaturated air : DBT>WBT>DPT For saturated air : DBT=WBT=DPT |

Comments | Active | |

| 108 | When water – Lithium Bromide is used in a vapour absorption refrigeration system, then | They together act as refrigerant. | Water is the refrigerant. | Lithium bromide is refrigerant. | None of these | b | The lithium bromide absorption refrigeration system uses a solution of lithium bromide in water. Water is being used as refrigerant whereas Li-Br is a highly hydroscopic salt, used as absorbent. The Li-Br solution has a strong affinity for water vapour because of its very low vapour pressure. | Comments | Active | |

| 109 | Household refrigerators operate on | Reversed Carnot cycle | Cascade refrigeration cycle | Vapour absorption cycle | Vapour compression cycle | d | Domestic refrigerator operates on Vapour compression cycle. The vapor compression cycle consists of 'Evaporator', 'Compressor', 'and Condenser ‘and’ Capillary tube' as main parts. The system works on closed cyclic operation with the help of 'refrigerant'. This refrigerant changes the phase during passing through evaporator and condenser to exchange the heat. | Comments | Active | |

| 110 | The throttling operation in a domestic refrigerator is carried out in | Evaporator | Capillary tube | Expansion valve | Condenser | b | Capillary tube is a simple copper tube having very less diameter in few millimeter and longer length in terms of few feet. This low diameter and higher length increase friction and this is the reason why high-pressure liquid refrigerant is converted to low-pressure one due to pressure drop in capillary itself. | Comments | Active | |

| 111 | Most important property of I.C. engine lubricant is | Density | Viscosity | Thermal conductivity | None of these | b | Viscosity is the most important physical property of the oil. It measures the internal resistance of a fluid as one layer moved, in relation to another layer. The oil should be viscous enough to maintain a fluid film between the moving parts or sliding surface or bearing and its journal. | Comments | Active | |

| 112 | Air standard efficiency of an Otto cycle having compression ratio of 5 will be | \(1 – 5^{γ-1}\) | \(1 –\frac{1}{5^{γ-1}} \) | \(1+\frac{1}{5^{γ-1}} \) | None of these | b | Thermal Efficiency or Air standard Efficiency of Otto cycle \(η_{th}=1-(\frac{T_{1}}{T_{2}})\) \(η_{th}=1-\frac{1}{r^{γ-1}}∴\frac{T_{1}}{T_{2}}=\frac{1}{r^{γ-1}}\) Here r = compression ratio. |

Comments | Active | |

| 113 | Higher octane rating for S.I. engine fuel indicates that it has | Higher calorific value | Higher volatility | Higher ignition lag | Lower ignition lag | c | \( Octane numberâˆ\frac{1}{Cetane number}\) And \(Cetane numberâˆ\frac{1}{Ignition delay}\) \(Octane numberâˆIgnition delay\) |

Comments | Active | |

| 114 | Compression ratio in I.C. engine is defined as the ratio of | Total cylinder volume to swept volume | Total cylinder volume to clearance volume | Swept volume to clearance volume | None of the above | b |  Compression ratio of an IC engine is the ratio of total cylinder volume to clearance volume. r = r > 1 \(\frac{V_{1}}{V_{2}}\) \(r= \frac{V_{C}+V_{S}}{V_{C}}\) |

Comments | Active | |

| 115 | The term ‘priming’ in boiler is associated with | Removal of air from the boiler shell | Water particles being carried by steam | Firing of boiler | Control of rate of fuel consumption | b | Priming is the carryover of varying amounts of droplets of water in the steam (foam and mist), which lowers the energy efficiency of the steam and leads to the deposit of salt crystals on the super heaters and in the turbines. | Comments | Active | |

| 116 | In a gas turbine cycle with regeneration | Pressure ratio increases | Work output decreases | Thermal efficiency increases | Heat input increases | c | In the regeneration process, there is reduction in heat supplied to the gas but there is no effect on the turbine and compressor work. Therefore, the regeneration will not increase the work ratio in the turbine but the efficiency of the turbine increases in the regeneration process. | Comments | Active | |

