| S.No | Question | Option A | Option B | Option C | Option D | Answer | Solution | Comments | Status | Action |

|---|---|---|---|---|---|---|---|---|---|---|

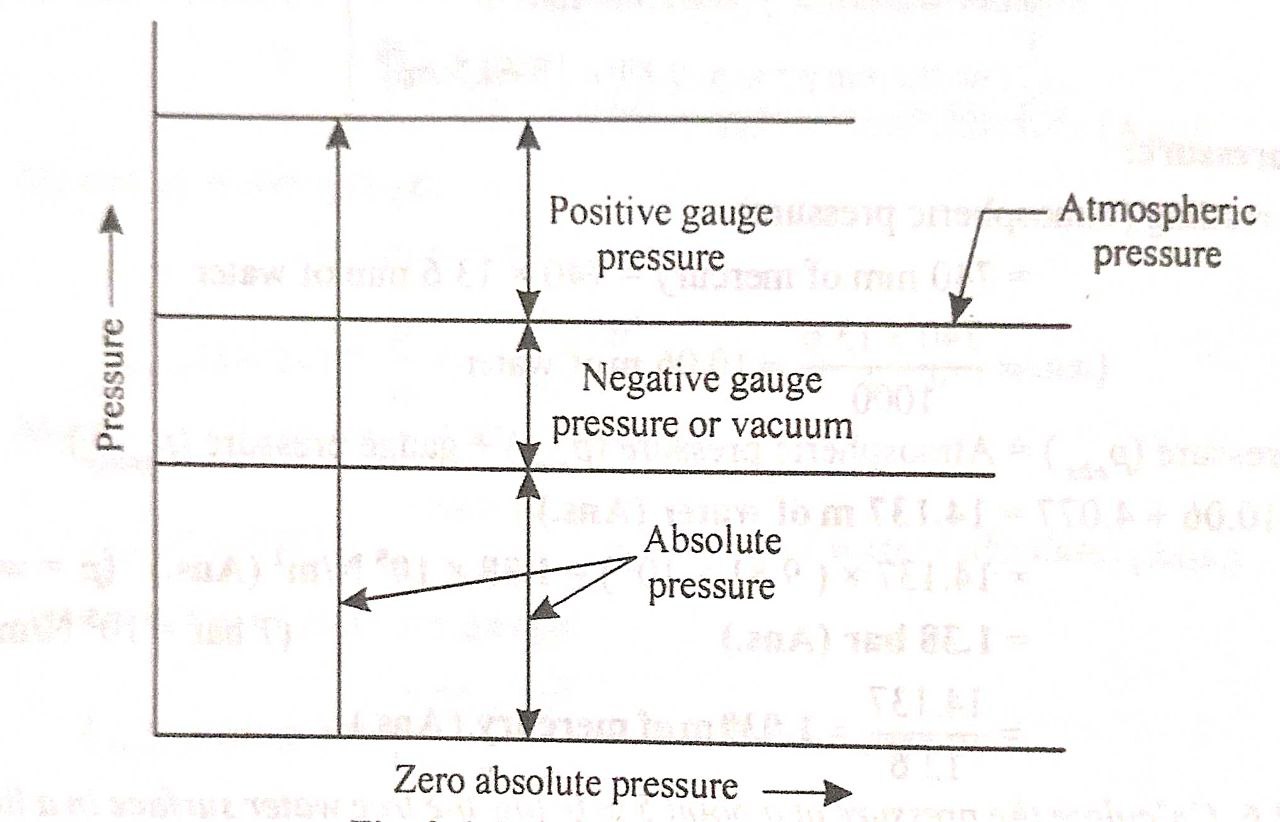

| 1 | The pressure, which is measured with reference to absolute vacuum pressure is called: | absolute pressure | atmospheric pressure | gauge pressure | vacuum pressure | a |  |

Comments | Active | |

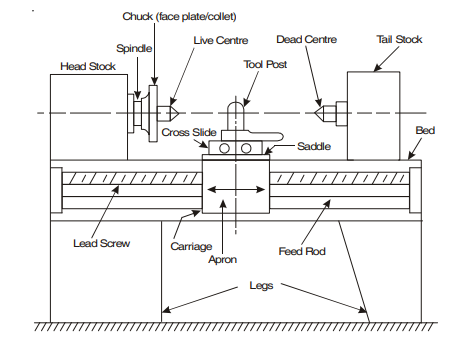

| 2 | Which part of the lathe has a long shaft with the keyway extending from the feed box across and in front of the bed? | Lead screw | Feed rod | Sliding gear shaft | Headstock spindle | b |  |

Comments | Active | |

| 3 | The correct relationship between the coefficient of friction (µ) and the angle of friction: (ɸ) is | µ = tan ɸ | µ = cos ɸ | µ = sin ɸ | µ = cot ɸ | a | Angle of friction: It is defined for every condition (Horizontal plane, Inclined plane etc.) of plane where object placed. Angle of friction () \(tanϕ\) \(tanϕ=\frac{F}{N}=\frac{Friction force}{Normal Reaction}\) * Relation b/w Coefficient of friction and Angle of friction () \((μ)\) \(tanϕ\) \(μ=tanϕ\) |

Comments | Active | |

| 4 | Free expansion process is _________. | an irreversible process | sometimes reversible and sometimes irreversible | initially it is reversible and later it become irreversible | a reversible process | a | Free expansion is highly irreversible possible. For free expaqnsion : dQ =dU = dW = dh = dT=0 |

Comments | Active | |

| 5 | In a single stationary blade type rotary compressor, a blade is set into the slot of a cylinder in such a manner that it always maintains contact with the roller by means of: | cam and follower | spring | gravity | centrifugal force | b | Spring: A spring mechanism provides a constant force that pushes the blade against the roller, ensuring continuous contact regardless of the compressor's orientation or speed. This method is simple, reliable, and effective for maintaining the necessary seal. Thus, in a single stationary blade type rotary compressor, the blade is set into the slot of a cylinder in such a manner that it always maintains contact with the roller by means of a spring. |

Comments | Active | |

| 6 | the boiling point of inorganic refrigerant R-744 is_________. | +22.4°C | +33.6°C | -15.8°C | -73.6°C | d | Refrigerant R-744: Refrigerant R-744 is also known as Carbon Dioxide (CO2). It is an inorganic refrigerant used in various cooling and heating applications. The boiling point of a refrigerant is a critical property that determines its suitability for specific applications. The boiling point of R-744 is significantly lower compared to many organic refrigerants. Let's understand why the boiling point of R-744 is -73.6 . \(℃\) Boiling Point: The boiling point of a substance is the temperature at which it changes from a liquid to a gas at a given pressure (usually atmospheric pressure). For R-744, the boiling point is -73.6, which means it vaporizes at this temperature under standard atmospheric conditions. \(℃\) |

Comments | Active | |

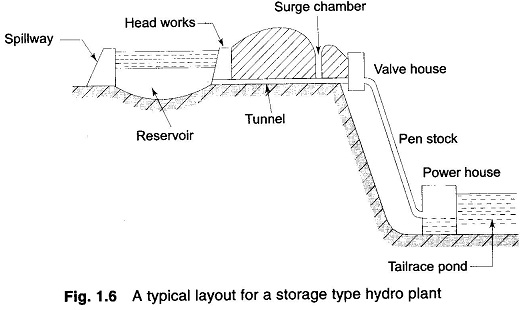

| 7 | Which of the following is NOT a component of a hydroelectric power plant? | Tailrace | Penstock | Surge tank | Condenser | d | from the below layout we can observe that condenser is not the component of hydroelectric power plant. |

Comments | Active | |

| 8 | In an open channel flow, which device increases the enthalpy of gas using external work transfer? | Motor | Turbine | Boiler | Compressor | d | Compressor: A compressor is a device used to increase the pressure of a gas by performing external work on it. The process involves the following: External Work Transfer: A compressor applies mechanical work to the gas. Increase in Enthalpy: As work is done on the gas, its internal energy increases, leading to a rise in temperature and pressure. This results in an increase in the gas's enthalpy (total heat content). |

Comments | Active | |

| 9 | Manometric efficiency of a centrifugal pump is defined as the ______________. | ratio of the actual discharge to the theoretical discharge | difference of the manometric head and the static head | ratio of the power available at the impeller to the power at the shaft | ratio of the manometric head to the head imparted by the impeller | d | Manometric Efficiency: The manometric efficiency of a centrifugal pump is defined as the ratio of the manometric head to the head imparted by the impeller. Manometric head is the actual head against which a centrifugal pump works. To understand this better, let's break down the terms: Manometric Head: It is the total head developed by the pump minus the losses in the pump. It is essentially the head that is effectively used to lift the fluid. Head Imparted by the Impeller: This is the theoretical head that the impeller would impart to the fluid if there were no losses. The formula for manometric efficiency (ηm) is given by: ηm = (Manometric Head) / (Head Imparted by the Impeller) |

Comments | Active | |

| 10 | The bearing surface provided at any position along the shaft (but not at the end of the shaft) to carry the axial thrust, is known as ____________. | conical bearing surface | truncated bearing surface | flat bearing surface | collar | d | Collar: A collar is a bearing surface provided at any position along the shaft (but not at the end of the shaft) to carry the axial thrust. It helps in maintaining the axial position of the shaft and prevents axial movement due to thrust loads. | Comments | Active | |

| 11 | A system undergoes a process in which it absorbs 500 J of heat and does 250 J of work. What is the change in the internal energy of the system? | 250 J | 750 J | −250 J | −750 J | a | To determine the change in the internal energy of the system, we can use the first law of thermodynamics, which is represented as: ΔU = Q - W Where: ΔU is the change in internal energy Q is the heat added to the system W is the work done by the system In this problem, the system absorbs 500 J of heat (Q = 500 J) and does 250 J of work (W = 250 J). Substituting the given values into the first law of thermodynamics equation: ΔU = 500 J - 250 J Calculating the above expression: ΔU = 250 J Therefore, the change in the internal energy of the system is 250 J. |

Comments | Active | |

| 12 | At absolute zero temperature (T = 0K), the specific enthalpy of an ideal gas is: | <0 | infinite | 0 | 1 | c | At absolute zero (0K), the specific enthalpy (h) of an ideal gas is also zero. This is because the internal energy (u) is zero at 0K. The product of pressure (P) and specific volume (v) is also zero at absolute zero because the gas molecules have no kinetic energy and the gas exerts no pressure. |