| 117 | If the temperature of intake air in an I.C. engine is lowered, its efficiency will | Increase | Decrease | Remains unchanged | Will increase upto certain limit and then decrease | a | Decreasing the intake air temperature leads to increase in volumetric efficiency due to increase the density of intake air, as a result more air volume draws into the cylinder to the cylinder's swept volume. | Comments | Active | |

| 118 | In magneto ignition system, as the engine speed increases, the value of current | Increases | Decreases | Remains the same | May increase or decrease | a | In the magneto ignition system, engine speed is directly proportional to current rate, so, as the engine speed increases the flow of current increases. The magneto is best at high speeds and therefore is widely used for sports and racing cars, aircraft engines. | Comments | Active | |

| 119 | Chemically correct air-fuel ratio by mass for combustion of petrol is approximately | 5 | 10 | 12 | 15 | d | An ideal fuel/air mixture in which both the fuel and the oxygen in the air are completely consumed is called stoichiometric mixture. Such a mixture doesn’t cause knocking. It is directly dependent on number of hydrogen atoms per a carbon molecule in a fuel. For petrol air fuel ratio by mass is 14.7:1.For CI engines it vary from 18:1 to 80:1 from full load to no load. | Comments | Active | |

| 120 | Thermal efficiency of an ideal diesel cycle | Increases with increase in cut-off ratio | Decreases with increase in cut-off ratio | Does not depend on cut-off ratio | May increase or decrease with increase in cut-off ratio | b | Diesel Cycle 1-2 isentropic compression 2-3 constant pressure heat addition 3-4 isentropic expansion4-1 constant volume heat rejection Compression ratio = \(\frac{V_{1}}{V_{2}}\) Cut off ratio ( \(Ï)\) \(Ï=\frac{V_{3}}{V_{2}}∴Ï>1 \) Efficeincy of diesel cycle \(η_{th}=1-\frac{1}{r^{γ-1}}(\frac{Ï^{r}-1}{(Ï-1)γ})\) Expansion ratio = \(\frac{r}{Ï}\) \(\frac{V_{4}}{V_{3}}=\frac{V_{1}}{V_{3}}\) We can clearly see by the above relation that efficiency of diesel cycle decreases with increase in cut off ratio. |

Comments | Active | |

| 121 | Boiler rating is usually defined in terms of | Maximum temperature of steam | Heat transfer rate kJ/hr | Heating surface area | Heating output in kg/hr | d | Boiler rating is the heating capacity of a steam boiler; it is expressed in BTU per hour (BTU/h), horsepower (hp), or pounds of steam per hour.When a boiler operates at its maximum rated capacity, it is referred to as maximum load. If the load varies from hour to hour, it operates at a varying load. | Comments | Active | |

| 122 | Grate is the place in the boiler where | Fuel is burnt | Pressure of steam is measured | Temperature of saturated steam is increased | None of the above | a | A furnace grate is provided in a steam boiler furnace for supporting the solid fuel in the furnace. Grate is so designed that it can also allow air to admit air in the solid fuel for combustion. | Comments | Active | |

| 123 | Which of the following are continuous products? | Sheets (metallic) | Pipes | Wire rolls | All of these | d | Examples of continuous products:Â Metal Sheets, Pipes, Wire Rolls, Power plant, Chemical plant. | Comments | Active | |

| 124 | Which of the following are discrete products? | Nut | Bolt | Screw | All of these | d | Discrete manufacturing is an industry term for the manufacturing of finished products that are distinct items capable of being easily counted, touched or seen. Discrete manufacturing involves parts and systems like nuts and bolts, brackets, wires, assemblies and individual products. | Comments | Active | |

| 125 | Anvil is made of which of the following metal? | Mild steel | Cast steel | Copper | Brass | b | Anvil is made of cast steel. | Comments | Active | |

| 126 | The cutting tool used in spark erosion machining process is called | Arc | Capacitor | Electrode | Dielectric | c | The cutting tool used in the spark erosion machining process is called Arc. | Comments | Active | |

| 127 | In electro discharge machining the tool is made of | Tungsten carbide | Diamond | Copper or brass | Stainless steel | c | In electro discharge machining the tool is made of cast iron, brass, copper and copper tungsten alloy. The electro discharge machining can machine hardest materials and produces high degree of surface finish. In EDM process the work piece is connected to Anode and the electrode connected to the cathode. | Comments | Active | |

| 128 | Muntz metal contains copper and zinc in the ratio of | 50 : 50 | 40 : 60 | 60 : 40 | 80 : 20 | c | Muntz metal, also called Yellow Metal, variety of the alloy brass consisting of 60 percent copper and 40 percent zinc. | Comments | Active | |

| 129 | The composition of silver solder is | Silver, copper, zinc | Silver, tin, zinc, nickel | Silver, nickel | Silver, copper, nickel | a | Silver solder contains: 65% fine silver. 20% copper. 15% zinc. | Comments | Active | |

| 130 | Which of the following metals can be easily drawn into wire? | Tin | Copper | Zinc | Cast iron | b | Copper can be drawn into wire due to its high ductility. | Comments | Active | |

| 131 | No cutting fluid is used while machining which metal? | Mild steel | Carbon steel | Aluminium | Cast iron | d | No cutting fluid is normally used while machining cast iron because of the self-lubricating property of graphite present in cast iron. Lubrication in cast iron is dry or compressed air. | Comments | Active | |

| 132 | In machining process, chips break due to | Plasticity | elasticity | Work hardening | None of these | c | The hot continuous chip becomes hard and brittle at a distance from its origin due to work hardening and cooling. If the running chip does not become enough curled and work hardened, it may not break. In that case the running chip is forced to bend or closely curl so that it breaks into pieces at regular intervals | Comments | Active | |

| 133 | On tool surface, crater wear occurs mainly due to | Abrasion | Diffusion | Oxidation | Adhesion | b | Flank wear is due to work hardening. It occurs at the tool flanks, where it contacts with the finished surface, as a result of abrasion and adhesion wear. The crater wear is mainly due to diffusion and abrasion. For the crater wear the, the temperature is the main culprit and tool diffuses into the chip material and the tool temperature is maximum at some distance from the tooltip. |

Comments | Active | |

| 134 | Tool life is most affected by | Cutting speed | Tool geometry | Feed and depth | None of these | a | The sequence of parameters affecting tool life is: Cutting speed > Feed > Depth of cut |

Comments | Active | |

| 135 | In blanking operation, the angle of shear is provided on | Die | Punch | Both on punch and die | None of these | a | Blanking is a process in which the punch removes a portion of material from the larger piece or a strip of sheet metal. In this process small removed piece is the useful part and the rest is scrap. | Comments | Active | |

| 136 | Lathe bed is usually made of | Structural steel | Stainless steel | Cast iron | Mild steel | c | Cast iron has a very high damping property that’s why it is used for making lathe bed. | Comments | Active | |

| 137 | The ductility of a material after work hardening | Increases | Decreases | Remains unaltered | None of these | b | Work hardening is the strengthening of a metal by plastic deformation. This strengthening occurs because of dislocation movements and dislocation generation within the crystal | Comments | Active | |

| 138 | Which of the following process is used for gear finishing? | Hobbing | Shaping | Milling | Shaving or burnishing | d | Burnishing is the newest method of gear finishing. It is cold working process accomplished by rolling the gear in contact and under pressure with three hardened burnishing gears. | Comments | Active | |

| 139 | Spinning process is carried out by | Hydraulic press | Mechanical press | Lathe | Milling machine | c | Spinning is a sheet metal forming process in which a metal blank is pressed over a rotating chuck or form mandrel with the help pressing tool to obtain axisymmetric hollow shell any heavy duty lathe with adequate speed range can be used for spinning process. However, special spinning machines have also been designed fitted with a ball-bearing centre, a tool rest with movable steel pins and a rotating chuck made of hard wood. | Comments | Active | |

| 140 | If V is volume of metal in casting and A is its surface area, then time of solidification of metal will be proportional to | \(V,\frac{1}{A}\) | V, \(\frac{1}{A^{2}}\) | \(V^{2}\) | V, A | c | The solidification time of a casting is a function of the volume of a casting and its surface area. Chvorinov’s RuleSolidification time = \(k(\frac{V}{A})^{2}\) For Sphere: (where D is diameter of sphere) \(\frac{V}{A}=\frac{D}{6}\) For Cube: (where a is side of cube) \(\frac{V}{A}=\frac{a}{6}\) |