Comments | Active | |

| 13 | Which of the following is the condition of the maximum discharge of flue gases through a chimney in a steam boiler? | The temperature of flue gases is equal to the atmospheric temperature in Kelvin units. | The maximum discharge of flue gases through a chimney does not depend on the temperature of flue gases in the steam boiler. | The temperature of flue gases is exactly equal to twice the atmospheric temperature in Kelvin units. | The temperature of flue gases is slightly greater than twice the atmospheric temperature in Kelvin units. | d | Chimney and Flue Gases: The primary purpose of a chimney in a steam boiler is to discharge flue gases to the atmosphere. Flue gases are the by-products of combustion and need to be efficiently expelled to ensure the boiler operates safely and efficiently. The discharge of flue gases through a chimney is influenced by various factors, including the temperature difference between the flue gases and the atmospheric air. Maximum Discharge Condition: The maximum discharge of flue gases through a chimney is achieved when the buoyancy effect is maximized. The buoyancy effect is directly related to the temperature difference between the flue gases and the atmospheric air. When the temperature of the flue gases is slightly greater than twice the atmospheric temperature (in Kelvin units), it creates an optimal condition for maximum discharge. This is because a higher temperature difference results in a greater density difference, which in turn enhances the buoyancy effect, leading to a higher discharge rate of flue gases. |

Comments | Active | |

| 14 | if ‘u’ is the velocity of the runner and ‘V’ is the velocity of the jet at inlet, what is the condition for the maximum hydraulic efficiency of a Pelton wheel? | V = 3u | V = 2u | V = u | V = u/2 | b | Hydraulic efficiency: = \(η_{h}\) \(\frac{W.D}{K.E}= \frac{ÏQ(V-u)(1+cosÏ•)u}{\frac{1}{2}ÏaV^{3}}\) = \(η_{h}\) \(\frac{2(V-u)(1+cosÏ•)u}{V^{3}}\) The efficiency will be maximum for a given value of Vâ‚ when \(\frac{d}{d_{u}}(η_{n})=0 ⇒u=\frac{V}{2}\) i.e V = 2u i.e. Hydraulic efficiency of a Pelton wheel will be maximum when the velocity of the wheel is half the velocity of the jet of water at inlet. |

Comments | Active | |

| 15 | The data for an impulse steam turbine are given as follows. (i) Mean blade velocity = 400 m/s (ii) Absolute velocity of steam at the inlet to the moving blade = 1200 m/s (iii) Sum of velocities of whirl at the inlet and the outlet of the blade = 1500 m/s What will be the efficiency of the blade? |

0.67 | 0.83 | 0.5 | 0.42 | b | Mean blade velocity, = 400m / s \(V_{b}\) Absolute velocity of steam at the inlet to the moving blade, = 1200m / s \(V_{1 }\) Sum of velocities of whirl at the inlet and the outlet of the blade, + = 1500m / s \(V_{w1}\) \(V_{w2}\) Given that the sum of the whirl velocities is + = 1500m / s and for an impulse turbine, the whirl velocity at the outlet is typically zero, we have: \(V_{w1}\) \( V_{w2}\) \(V_{w2}\) = 1500m / s \(V_{w1}\) Substituting the values into the blade efficiency formula: \(η_{b}= \frac{2×1500×400}{1200^{2}}\) Calculating the numerator: 2 × 1500 × 400 = 1200000 Calculating the denominator: 12002 = 1440000 Now, calculate the efficiency: = \(η_{b}\) \(\frac{1200000}{1440000} \) \(= 5/6 ≈ x 0.83 \) The efficiency of the blade is approximately 0.83. |

Comments | Active | |

| 16 | The pressure at any point in a fluid at rest has the same magnitude in all the directions. This fact is known as _________ . | Newton’s law | Bernoulli’s law | the pressure law | Pascal’s law | d | Pascal's Law: Pascal's law states that the pressure exerted anywhere in a confined incompressible fluid is transmitted equally in all directions throughout the fluid. This principle applies to fluids at rest and is fundamental in understanding fluid mechanics and hydraulics. |

Comments | Active | |

| 17 | Which of the following statements is INCORRECT about the Cochran boiler? | The Cochran boiler is an externally fired boiler. | The Cochran boiler is a multi-tubular boiler. | The Cochran boiler is a vertical boiler. | The Cochran boiler is a natural circulation type boiler. | a | Cochran boiler is a multi-tubular vertical fire tube boiler having numbers of horizontal fire tubes. It is the modification of a simple vertical boiler where the heating surface has been increased by means of numbers of fire tubes. It is actually an internally fired boiler. The furnace is located inside the boiler shell, not outside. |

Comments | Active | |

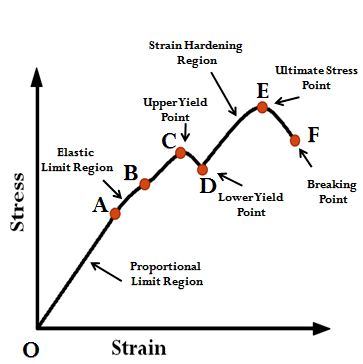

| 18 | Mention the sequence of points that mild steel material undergoes failure by referring to the stress strain diagram. | Elastic Deformation, Strain Hardening, Yielding, Necking, Fracture | Elastic Deformation, Yielding, Strain Hardening, Necking, Fracture | Yielding, Elastic Deformation, Strain Hardening, Necking, Fracture | Yielding, Elastic Deformation, Necking, Strain Hardening, Fracture | b | Elastic Deformation, Yielding, Strain Hardening, Necking, Fracture is the correct sequence. |

Comments | Active | |

| 19 | What is the SI unit of surface tension? | Unitless | \(\frac{N}{m}\) | \(\frac{N}{m^{2}}\) | \(\frac{N}{m^{3}}\) | b | surface tension is force per unit length i.e N/m. | Comments | Active | |

| 20 | The Zenith carburettor is a type of _________. | multijet carburettor | multiple-venturi carburettor | constant-vacuum carburettor | constant-choke carburettor | d | The Zenith carburettor is a type of constant-choke carburettor. Carburettor: A carburettor is a device that mixes air and fuel for internal combustion engines in an appropriate air-fuel ratio for combustion. Types of Carburettors: Constant-vacuum carburettor: It maintains a constant vacuum in the venturi by varying the throttle opening, thus controlling the air-fuel mixture. Multiple-venturi carburettor: It uses more than one venturi to improve the fuel atomization and mixture quality. Constant-choke carburettor: It has a fixed-size choke (venturi) and controls the mixture by varying the fuel flow. The Zenith carburettor falls under this category. Multijet carburettor: It uses multiple jets to supply fuel to the engine, improving fuel distribution and performance. |

Comments | Active | |

| 21 | In which of the following types of draught is air forced into the boiler under pressure by a fan? | Induced draught | Natural draught | Steam jet draught | Forced draught | d | Forced-draught fan: A forced-draught fan, also known as a forced-draft fan or forced-draft blower, is a mechanical device used in steam boilers to ensure a positive flow of air or flue gases into the combustion chamber. This type of fan is positioned at the inlet of the boiler system and is responsible for supplying the necessary air for combustion. Forced-draught (FD) fans are typically centrifugal fans, which means that they use a spinning impeller to accelerate air radially outwards. The impeller is driven by a motor, and the speed of the motor can be controlled to regulate the amount of air that is supplied to the boiler. The power required by a forced-draught fan is lesser than that required by an induced draught fan for the same amount of draught, as they handle fresh air i.e. they suck air |

Comments | Active | |

| 22 | Which of the following statements is INCORRECT about the friction factor of Darcy's equation? | The value of friction factor depends on the Reynolds number of the flow. | The value of friction factor depends on the roughness condition of the pipe surface. | Friction factor is a dimensionless quantity. | Friction factor value is same for all the flow conditions. | d | Darcy's equation is used to calculate the frictional head loss in a pipe due to fluid flow. The friction factor, also known as the Darcy-Weisbach friction factor, is a dimensionless quantity that plays a crucial role in this calculation. Correct Statements about the Friction Factor: 1. Friction factor is a dimensionless quantity: This is correct. The friction factor is derived from the Darcy-Weisbach equation and is used in a dimensionless form to characterize the resistance to flow due to friction in the pipe. 2. The value of the friction factor depends on the Reynolds number of the flow: This is correct. The friction factor varies with the Reynolds number, which indicates whether the flow is laminar or turbulent. For laminar flow, the friction factor is inversely proportional to the Reynolds number. For turbulent flow, the relationship is more complex and can depend on both the Reynolds number and the relative roughness of the pipe surface. 3. The value of the friction factor depends on the roughness condition of the pipe surface: This is correct. In turbulent flow, the friction factor is influenced by the roughness of the pipe's interior surface. Rougher surfaces lead to higher friction factors. |