Comments | Active | |

| 141 | The important property of a material in all metal forming processes is | Elasticity | Plasticity | Ductility | Brittleness | b | Forming operations are those in which the shape of a metal piece is changed by plastic deformation; for example, forging, rolling, extrusion, and drawing are common forming techniques. Plasticity is defined as the mechanical property of a material that retains the deformation produced under load permanently. | Comments | Active | |

| 142 | Which of the following brazing joints is strongest? | Butt | Scarf (inclined) | Lap | All are equally strong. | c | Lap joint is the recommended because the area of overlap in this joint is kept large, which makes the joint stronger. | Comments | Active | |

| 143 | Arc stability is better with | AC welding | DC welding | Both AC & DC welding | None of these | b | In DC welding no fluctuation of power occur and polarity is fixed while in AC welding polarity is not fixed. Therefore, arc stability is better with DC welding. | Comments | Active | |

| 144 | In which of the following welding process consumable electrode is used? | TIG | MIG | Thermit | Laser | b | Metal Inert Gas (MIG) welding is an arc welding process1. arc is generated between consumable electrode and workpiece. 2. Electrode is in the form of small diameter wire which is continuously feed by servo mechanism. 3. Weld pool is protected by shielded Inert gas. 4. D.C or A.C supply can be used. Application: Welding of Al, Mg, Cu and its alloys used in automobiles industry, aerospace and spacecraft industries. |

Comments | Active | |

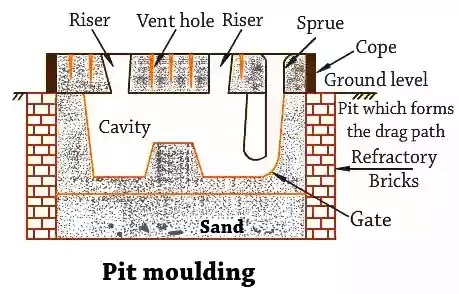

| 145 | Large and heavy castings are made by | Green sand moulding | Pit moulding | Dry sand moulding | Pressure moulding | b | Usually large castings are made in pits instead of drag flasks because of their huge size. In pit molding, the sand under the pattern is rammed by bedding-in process. The walls and the bottom of the pit are usually reinforced with concrete and a layer of coke is laid on the bottom of the pit to enable easy escape of gas. The coke bed is connected to atmosphere through vent pipes which provide an outlet to the gases. One box is generally required to complete the mold, runner, sprue, pouring basin and gates are cut in it. |

Comments | Active | |

| 146 | Hot tear is related to | Casting defect | Process of fabrication | Heat treatment | Welding of non-ferrous metals | a | A hot tear is a discontinuity that occurs during the solidification stage of a casting operation. It can occur because as a material solidifies, it will generally want to contract. | Comments | Active | |

| 147 | Moulding sands are graded according to their | Permeability | Clay content and grain size | Strength | None of these | b | Moulding sand is defined as granular particles resulting from the breakdown of rocks, due to the action of natural forces, such as frost, wind, rain, heat and water currents. Rocks have a complex composition and sand contains most of the elements of the rocks. The principal constituents of moulding sands are as follows: Silica (SiO2)—86 to 90%, Alumina (Al2O3)—4 to 8%, Iron oxide (Fe2O3)—2 to 5% with smaller amounts of the oxides of Ti. MnCa, and some alkaline compounds Moulding sands are graded according to their clay content and grain size Sand is of mainly two types: Natural sand and synthetic sand. | Comments | Active | |

| 148 | The melting point of the filler metal in brazing should be above | 420 °C | 600 °C | 1530 °C | 800 °C | a | Brazing is a joining process traditionally applied to metals (but also to ceramics) in which molten filler metal (the braze alloy) flows into the joint.The melting point of the filler metal is above 450°C, but always below the melting temperature of the parts to be joined. Borax is used as flux in Brazing. | Comments | Active | |