Comments | Active | |

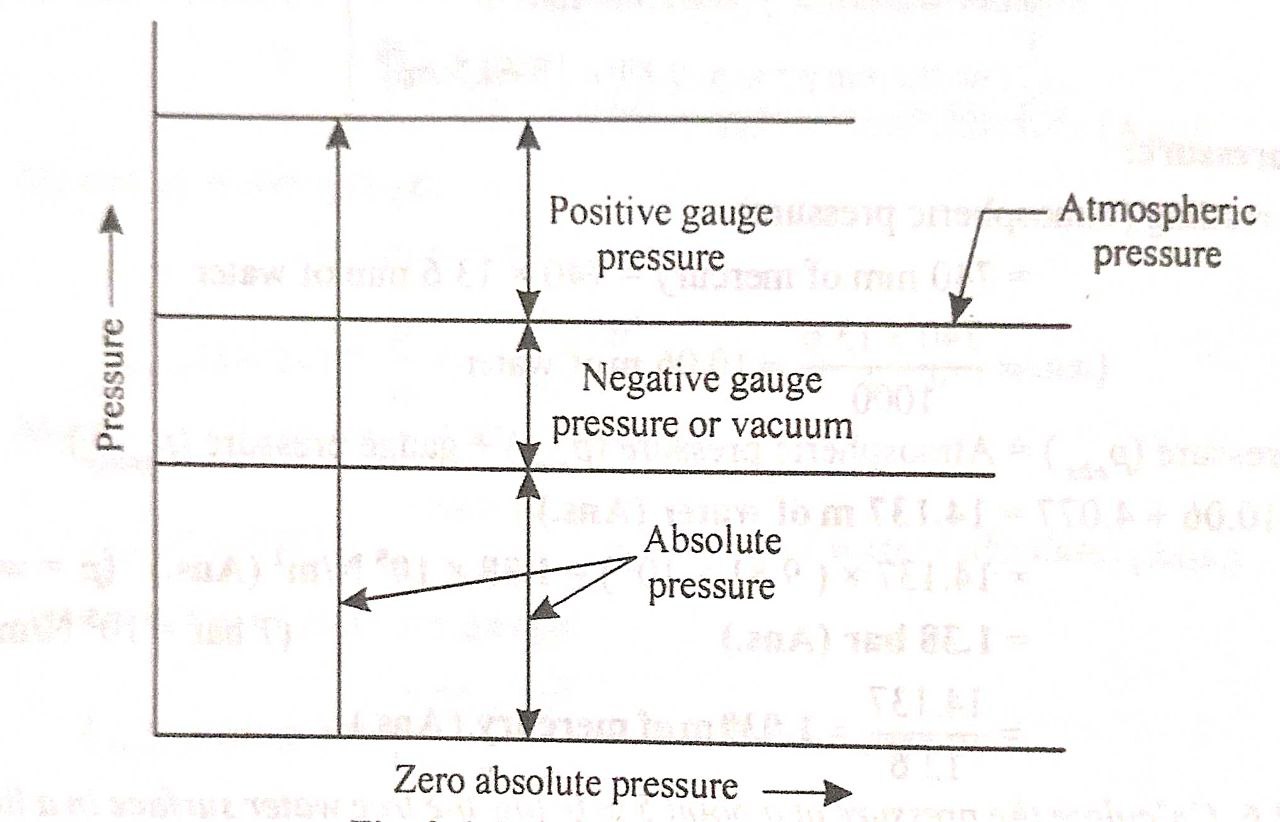

| 23 | Which pressure indicates the difference between the atmospheric pressure and the absolute pressure? | Vacuum pressure | Local atmospheric pressure | Gauge pressure | System pressure | a | Vacuum Pressure: Vacuum pressure is the pressure below atmospheric pressure. It is often measured in terms of the difference from atmospheric pressure. |

Comments | Active | |

| 24 | Under ideal conditions, for a drop of 80 kJ/kg enthalpy, what will be the approximate velocity of steam at the outlet of the nozzle if the inlet velocity of the steam is 2 m/s? | 120 m/s | 410 m/s | 13 m/s | 400 m/s | d | Convert the enthaply drop into compatible units : 1 KJ/KG = 1000m2/s2 \(h_{1}- h_{2}=\frac{80kJ}{kg}=80000m^{2}/s^{2}\) Using the steady flow Energy Equation (SFEE) \(h_{1}- h_{2}= \frac{V^{2}_{2}}{2}- \frac{V^{2}_{1}}{2}\) Substitute the given values: 80000 = \(\frac{V^{2}_{2}}{2}- \frac{2^{2}}{2}\) 80000 = \(\frac{V^{2}_{2}}{2}- 2\) 80000 + 2 = \(\frac{V^{2}_{2}}{2}\) \(V^{2}_{2}=2×80002\) \(V^{2}_{2}= 160004\) \(V_{2} ≈400m/s\) |

Comments | Active | |

| 25 | Sulphur dioxide refrigerant can be designated as: | R-764 | R-744 | R-727 | R-729 | a | If refrigerant is an Inorganic Compound R – (Molecular Weight + 700) The refrigerant designation for Sulphur Dioxide is R-764: The '7' indicates that the refrigerant contains a single sulphur atom. The '64' is derived from the molecular weight of sulphur dioxide. |

Comments | Active | |

| 26 | Which of the following expressions gives the area of flow for a Kaplan turbine? Where, D = diameter, B = width of vane, D0 = outer diameter of runner, Db = diameter of hub | \(Ï€DB \) | \(\frac{Ï€}{4}(D02-Db2)\) | \( \frac{Ï€}{4}(D02)\) | \(Ï€D^{2}B\) | b | Area of Flow in a Kaplan Turbine: The Kaplan turbine is a type of axial flow reaction turbine. The area of flow in a Kaplan turbine is given by the difference in the areas of the outer and inner diameters of the runner. The formula to calculate the area of flow (A) for a Kaplan turbine is: A= \(\frac{Ï€}{4}(D02-Db2)\) Where: D0 = Outer diameter of the runner Db = Diameter of the hub This formula calculates the annular area through which the water flows, considering the outer and inner diameters of the runner. |

Comments | Active | |

| 27 | In case of a flat pivot bearing, which of the following options is correct about the sliding friction? | The sliding friction consideration is along the flat surface of contact between the pivot and the shaft. | The sliding friction consideration is along the length of the shaft which is inside the bearing. | There is no sliding friction between the pivot and the shaft. | The sliding friction consideration is along the vertical curved surface of contact between the pivot and the shaft. | a | Flat Pivot Bearing: A flat pivot bearing is a type of bearing where the load is transmitted through a flat surface of contact between the pivot and the shaft. The primary function of a pivot bearing is to support a rotating shaft and to transmit loads. Sliding Friction in Flat Pivot Bearing: Sliding friction occurs when two surfaces slide against each other. In the case of a flat pivot bearing, the sliding friction is along the flat surface of contact between the pivot and the shaft. This is because the relative motion between the pivot and the shaft occurs along this flat surface. |

Comments | Active | |

| 28 | Which of the following are fire tube boilers? | Benson boilers | Stirling boilers | Scotch-marine boilers | Loeffler boilers | c | Water Tube Boilers: In water tube boilers, water circulates in tubes heated externally by hot gases. These boilers are used for high-pressure applications and larger steam capacities. Examples include Babcock and Wilcox, Stirling, and Benson boilers. Types of Fire Tube Boilers: Simple vertical boiler Lancheshire boiler Cochran boiler Locomotive boiler, Scotch-marine boilers |

Comments | Active | |

| 29 | Which of the following statements is/are correct regarding Fire Tube Boilers? 1) In fire tube boilers, the hot gases are inside the tubes and water surrounds the tubes. 2) Cochran boiler is a type of fire tube boiler. 3) Stirling boiler is a type of fire tube boiler. |

1 and 3 | 2 and 3 | Only 1 | 1 and 2 | d | What is inside that matter if fire is inside the tube then called fire tube boiler and if water is inside the tube then called water tube boiler . Examples include Babcock and Wilcox, Stirling, and Benson boilers are water tube boiler. Fire Tube Boilers: Simple vertical boiler Lancheshire boiler Cochran boiler Locomotive boiler, Scotch-marine boilers |

Comments | Active | |

| 30 | Which of the following statements is INCORRECT about atmospheric pressure? | The atmospheric air exerts normal pressure upon all the surfaces in contact. | The equivalent value of atmospheric pressure is 10.3 cm of water. (c) Atmospheric pressure varies with altitude. | Atmospheric pressure is also called barometric pressure. | b | To determine which statement is incorrect about atmospheric pressure, let's analyze each statement one by one: Option 1: The equivalent value of atmospheric pressure is 10.3 cm of water. This statement is incorrect. The standard atmospheric pressure at sea level is equivalent to approximately 76 cm (or 760 mm) of mercury (Hg). Converting this to water column, it is roughly 1033.6 cm of water, not 10.3 cm of water. Option 2: Atmospheric pressure varies with altitude. This statement is correct. Atmospheric pressure decreases with an increase in altitude because the density of air decreases as altitude increases. Option 3: Atmospheric pressure is also called barometric pressure. This statement is correct. Barometric pressure is another term for atmospheric pressure and is measured using a barometer. Option 4: The atmospheric air exerts normal pressure upon all the surfaces in contact. This statement is correct. Atmospheric pressure acts uniformly in all directions and exerts a perpendicular (normal) force on all surfaces in contact with the air. |

Comments | Active | ||

| 31 | Which of the following materials is commonly used as a cutting tool material? | Diamond | Aluminium | Copper | Brass | a | Cutting tools are essential in manufacturing processes where materials need to be machined into desired shapes and sizes. The choice of cutting tool material significantly affects the efficiency and quality of the machining process. Common Cutting Tool Materials: High-Speed Steel (HSS): Known for its toughness and resistance to wear, HSS is widely used in various machining operations. Cemented Carbides: These are composites of carbide particles bonded with a metallic binder, offering high hardness and wear resistance. Ceramics: Ceramic cutting tools provide excellent heat resistance and are used for high-speed machining. Cubic Boron Nitride (CBN): Known for its hardness second only to diamond, CBN is used for cutting hard materials. Diamond: The hardest known material, diamond is used as a cutting tool material for its exceptional hardness and wear resistance. |

Comments | Active | |

| 32 | _________ is the machining process that uses a saw blade to remove material from a workpiece. | Turning | Filing | Sawing | Drilling | c | Sawing: Sawing is a machining process that involves the use of a saw blade to cut or remove material from a workpiece. The saw blade, which typically has teeth, moves in a linear or circular motion to achieve the cutting action. Sawing is commonly used for cutting materials such as wood, metal, and plastic into desired shapes and sizes. | Comments | Active | |

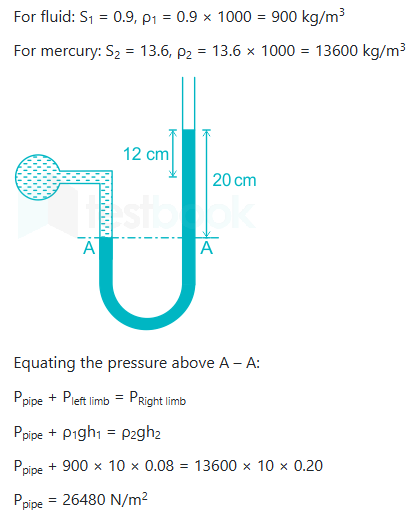

| 33 | The right limb of a simple manometer containing mercury is open to atmosphere. The left limb is connected to a pipe in which a fluid of specific gravity 0.9 is flowing. The centre of the pipe is 12 cm below the level of mercury in the right limb. The difference of mercury level in the two limbs is 20 cm. What is the pressure of fluid in the pipe (take g = 10 m/s2)? | 720 N/m2 | 26480 N/m2 | 27920 N/m2 | 27200 N/m2 | b | For fluid: S1 = 0.9, \(Ï_{1}=0.9×1000=900 kg/m^{3}\) For mercury: S2 = 13.6, \(Ï_{2}=13.6×1000=13600 kg/m^{3}\)  Equating the pressure above A – A \(P_{Pine }+ P_{left limb }= P_{Right limb}\) \(P_{Pine }+ Ï_{1}gh_{1}= Ï_{2}gh_{2}\) \(P_{Pine }+900×10×0.08=13600×10×0.20\) \(P_{Pine }=26480 N/m^{2} \) |

Comments | Active | |

| 34 | The total pressure acting on any immersed body is independent of: | the angle made by surface with the free surface of liquid | the depth of C.G. of body from free surface of liquid | the surface area of body | the density of liquid | a | The total pressure is independent of the angle made by the surface with the free surface of the liquid. Thus, total pressure depends on the following factors: Surface areaof the body Depth of the centroid from the free surface Density of the liquid The total pressure is not influenced by the angle between the surface and the free surface of the liquid. Therefore, the total pressure is independent of the angle made by surface with the free surface of liquid. |

Comments | Active | |

| 35 | Which of the following statements is correct in case of semi-open impeller? | One side of the impeller vanes is covered with a baseplate. | Both sides of the impeller vanes are covered with baseplates. | Both sides of the impeller vanes are covered with crown plates. | Impeller vanes are not covered with baseplates. | a | Semi-open impeller: A semi-open impeller is a type of impeller used in pumps, where one side of the impeller vanes is covered with a baseplate, while the other side remains open. This design allows for easier cleaning and maintenance compared to fully enclosed impellers. Let's understand the different types of impellers for better clarity: Types of Impellers: Closed Impeller: Both sides of the impeller vanes are covered with baseplates. This design provides better efficiency and is used for handling clean liquids. Open Impeller: Impeller vanes are not covered with baseplates. These are used for handling fluids with high solid content. Semi-open Impeller: One side of the impeller vanes is covered with a baseplate. This design is a compromise between the open and closed impellers, providing moderate efficiency and ease of maintenance. |

Comments | Active | |

| 36 | Which of the following is NOT a type of friction? | Kinematic friction | Dynamic friction | Static friction | Kinetic friction | a | Friction: Friction is the resistance to motion of one object moving relative to another. It is not a fundamental force, like gravity or electromagnetism, but arises from the electromagnetic forces between the charged particles in two contacting surfaces. There are different types of friction: Kinetic Friction: Kinetic friction, also known as sliding friction, occurs when two objects are moving relative to each other and rub together (like a sled on the ground). Dynamic Friction: Dynamic friction is another term often used interchangeably with kinetic friction. It refers to the frictional force experienced when two objects are in relative motion. Static Friction: Static friction is the frictional force that prevents two surfaces from sliding past each other. It acts on objects when they are resting on a surface and prevents them from moving. |

Comments | Active | |

| 37 | The ignition coil of an IC engine stores the energy in its _____. | capacitor | resistor | magnetic field | electric field | c | The ignition coil in an internal combustion (IC) engine is a critical component of the ignition system. It is responsible for converting the low voltage from the battery into the high voltage needed to create a spark in the spark plugs, which ignites the air-fuel mixture in the engine's cylinders. Let's understand how the ignition coil works and where it stores energy: Ignition Coil: The ignition coil works on the principle of electromagnetic induction. It consists of two windings: the primary winding (with a few turns of heavy wire) and the secondary winding (with many turns of fine wire). When current flows through the primary winding, it creates a magnetic field around it. When the current is suddenly interrupted, the magnetic field collapses rapidly, inducing a high voltage in the secondary winding |

Comments | Active | |

| 38 | Chezy's equation is applicable for: | transient internal flow | steady open flow | steady internal flow | transient open flow | b | Chezy's Equation: Chezy's equation is used to calculate the velocity of flow in an open channel. The equation is given by: V = C \((RS)\) Where: V = Velocity of flow C = Chezy's coefficient R = Hydraulic radius S = Slope of the energy grade line Steady Flow: In steady flow, the fluid properties at any given point do not change over time. Chezy's equation is specifically applicable to steady flow conditions in open channels. Open Channel Flow: Open channel flow occurs when a liquid flows with a free surface, such as in rivers, canals, and drainage ditches. Chezy's equation is used to determine the velocity of water in these types of channels. |

Comments | Active | |

| 39 | Which of the following moulding techniques uses a sand and clay mixture as the mould material? | Shell moulding | Die casting | Investment casting | Green sand moulding | d | Green sand moulding is a commonly used technique in which a mixture of sand, clay, and water is used to create the mould for casting. The "green" in green sand refers to the fact that the sand mould is not "baked" or dried; it remains moist or "green." Here are the key points for each moulding technique mentioned: Green sand moulding: Uses a mixture of sand, clay, and water. Shell moulding: Uses a resin-covered sand to form the mould. Investment casting: Uses a wax pattern covered with a refractory material to form the mould. Die casting: Uses metal moulds (dies) to cast metal parts under high pressure. |

Comments | Active | |

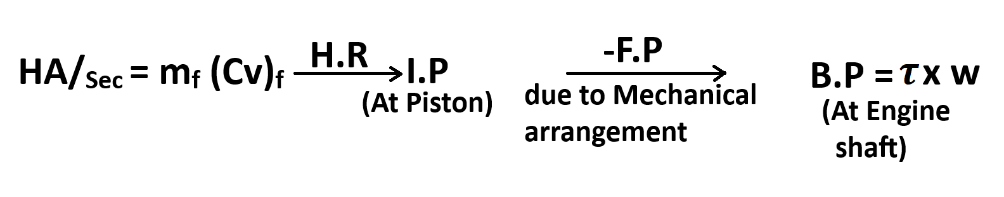

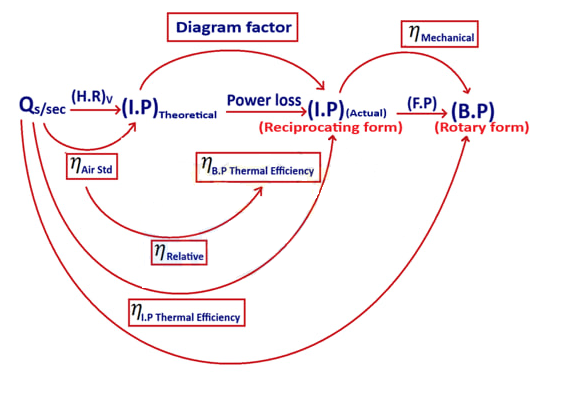

| 40 | If the indicated power and frictional power of an engine are 100 KW and 25 KW, respectively, then what will be the brake power of the engine? | 125 KW | 62.5 KW | 75 KW | 50 KW | c | Given: Indicated Power (IP) = 100 KW Frictional Power (FP) = 25 KW Substituting the given values into the formula: BP = 100 KW - 25 KW BP = 75 KW Therefore, the brake power of the engine is 75 KW. |

Comments | Active | |

| 41 | For which of the following fluids is the rate of deformation proportional to the shear stress? | Rice starch | Gasoline | Blood | Milk | b | Newtonian fluids It is defined as fluids for which the shear stress is linearly proportional to the shear strain rate Newtonian fluids are analogous to elastic solids (Hooke’s law: stress proportional to strain) Any common fluids, such as air and other gases, water, kerosene, gasoline, and other oil based liquids, are Newtonian fluids. | Comments | Active | |

| 42 | Which of the following types of cast iron is the hardest among all? | Gray cast iron | Ductile cast iron | Brittle cast iron | White cast iron | d | Types of Cast Iron: White Cast Iron: This type of cast iron is known for its hardness and brittleness. It is produced by rapidly cooling the molten iron. The rapid cooling prevents the formation of graphite, and instead, carbon remains in the form of iron carbide (cementite), which is extremely hard and brittle. Ductile Cast Iron: Also known as nodular cast iron or spheroidal graphite iron, this type of cast iron has improved ductility due to the presence of spherical graphite nodules. These nodules help in reducing stress concentration points, making the iron more ductile and less brittle. Brittle Cast Iron: This is not a standard term used in metallurgy. It is likely a misnomer or a mixup with other types of cast iron. All cast iron types have varying degrees of brittleness, but this term is not specifically used. Gray Cast Iron: This is the most common type of cast iron, characterized by its gray color due to the presence of graphite flakes. These flakes give gray cast iron its excellent machinability and damping properties, but also make it more brittle compared to ductile cast iron. Among all these types, White Cast Iron is the hardest due to the presence of iron carbide (cementite). However, this hardness comes at the expense of brittleness, making it less ductile and more prone to cracking under stress. |

Comments | Active | |

| 43 | The fully halogenated refrigerants with chlorine (Cl) atom in their molecules are referred to as: | hydro-carbon refrigerants | inorganic refrigerants | HCFC refrigerants | CFC refrigerants | d | Fully halogenated refrigerants with chlorine (Cl) atoms: These refrigerants are part of a group of chemical compounds that are used as refrigerants in various cooling systems and air conditioners. They are known for their high stability and efficiency in heat transfer processes. CFC Refrigerants: CFC stands for Chlorofluorocarbon. These are fully halogenated compounds that contain carbon, chlorine, and fluorine. They were widely used in refrigeration, air conditioning, and as propellants in aerosol sprays due to their chemical stability and non-flammability. Important Points However, CFCs have been found to cause significant damage to the ozone layer, leading to international agreements such as the Montreal Protocol to phase out their production and use. |