| 149 | If ‘α’ is the angle of blade tip at outlet, then maximum hydraulic efficiency of an impulse turbine is | \(\frac{1 + cos α}{2}\) | \(\frac{1- cos α}{2}\) | \(\frac{1 + sin α}{2}\) | \(\frac{1- sin α}{2}\) | a | Here’s the relation for the hydraulic efficiency of Pelton turbine \(η_{hyd}=\frac{2(V_{1}-u)(1+cos∅)u}{V12}\) Condition of maximum hydraulic efficiency is that blade velocity is half that of the jet velocity. \(u=\frac{V}{2}\) Hence; \(η_{max}=\frac{1+cosα}{2}\) Where vane angle at outlet \( α=\) |

Comments | Active | |

| 150 | Pelton wheels are used for minimum of following heads: | 20 m | 150 m | 25 m | 200 m or above | d | Pelton wheel turbine is generally used for high head and low specific speed. It is a impulse turbine. | Comments | Active | |

| 151 | Friction factor of pipes depends on | Rate of flow | Fluid density | Viscosity | All of these | d | We know that For laminar flow, \(Friction factor, f=\frac{64}{R_{e}}\) Further, \(R_{e}=\frac{Ïvd}{μ}\) Therefore, The friction factor (f) depends on the velocity of flow, fluid density, pipe diameter and the viscosity of the pipe. Roughness of the pipe is also an important criterion to determine the friction factor. |

Comments | Active | |

| 152 | Ratio of inertia force to surface tension is known as | Mach number | Froude number | Reynold’s number | Weber’s number | d | Weber number: It is the ratio of inertia force to surface tension. \(Wb.=\frac{Ï_{g}vg2d_{0}}{σ_{m}}\) |

Comments | Active | |

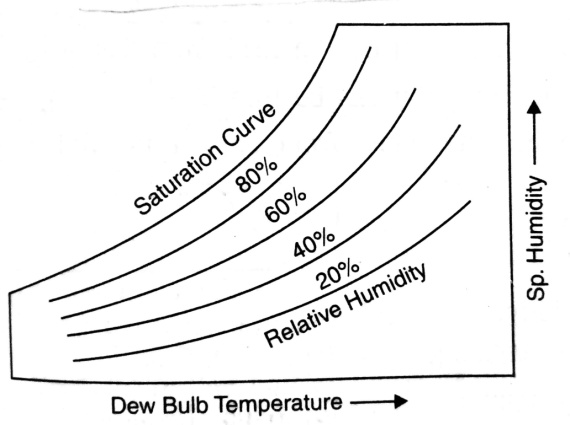

| 153 | The curved lines on a psychrometric chart indicates | Specific humidity | relative humidity | DBT | WBT | b |  |

Comments | Active | |

| 154 | Newton’s law of viscosity is a relationship between | Shear stress and rate of angular distortion | Shear stress and viscosity | Pressure, velocity and viscosity | Shear stress, pressure and rate of angular distortion | a | Newton’s law of viscosity defines, the shear stress between adjacent fluid layers is proportional to the velocity gradient between the two layers. \(Ï„âˆ\frac{dθ}{dt}âˆ\frac{du}{dy}\) |

Comments | Active | |

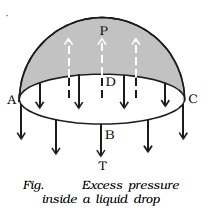

| 155 | The difference of pressure between the inside and outside of a liquid drop is | P = T × r | P = T/r | P = T/2r | P = 2T/r | d |  If T is the surface tension of the liquid, the force due to surface tension acting downward along the circumference of the circle ABCD is T 2πr.At equilibrium, Pπr2 = T 2πr P = 2T/r |

Comments | Active | |

| 156 | Which of the following is the unit of entropy? | J/kg °k | Nm/kg sec | J/kg | Nm/sec | a | S.I unit of entropy is J. K-1 but according to question option (a) is correct. | Comments | Active | |

| 157 | Sensible heat is the heat needed to | Vaporise water into steam and vice versa | Change the temperature of a liquid or vapour | Convert water into steam and super heat it | Measure dew point temperature | b | Sensible heat is the energy required to change the temperature of a substance with no phase change. Latent heat is the energy absorbed by or released from a substance during a phase change from a gas to a liquid or a solid or vice versa. | Comments | Active | |

| 158 | As relative humidity decreases, the dew point will be | Lower than wet bulb temperature | Higher than wet bulb temperature | Equal to wet bulb temperature | None of these | a | As relative humidity decreases, the dew point will be lower than wet bulb temperature. This can be seen in the below diagram |