Comments | Active | |

| 44 | Which of the following governing methods is used for gas engines? | Quality governing | Controlled governing | Quantity governing | Hit-and-miss governing | d | Hit-and-Miss Governing: Hit-and-miss governing is a type of speed governing method used primarily in gas engines. In this method, the engine is designed to run at a constant speed, and the governor controls the engine speed by allowing or preventing the fuel supply to the engine. This method involves "hitting" (allowing the fuel to ignite) and "missing" (cutting off the fuel supply) cycles based on the speed requirements. Important Points This governing method is highly effective in maintaining the desired speed of gas engines. It is commonly used in small stationary engines, such as those used in agricultural machinery and generators. |

Comments | Active | |

| 45 | Coefficient of discharge (Cd) of a flow-measuring device is defined as the _________ . | product of actual discharge and theoretical discharge | ratio of actual discharge to theoretical discharge | product of cross-sectional area and velocity | ratio of theoretical discharge to actual discharge | b | Co-efficient of Discharge (Cd ) is defined as the ratio of the actual discharge from an orifice to the theoretical discharge from the orifice. By the relation: \(C_{d}= C_{c}× C_{v}\) |

Comments | Active | |

| 46 | Which of the following statements is INCORRECT about the steam separator in a steam boiler? | Steam separator is provided to collect the water resulting from partial condensation of steam. | Steam separator is also known as steam drier. | In the steam separator, steam is made to change its direction of flow. | In the steam separator, water separates out from steam due to its greater inertia. | a | Steam separator is provided to collect the water resulting from partial condensation of steam. It is Incorrect. The primary function of a steam separator is not to collect the water resulting from partial condensation of steam, but to remove the entrained water droplets from the steam to ensure that the steam entering the turbine or engine is dry. | Comments | Active | |

| 47 | When a body is immersed in a fluid, upward force exerted by the fluid is equal to the ________. | volume of water displaced by the body | density of the Body | weight of the fluid displaced by the body | weight of the body | c | When a body is immersed in a fluid, the upward force exerted by the fluid is known as the buoyant force. This phenomenon is explained by Archimedes' principle, which states that: "A body immersed in a fluid experiences a buoyant force equal to the weight of the fluid displaced by the body." |

Comments | Active | |

| 48 | Which of the following assertions holds true when a constant volume of gas is heated? | The work done by the gas is a finite value | The change in enthalpy of the gas is zero | The heat added to the gas is equal to the change in internal energy | The temperature of the gas remains constant | c | When a gas is heated at constant volume, the following thermodynamic principles apply: First Law of Thermodynamics: This law states that the change in the internal energy of a system (ΔU) is equal to the heat added to the system (Q) minus the work done by the system (W). Mathematically, it is expressed as: ΔU = Q - W In a constant volume process, the volume does not change, hence the work done by the gas (W) is zero because work is defined as W = PΔV (where P is pressure and ΔV is the change in volume). Therefore, the equation simplifies to: ΔU = Q Hence, the heat added to the gas is equal to the change in internal energy. |

Comments | Active | |

| 49 | The continuous injection system usually has a _________. | plunger pump | vane pump | gear pump | rotary pump | d | Rotary Pump: A rotary pump moves fluid using the rotation of gears, screws, or vanes. It provides a smooth and continuous flow, making it ideal for continuous injection systems. Vane Pump: It uses vanes mounted on a rotor to pump the fluid. It is often used in power steering and air conditioning systems but is not ideal for continuous fuel injection due to pulsation issues. Plunger Pump: This type of pump uses a reciprocating plunger to move the fluid. It is commonly used in high-pressure applications but can cause pulsation, making it less suitable for continuous fuel injection systems. Gear Pump: Gear pumps use interlocking gears to pump fluid. While they are reliable and efficient, they can also cause pulsation and are generally used in hydraulic systems rather than fuel injection systems. |

Comments | Active | |

| 50 | A quick return motion mechanism used in shaper machine | Complete cutting stroke as quickly as possible | Complete return stroke as quickly as possible | Reduce the motion of the machine | Maximize the time of forward stroke | b | Quick Return Motion Mechanism: A quick return motion mechanism is typically used in shaping, slotting, and planing machines. It is designed to reduce the idle time of the machine by minimizing the time taken for the return stroke. In a shaping machine, the tool moves forward slowly during the cutting stroke to cut the material and returns quickly during the return stroke to save time. Function of Quick Return Mechanism: The primary function is to complete the return stroke as quickly as possible to maximize productivity. This allows more time for the forward cutting stroke, which is where the actual material removal takes place. Important Points The quick return mechanism ensures that the machine's non-productive time is minimized, thereby increasing overall efficiency. MIE – Special point:- In Shaper machine: - Ram drive:- Quick return Motion Mechanism Feed: Ratchet and Pawl mechanism |

Comments | Active | |

| 51 | Calculate the minimum diameter of the shaft, such that the shearing stress does NOT exceed 50 N/mm2 during torque transmission of 15000 N-m. | 98.4 mm | 120.6 mm | 100.2 mm | 115.2 mm | d | Maximum allowable shear stress, = 50N / \(τ\) \(mm^{2}\) Torque transmitted, T = 15000 N - m = 15 × 106 N-mm Step 1: Recall the torsion formula The shear stress in a solid shaft is given by \(τ= \frac{16T}{πd^{3}}\) where d is the diameter of the shaft. Step 2: Rearrange the formula to solve for diameter \(d^{3}=16T/πT\) Step 3: Substitute the given values \(d^{3}= \frac{16×15×10^{6}}{π × 50}=\frac{240×10^{6}}{157.08} ≈1.528×10^{6} mm^{3} \) Step 4: Calculate the diameter d = \(31.528×10^{6} ≈115.2mm\) |

Comments | Active | |

| 52 | Which of the following types of steam nozzle is suitable for use when the inlet steam velocity is very low and the outlet steam velocity is desired to be supersonic? | Divergent-convergent nozzle | Convergent-divergent nozzle | Divergent nozzle | Convergent nozzle | b | Convergent - Divergent nozzles: Convergent - Divergent nozzles are used to increase the flow of gas to supersonic speeds (as in the case of rockets). Their cross-sectional area first decreases and then increases. The area where the diameter is minimum is called the throat. As the gas enters the converging section, its velocity increases, considering the mass flow rate to be constant. As the gas passes through the throat, it attains sonic velocity (Mach number = 1). As the gas passes through the divergent nozzle, the velocity increases to supersonic (Mach number >1) The flow rate is maximum for a given nozzle if the flow is sonic at the throat. This condition is achieved by managing the back pressure. |

Comments | Active | |

| 53 | When a system expands freely against vacuum, then work transfer involved is: | negative | either positive or negative | zero | positive | c | Free Expansion: Free expansion is a process where the system expands into a vacuum without any external pressure opposing the expansion. In this type of expansion, there is no opposing force and hence no work is done by the gas during the expansion. Since there is no external pressure to do work against, the work done is zero. Always remind: in case of free expansion dW=dQ= dE =dh=dT = 0 |

Comments | Active | |

| 54 | Which of the following statements is correct about slotting process? | The tool reciprocates horizontally and the workpiece is fed into the cutting tool. | The workpiece reciprocates horizontally and the tool is fed in. | Both, tool and workpiece can reciprocate according to the size of slotting machine and workpiece. | The tool reciprocates vertically and the workpiece is fed into the cutting tool. | d | The processes of planing, shaping and slotting are similar to one another, but in the first case the main cutting motion is transmitted to the workpiece on the worktable which travels past the cutting tool (except in pit and edge planers where the work is stationary and the cutting tools reciprocate), while in the second and third cases, the workpiece is stationary and the cutting motion is transmitted to the tool. The cutting tool/ workpiece travels horizontally in shaping and planing and vertically in slotting. In all cases, the feed motion is accomplished in a plane perpendicular to the cutting motion (of the workpiece or tool). Feed may be either parallel or perpendicular to the cutting edge, or in a circle. Shaping is limited to small and moderate size workpieces, whereas planers are designed for machining large workpieces. They can take heavy cuts. Cutting is intermittent in all the three processes, since cutting is done in one direction only. The return stroke is idle stroke, and is faster than the cutting stroke. (Reference: A Textbook of production technology by p.c sharma) |

Comments | Active | |

| 55 | In a side milling cutter, the angle between the cleared flank of the blade and a tangent to the periphery in a diametral plane passing through the cutting edge is called ________. | face relief angle | peripheral clearance angle | face clearance angle | peripheral relief angle | b | Peripheral Clearance Angle: The peripheral clearance angle is the angle between the cleared flank of the blade and a tangent to the periphery of the cutter in a diametral plane passing through the cutting edge. This angle is crucial as it helps in reducing the rubbing action of the cutter against the workpiece, thereby minimizing friction and heat generation during the milling process. Importance of Peripheral Clearance Angle: It ensures smooth cutting action by providing adequate clearance between the cutting edge and the workpiece. It helps in reducing tool wear and prolonging the life of the milling cutter. Proper clearance angles also contribute to better surface finish on the machined part. Important Points In a side milling cutter, the angle between the cleared flank of the blade and a tangent to the periphery in a diametral plane passing through the cutting edge is termed as the peripheral clearance angle. This angle is essential for efficient cutting action and reducing tool wear. |

Comments | Active | |

| 56 | ________ is a type of rolling process used in metalworking. | Powder metallurgy | Injection moulding | Hot rolling | Hydroforming | c | Rolling is done both hot and cold. The starting material is cast ingot, which is broken down by hot rolling into blooms, billets and slabs, which are further hot rolled into plate, sheet, rod, bar, pipe, rails or structural shapes. Cold rolling is usually a finishing process in which products made by hot rolling are given a good surface finish and dimensional accuracy with increased mechanical strength of the material. Thinner gauges are obtained by cold rolling. The main objective in rolling is to decrease the thickness of the metal. Ordinarily, there is negligible increase in width, so that the decrease in thickness results in an increase in length. (Reference: A Textbook of production technology by p.c sharma – page no.-221) |