Comments | Active | |

| 159 | Indication of amount of moisture in air is given by | Dry bulb temperature | Wet bulb temperature | Dew point temperature | Saturation temperature | b | The temperature measured by wick-covered bulb of a thermometer is called wet bulb temperature. It represent the amount of moisture in the air. | Comments | Active | |

| 160 | If is partial pressure of water vapour in air and is saturation pressure of water vapour at same temperature, then relative humidity is equal to \(P_{V}\) \(P_{S}\) | \(P_{V}/P_{S}\) | \(P_{S}/P_{V}\) | \(P_{S}-P_{V}\) | \(P_{V}-P_{S}\) | a | Relative humidity :Relative humidity is the measure of water vapour absorbing capacity. \((∅)\) \(∅=\frac{m_{v}}{m_{s}}=\frac{P_{v}}{P_{s}}\) \(m_{v}=mass of vapour\) \(m_{s}=mass of vapour in saturated condition \) Relative humidity of saturated air will be 100%. \(at same volume and teamperature \) \(P_{v}=partial pressure of vapour\) \(P_{s}=partial pressure of vapour in saturated condition\) |

Comments | Active | |

| 161 | Which of the following refrigerants has lowest freezing point? | Freon – 12 | \(NH_{3}\) | \(CO_{2}\) | Freon-22 | d | Refrigerant no Name Freezing point( \(℃)\) R-12 Dichlorodifluoromethane -157 R-22 Difluoromonochloromethane -160 R-717 Ammonia -77.73 R-744 Carbon-dioxide -56.67 |

Comments | Active | |

| 162 | If a heat pump cycle operates between the condenser temperature of +27 °C and evaporator temperature of – 23 °C, then the Carnot COP will be | 0.2 | 1.2 | 5 | 6 | d | Given T1 = +273 = 300 KT2 = -23 K \(27℃\) \(℃+273=250\) Carnot COP of heat pump COPH.P(carnot) = \(\frac{T_{1}}{T_{1}-T_{2}}=\frac{300}{300-250}=6\) |

Comments | Active | |

| 163 | The refrigerant for a refrigerator should have | High sensible heat | High total heat | High latent heat | Low latent heat | c | Properties of Refrigerant: 1. Refrigerant must have low specific heat and high latent heat. Because high specific heat decreases the refrigerating effect per kg of refrigerant and high latent heat at low temperature increases the refrigerating effect per kg of refrigerant. 2. Saturation pressure should be above or equal to the atmospheric pressure.3. Refrigerant should be chemically stable.4. It should not be non-flammable.5. It should be non-toxic.6. It have good thermal conductivity.7. Eco-friendly. |

Comments | Active | |

| 164 | One ton of refrigeration is equal to | 210 kJ/min | 21 kJ/min | 420 kJ/min | 620 kJ/min | a | In terms of tones of refrigeration amount of refrigerant effect develop by melting of one tonne of ice in 24 hours. One tonnes of refrigeration = 1TR = 14017 kJ/hr 1 TR = 210 kJ/min 1TR = 3.5 kJ/sec or kW |

Comments | Active | |

| 165 | Which of the following cycles uses air as the refrigerant? | Ericsson | Stirling | Carnot | Bell-Coleman | d | Bell-Coleman cycle is used in air refrigeration system and compressed air is selected as the refrigerant in this cycle because air is used as refrigerant is safe and it won't do any harm and no damage to atmosphere. | Comments | Active | |

| 166 | Losses in a centrifugal compressor are due to | Inlet losses | Impeller channel losses | Diffuser losses | All of these | d | Frictional losses: A major portion of the losses is due to fluid friction in stationary and rotating blade passages.Incidence losses: During the off-design conditions, the direction of relative velocity of fluid at inlet does not match with the inlet blade angle and therefore fluid cannot enter the blade passage smoothly by gliding along the blade surface. The loss in energy that takes place because of this is known as incidence loss. This is sometimes referred to as shock losses.Clearance and leakage losses: Certain minimum clearances are necessary between the impeller shaft and the casing and between the outlet periphery of the impeller eye and the casing. |