Comments | Active | |

| 57 | The value of specific gravity of mercury is ________. | 13.6 | 1.36 | 0.0012 | 0.136 | a | Specific gravity of mercury =13.6. it means mercury is 13.6 times heavier than water. | Comments | Active | |

| 58 | Which of the following statements is INCORRECT about the high-pressure and lowwater safety alarm in a steam boiler? | The high-pressure and low-water safety alarm has two valves. | The high-pressure and low-water safety alarm is suitable for a locomotive boiler. | The high-pressure and low-water safety alarm operates with loud noise. | The high-pressure and low-water safety alarm is a safety mounting against high pressure and low water levels. | b | The high-pressure and low-water safety alarm is a critical safety feature in steam boilers, designed to alert operators of potentially dangerous conditions. Analysis: 1. The high-pressure and low-water safety alarm is a safety mounting against high pressure and low water levels. This statement is correct. The high-pressure and low-water safety alarm is designed to alert operators of dangerous conditions, such as excessively high pressure or low water levels, which could lead to boiler failure or explosions. 2. The high-pressure and low-water safety alarm is suitable for a locomotive boiler. This statement is incorrect. Locomotive boilers typically have different requirements and safety mechanisms compared to stationary industrial boilers. While some locomotive boilers might have such alarms, it's not universally applicable to all locomotive boilers. 3. The high-pressure and low-water safety alarm operates with loud noise. This statement is correct. Safety alarms in boilers are designed to emit a loud noise to ensure that operators are alerted to the dangerous condition immediately. 4. The high-pressure and low-water safety alarm has two valves. This statement is correct. The high-pressure and low-water safety alarm can have two valves, one for detecting high pressure and another for detecting low water levels. |

Comments | Active | |

| 59 | In the study of flow of fluid in pipes, total energy line is also known as _______________. | pressure line | hydraulic gradient line | energy gradient line | piezometric head line | c | Flow of Fluid in Pipes: In fluid mechanics, the analysis of fluid flow in pipes involves understanding various lines that represent different energy levels in the fluid. Total Energy Line (TEL): The total energy line represents the total energy of the fluid per unit weight at any point in the flow. This total energy includes the elevation head, pressure head, and velocity head. Components of Total Energy: Elevation Head (z): The height of the fluid above a reference level. Pressure Head (p/γ): The height equivalent of the pressure energy of the fluid. Velocity Head (v²/2g): The height equivalent of the kinetic energy of the fluid. The total energy at any point in a fluid flow can be expressed as: Total Energy = Elevation Head + Pressure Head + Velocity Head |

Comments | Active | |

| 60 | Which of the following methods is NOT used for the leakage detection of CFC refrigerants? | Soap solution | Halide torch | Electronic leak detection device | Burning candle | d | Detecting leaks in refrigerant systems, especially those using Chlorofluorocarbons (CFCs), is crucial to ensure the efficiency of the system and prevent environmental damage. Several methods are employed to detect these leaks, each with its own mechanism and application. 1. Burning candle: This method is not used for detecting refrigerant leaks. The use of an open flame near refrigerants is dangerous as it can lead to fire hazards and is ineffective in pinpointing leaks. 2. Soap solution: This is a common method used to detect leaks. A soap solution is applied to the suspected area, and bubbles will form if there is a leak. 3. Halide torch: This method involves using a halide torch. When the flame comes into contact with CFCs, it changes color, indicating the presence of a leak. 4. Electronic leak detection device: These devices are designed to detect refrigerant leaks electronically. They provide a quick and accurate method to identify even small leaks. |

Comments | Active | |

| 61 | Which of the following equations is based on the fact that the mass flow rate at any section remains constant? | Bernoulli’s equation | Momentum equation | Steady flow energy equation | Continuity equation | d | Bernoulli’s equation : conservation of energy Steady flow energy equation : This equation is derived from the first law of thermodynamics and is used to analyze the energy balance in a fluid system. Continuity equation : The continuity equation is a fundamental principle in fluid dynamics that states that the mass flow rate of a fluid must remain constant from one cross-section of a pipe to another, provided the flow is steady and incompressible. Momentum Equation: The momentum equation is derived from Newton's second law and describes the relationship between the forces acting on a fluid and the change in momentum of the fluid. |

Comments | Active | |

| 62 | When there is a ______, work is transferred over the system boundary in an open system. | difference in pressure between the system and surroundings | change in the potential energy of the fluid | change in the kinetic energy of the fluid | difference in datum head between the system and surroundings | a | In thermodynamics, work transfer in an open system is often influenced by various factors. However, the primary factor that leads to work being transferred over the system boundary is a difference in pressure between the system and its surroundings. Open System: An open system is one in which both energy and matter can be exchanged with the surroundings. Examples of open systems include pumps, compressors, and turbines. In the context of an open system, work transfer typically occurs due to pressure differences. Here’s why: Pressure Difference: When there is a difference in pressure between the system and its surroundings, it creates a driving force that can do work. For instance, in a turbine, high-pressure steam enters the system, performs work by rotating the blades, and exits at a lower pressure. |

Comments | Active | |

| 63 | The enthalpy of an open system _________. | is not a meaningful concept | increases as energy is added to the system | decreases as energy is added to the system | remains constant | b | Enthalpy of a System in an Open Flow Definition: Enthalpy (h) is a thermodynamic property of a system, defined as the sum of the internal energy (u) and the product of pressure (p) and volume (v). The formula for enthalpy is given by: h = u + pv In the context of an open flow system, the term pv represents the flow work. Flow Work: Flow work (also known as flow energy) is the work required to push a fluid into or out of a control volume. It is the energy needed to displace the fluid and maintain a continuous flow. The product of pressure and volume (pv) quantifies this work. In an open flow system, flow work is a crucial component because it accounts for the energy associated with the fluid movement into and out of the system. Energy addition in an open system: When energy is added to an open system, it often results in an increase in temperature, which in turn increases the internal energy (U). In addition, if the system allows for expansion, the volume (V) can also increase, leading to an increase in the PV term. Therefore, adding energy to an open system typically results in an increase in enthalpy (H), as both internal energy (U) and the product of pressure and volume (PV) can increase. |

Comments | Active | |

| 64 | For a winter air-conditioning system, relative humidity should NOT be more than: | 60% | 90% | 75% | 40% | d | Summer Air Conditioning: For summer air conditioning, the relative humidity should not be less than 60%. Winter Air Conditioning: For winter air conditioning, the relative humidity should not be more than 40% |

Comments | Active | |

| 65 | The product of the area of the surface and the intensity of pressure at the centroid of the area is called ______. | viscous force | buoyant force | pressure density | total pressure | d | The Viscous force is the force that developed due to the resistance of fluid flow. The pressure force is the product of pressure intensity (N/m) and Cross-sectional area(m ). The Elastic force is the product of elastic stress and the area of fluid. The Gravity force is determined by Newton's gravitation law and is defined as the product of mass and acceleration due to fluid gravity. |

Comments | Active | |

| 66 | The area under a P-V diagram represents _________. | the heat added to the system | the efficiency of the system | the heat rejected by the system | the net work done by the system | d | Area under P-V diagram :- net work done Area Under T-S diagram :- Heat |

Comments | Active | |

| 67 | In chemical machining, material is removed from the work piece by ___________. | chemical evaporation | erosion | chemical burning | chemical dissolution | d | Chemical Machining (CHM): Chemical machining is a non-traditional machining process where material is removed from a workpiece through the use of chemical dissolution. The process involves the controlled removal of material by immersing the workpiece in a chemical solution known as an etchant. The areas of the workpiece that need to be protected from the etchant are masked using a resistant material, leaving only the desired areas exposed for machining. Steps involved in Chemical Machining: Cleaning: The workpiece is cleaned to remove any contaminants that could affect the machining process. Masking: The areas that do not need to be machined are covered with a protective maskant. Etching: The masked workpiece is immersed in an etchant solution, which chemically dissolves the exposed areas. Demasking: The maskant is removed after the desired amount of material has been etched away. Finishing: The workpiece is cleaned and finished to remove any residues from the etching process. |

Comments | Active | |

| 68 | Which of the following statements is true for magneto ignition system? | The efficiency of the system improves as the engine speed increases. | It is simpler in construction than coil ignition system. | More frequent maintenance is required compared to coil ignition system. | Its intensity of spark is very good even at low speed. | a | Characteristics of Magneto Ignition System Simplicity in Construction: • The magneto ignition system is typically more complex in construction compared to the coil ignition system. This is because it incorporates both the energy generation and the high-voltage transformation within the same unit. Efficiency Relative to Engine Speed: • The efficiency of the magneto ignition system improves as the engine speed increases. This is because the magneto generates a stronger spark at higher speeds, making it suitable for high-speed applications like sports cars and aircraft engines. Maintenance Requirements: • Magneto ignition systems generally require less frequent maintenance compared to coil ignition systems since they do not rely on an external battery and have fewer electrical connections. This makes them advantageous for applications where reliability and low maintenance are critical. Spark Intensity at Low Speed: • The magneto ignition system tends to produce a weaker spark at low engine speeds. This can lead to starting difficulties, and sometimes a separate battery is needed to assist with starting the engine. |

Comments | Active | |

| 69 | Pump disassembling is NOT necessary in _________. | semi-open impellers | cannot be predicted | open impellers | closed impellers | c | Pump Impellers: Impellers are a crucial component in centrifugal pumps. They are responsible for the movement of fluid through the pump by converting rotational energy from a motor into kinetic energy in the fluid. There are three main types of impellers used in centrifugal pumps: semi-open, closed, and open. Semi-open Impellers: Semi-open impellers have a shroud (or cover) on one side, while the other side is exposed. They are used for applications where the fluid contains some solids or fibrous materials. Closed Impellers: Closed impellers have shrouds on both sides of the vanes, providing a higher efficiency. They are typically used for clear liquids with no suspended solids. Open Impellers: Open impellers have no shrouds, making them easier to clean and maintain. They are ideal for fluids containing larger particles and are less likely to get clogged. |

Comments | Active | |

| 70 | The condition of equilibrium states that a stationary body that is subjected to coplanar forces will be in equilibrium if the algebraic sum of all the _____ and the algebraic sum of _____ of all the external forces about any point in their plane is zero. | internal forces; moment | external forces; moment | external forces; couple | internal forces; couple | b | Conditions of Equilibrium: For a stationary body subjected to coplanar forces to be in equilibrium, two main conditions must be satisfied. The algebraic sum of all the external forces acting on the body must be zero. This ensures that there is no net force causing linear acceleration. The algebraic sum of the moments of all the external forces about any point in their plane must be zero. This ensures that there is no net torque causing rotational acceleration. Mathematical Representation: ΣF = 0 (Sum of all external forces is zero) ΣM = 0 (Sum of all moments of external forces is zero) |

Comments | Active | |

| 71 | According to the second law of thermodynamics, work is said to be __________ and heat is said to be __________. | high-grade energy; low-grade energy | low-grade energy; high-grade energy | high-grade energy; high-grade energy | low-grade energy; low-grade energy | a | Second Law of Thermodynamics: The second law of thermodynamics states that the total entropy of an isolated system can never decrease over time. It also implies that energy transformations are not 100% efficient, and some energy is always lost as heat. High-grade energy: High-grade energy is energy that can be easily converted to work. Examples include electrical energy and mechanical work. This type of energy is highly organized and can be completely converted into other forms of energy with minimal losses. Low-grade energy: Low-grade energy is energy that is difficult to convert into work. Heat energy is an example of low-grade energy. This type of energy is disorganized and cannot be completely converted into other forms of energy without significant losses. Important Points The second law of thermodynamics emphasizes the quality of energy. Work is considered high-grade energy because it can be completely converted into other forms of energy. On the other hand, heat is considered low-grade energy because only a portion of it can be converted into work, with the rest being lost to the surroundings. |

Comments | Active | |

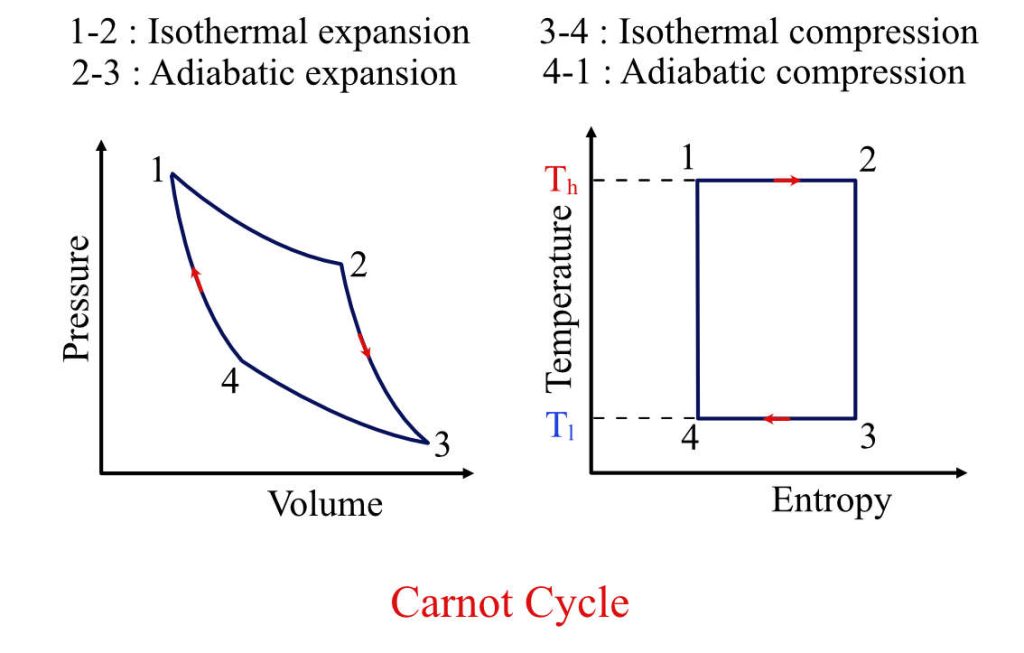

| 72 | Which of the following statements is true about the Carnot cycle? | It involves only two reversible isothermal processes. | It is a reversible cycle. | The efficiency of the Carnot cycle is always less than that of any other heat engine operating between the same two temperatures. | Its efficiency depends only on the pressure difference between the two reservoirs. | b | Carnot cycle: A cycle is said to be reversible only when each process in a cycle is reversible. Carnot cycle consists of 2 isothermal and 2 adiabatic processes. An isothermal process is a very slow process and the adiabatic process is a very fast process and the combination of a slow process and fast process are very difficult. So a Carnot cycle is also known as an impractical cycle. It is used only to compare other actual cycles. Carnot theorem: For different engines operating between the same temperature limit, no engine has an efficiency greater than Carnot cycle efficiency. |

Comments | Active | |

| 73 | For ammonia refrigerating systems, the tubes of a shell and tube condenser are made of_______. | copper | brass | aluminium | steel | d | Ammonia Refrigerating Systems: Ammonia (NH3 ) is commonly used in large-scale refrigeration systems due to its excellent thermodynamic properties and low cost. However, ammonia is also highly reactive with certain metals, which necessitates the use of specific materials in the construction of refrigeration components. Material Selection for Condenser Tubes: The tubes in a shell and tube condenser for ammonia refrigerating systems are typically made of steel. This is because ammonia reacts with copper and its alloys, such as brass, leading to corrosion and potential system failure. Aluminium, while lightweight and thermally conductive, can also react with ammonia under certain conditions, making it less suitable for this application. Important Points: When selecting materials for ammonia refrigerating systems, it is crucial to choose those that are resistant to ammonia corrosion and compatible with its chemical properties. |

Comments | Active | |

| 74 | Which of the following is the chemical formula of hydro-carbon refrigerant R-170? | C3 H6 | C4 H10 | C2 H6 | C3 H3 | c | Saturated Un – saturated Hydrocarbons Representation R – (m – 1) (n + 1) P R – (m – 1) (n + 1) P Chemical formula CmHnFpClq CmHnFpClq Relation n + p + q = 2m + 2 n + p + q = 2m where m = No. of Carbon atoms, n = No. of Hydrogen atoms, p = No. of Florine atoms, q = No. of Chlorine atoms C2 H6 is the correct ans , here m=2, n=6 |

Comments | Active | |

| 75 | Which of the following is a requirement of a good ignition system? | It should have good reproducibility of secondary voltage rise. | It should have very low spark duration. | It should give good performance at low speed but at high-speed, doesn’t matter. | It should be as small as possible in size. | a | Good Reproducibility of Secondary Voltage Rise: This refers to the ability of the ignition system to consistently generate a high-voltage spark required to ignite the air-fuel mixture in the combustion chamber. A good ignition system should reliably produce a strong and consistent spark at the right moment. Analysis: This is a critical requirement because inconsistent voltage can lead to misfires or inefficient combustion, reducing the engine's performance and fuel efficiency. Conclusion: This is an essential feature for a good ignition system. |