Comments | Active | |

| 167 | Reciprocating air compressor is best suited for | Large quantity of air at high pressure | Small quantity of air at high pressure | Small quantity of air at low pressure | Large quantity of air at low pressure | b | Reciprocating air compressor is a positive displacement air compressor in which air is sucked in a chamber and compressed with the help of a reciprocating piston. The reciprocating air compressors are found in places where low flow rate and high pressure of the gas are required. | Comments | Active | |

| 168 | What will be the volume of air at 327 °C if its volume at 27 °C is 1.5 ? \(m^{3}\) | 3 \(m^{3}\) | 1.5 \(m^{3}\) | 6 \(m^{3}\) | 10 \(m^{3}\) | a | Here T1= 327 T2 = 27 V2 = 1.5 \(℃=600 K\) \(℃=300 K\) \(m^{3}\) Using Relation \(\frac{V_{1}}{T_{1}}=\frac{V_{2}}{T_{2}}\) \(\frac{V_{1}}{600}=\frac{1.5}{300}\) \(V_{1}=3m^{3}\) |

Comments | Active | |

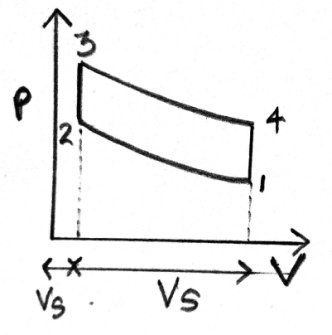

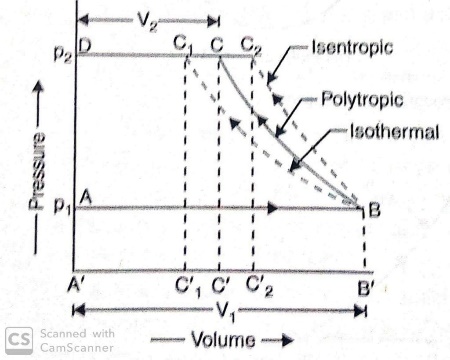

| 169 | Maximum work is done in compressing air when the compression is done in | Isothermal process | Adiabatic process | Polytropic process | None of these | b |  From the figure it is clear that maximum work is done in adiabatic or isentropic process. |

Comments | Active | |

| 170 | In an isothermal process, the internal energy | Increases | Decreases | Remains constant | First increases then decreases | c | Internal energy is the function of temperature, as we know that temperature remains constant during isothermal process. Hence internal energy remains constant during isothermal process. | Comments | Active | |

| 171 | Second law of thermodynamics defines | Entropy | Enthalpy | Heat | Work | a | The second law of thermodynamics states that the total entropy of an isolated system (the thermal energy per unit temperature that is unavailable for doing useful work) can never decrease. \(dS=\frac{δQ}{T}\) |

Comments | Active | |

| 172 | The efficiency of a Carnot engine depends on | Type of fuel | Size of engine | Design of engine | Temperature of source and sink | d | Efficiency of Carnot engine or Reversible engine \(η_{c}=1-\frac{T_{sink}}{T_{source}}\) Efficiency of Carnot engine or Reversible is just depends on the temperature of source and sink. |

Comments | Active | |

| 173 | The relationship between two specific heats and is \(C_{P}\) \(C_{V}\) | / = γ – 1 \(C_{P}\) \(C_{V}\) | - = R/J \(C_{P}\) \(C_{V}\) | - = J/R \(C_{P}\) \(C_{V} \) | + = J \(C_{P}\) \(C_{V}\) | b | Here’s the Mayer’s formula. (For one gm mole of the gas) where = Specific heat at constant volume; Specific heat at constant pressure R = Universal gas constant; Molecular weight of the gas \(C_{P}-C_{V}=R/J\) \(C_{P}\) \(C_{V}=\) \(J=\) |

Comments | Active |