Comments | Active | |

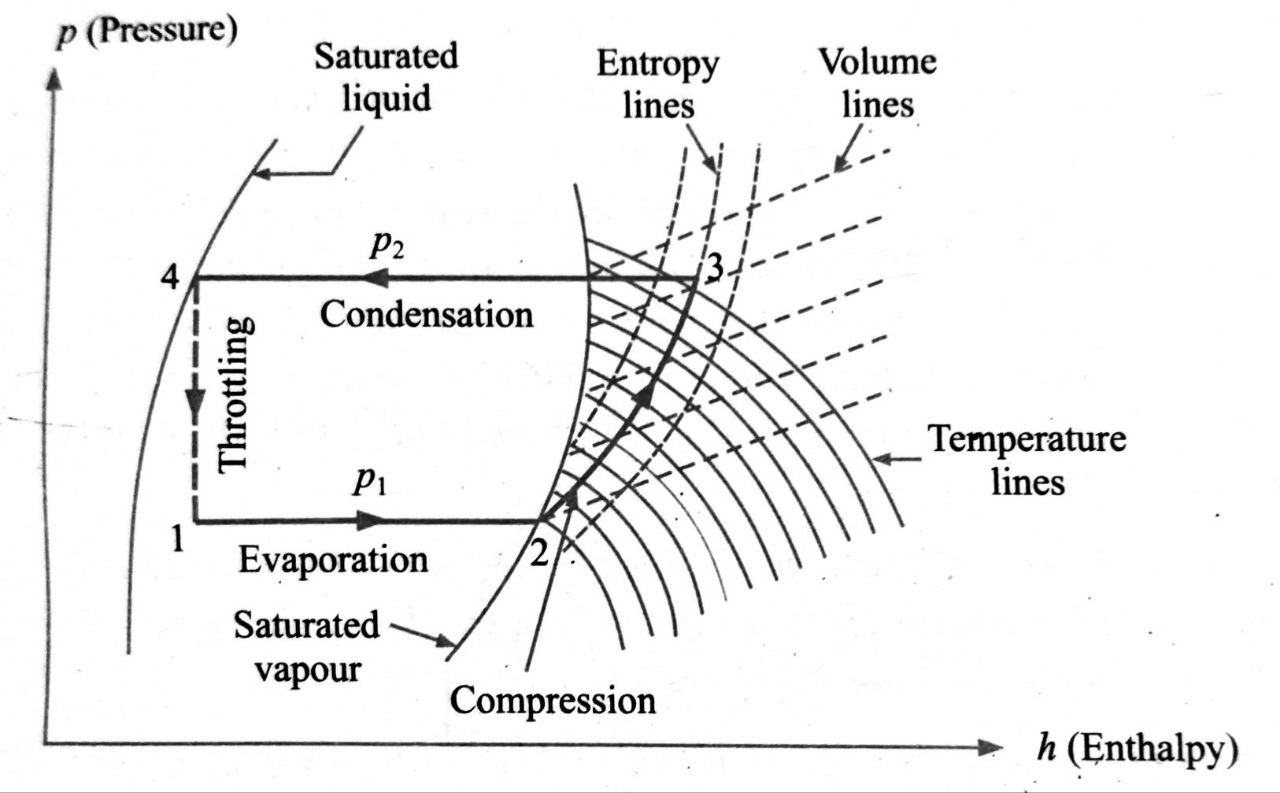

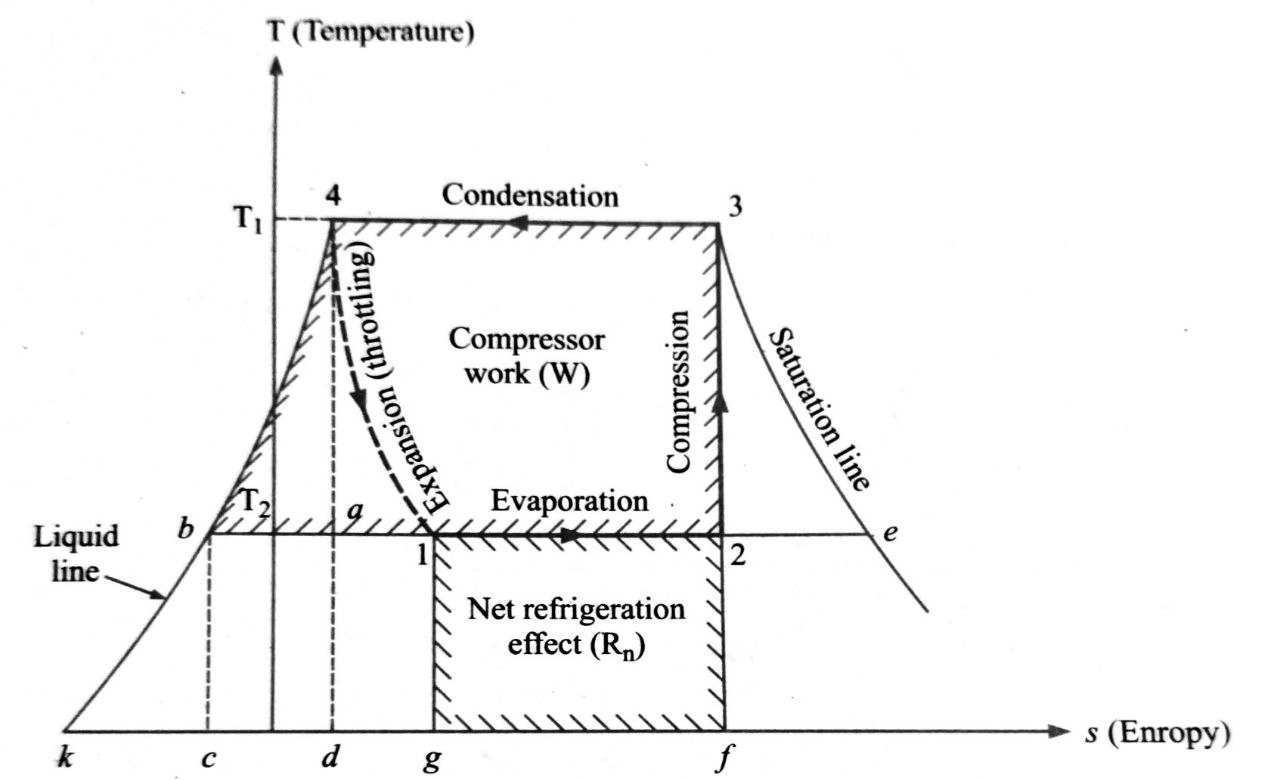

| 76 | In the P-H diagram of the vapour compression cycle, the compression process is shown by a/an _______________. | curved line | inclined straight line with a positive slope | vertical line | inclined straight line with a negative slope | b | Ideally inclined straight line with positive slope but practically it is curved line.so should go with ideal answer till not specified that it is practically. |

Comments | Active | |

| 77 | In a vapour absorption refrigeration system, heating, cooling and refrigeration take place at the temperatures of 100°C, 20°C and -5°C, respectively. Find the maximum C.O.P. of the system. | 1.5 | 2.7 | 1.8 | 2.3 | d | Given:- TR : Refrigeration temperature (in Kelvin) = - 5°C = 268K TA : Absorber/Condenser (cooling) temperature = 20°C = 293K TH : Generator (heating) temperature = 100° C = 373K COP = \(\frac{T_{R}}{T_{H}} . (\frac{T_{H}-T_{A}}{T_{A}-T_{R}})\) COP = \(\frac{268}{373} . (\frac{373-293}{293-268})=0.718 . (\frac{80}{25})=0.718 . 3.2=2.3\) |

Comments | Active | |

| 78 | Vertical depth of any point below the free surface in a liquid at rest is known as _________ . | datum head | total head | pressure head | velocity head | c | Vertical Depth in a Liquid at Rest Definition: The vertical depth of any point below the free surface in a liquid at rest is known as the pressure head. This term is crucial in fluid mechanics and hydraulics, as it helps in understanding how the pressure changes with depth in a fluid at rest. Working Principle: In a liquid at rest, the pressure at any point is due to the weight of the liquid column above that point. This pressure increases linearly with depth because the weight of the liquid above increases. The relationship can be expressed mathematically using the hydrostatic pressure formula: Hydrostatic Pressure Formula: The pressure P at a depth in a liquid of density Ï under the influence of gravity g is given by: P = Ïgh Where: P is the pressure at depth Ï is the density of the liquid g is the acceleration due to gravity h is the vertical depth below the free surface |

Comments | Active | |

| 79 | Internal combustion engines have _____. | high initial cost compared to external combustion engine | lower thermal efficiency than external combustion engine | higher thermal efficiency than external combustion engine | low power to weight ratio compared to external combustion engine | c | IC engines have higher thermal efficiency compared to external combustion engines. This is because the heat generated in an IC engine is directly converted into mechanical work within the engine itself, minimizing energy losses. In contrast, external combustion engines, like steam engines, have additional steps that lead to more energy losses. | Comments | Active | |

| 80 | In a vapour compression refrigeration system, the lowest temperature during the cycle is observed after: | evaporation | compression | expansion | condensation | c | VCRS cycle shown below .the lowest temperature (t2) is after the expansion process. |

Comments | Active | |

| 81 | Which of the following forced convection evaporator units have a discharge air rate from 60 m/min to 90 m/min? | Defrosting evaporators | Low velocity cooling forced convection evaporators | Frosting evaporators | High velocity cooling forced convection evaporators | b | Forced Convection Evaporators: Forced convection evaporators are used in refrigeration systems to enhance the heat transfer process by using fans or blowers to force air over the evaporator coils. These units are categorized based on the velocity of air they discharge, which can significantly affect their performance and application. There are two primary types of cooling forced convection evaporators based on air velocity: 1. High Velocity Cooling Forced Convection Evaporators: These evaporators discharge air at a high velocity, typically above 90 m/min. They are used in applications where rapid cooling is required and where air distribution over a larger area is necessary. 2. Low Velocity Cooling Forced Convection Evaporators: These evaporators discharge air at a lower velocity, typically ranging from 60 m/min to 90 m/min. They are suitable for applications where gentle cooling is needed, such as in storage rooms for fruits and vegetables to prevent dehydration. Important Points Low velocity cooling forced convection evaporators are specifically designed to maintain a discharge air rate from 60 m/min to 90 m/min, making them ideal for applications requiring controlled and gentle air flow. |

Comments | Active | |

| 82 | Brake power involves determination of the: | torque and angular speed of the shaft | inertia and displacement of the shaft | piston indicator | pressure and piston displacement | a | Brake Power (BP): Brake power is the power output of an engine measured at the engine's output shaft. It is the actual power available for work after overcoming the engine's internal friction and other losses. To determine the brake power, we need to measure the torque and the angular speed of the shaft. Torque (T): Torque is a measure of the rotational force applied to the engine's output shaft. It is usually measured in Newton-meters (Nm) or pound-feet (lb-ft). Angular Speed (ω): Angular speed is the rate at which the engine's output shaft is rotating. It is usually measured in radians per second (rad/s) or revolutions per minute (RPM). The formula to calculate brake power (BP) is: BP = T × ω Where: T is the torque. ω is the angular speed. MIE Trick to Remember:-  |

Comments | Active | |

| 83 | For the given overall heat transfer coefficient and temperature difference, if the area of evaporator surface increases, then the capacity of evaporator: | can increase or decrease | remains constant | decreases | increases | d | The capacity of an evaporator is directly related to the heat transfer rate, which depends on the overall heat transfer coefficient, the temperature difference, and the surface area of the evaporator. The heat transfer rate (Q) in an evaporator can be described by the equation: Q = U ⋅ A ⋅ ΔT For the given overall heat transfer coefficient and temperature difference, if the area of the evaporator surface increases, the heat transfer rate Q will increase proportionally because Q is directly proportional to the area A. If the area of the evaporator surface increases, then the capacity of the evaporator: This is because a larger surface area allows for more heat to be transferred, thus increasing the evaporator's capacity to absorb heat. |

Comments | Active | |

| 84 | If is gross stage efficiency; is blade efficiency and is nozzle efficiency of a steam turbine, then which of the following relations is correct? \(η_{gs}\) \(η_{b}\) \(η_{n} \) | \(η_{gs}= \frac{η_{b}}{η_{n}}\) | \(η_{gs}= η_{b}×η_{n}\) | \(η_{gs}= \frac{η_{n}}{η_{b}}\) | \(η_{gs}= η_{b}\) | b | Gross or Stage Efficiency: It is the ratio of work done on the blades per kg of steam to the total energy supplied or heat drop per stage per kg of steam. It is also defined as the product of Blade efficiency and Nozzle efficiency. \(η_{gs}= η_{b}×η_{n}\) |

Comments | Active | |

| 85 | The difference between the total head at the outlet of a centrifugal pump and the total head at the inlet of a centrifugal pump is called ________________. | suction head | static head | dynamic head | manometric head | d | Manometric Head: The manometric head is the total head developed by a centrifugal pump. It is the difference between the total head at the outlet (discharge head) and the total head at the inlet (suction head) of the pump. This head is responsible for the actual energy imparted to the fluid by the pump to overcome the resistance of the system. Mathematically, manometric head (Hm) can be expressed as: Hm = Hd - Hs Where: Hd : Total head at the discharge side Hs : Total head at the suction side |

Comments | Active | |

| 86 | Consider an air standard cycle in which the air enters the compressor at 1.0 bar and 20°C. The pressure of air leaving the compressor is 5 bar and the temperature at the turbine inlet is 600°C. For 1 kg of air, determine the efficiency of the cycle: | 35% | 25% | 30% | 32% | c | Initial pressure at compressor inlet, P1= 1.0 bar Initial temperature at compressor inlet, T1 = 20° C = 293K Pressure at compressor outlet, P2= 3.5bar Temperature at turbine inlet, T3 = 600 °C = 873K Specific heat ratio, = 1.4 \(γ \) Calculate the temperature after compression ( T2) : \(T_{2}= T_{2} (\frac{P_{2}}{P_{1}})^{\frac{γ-1}{γ}}=293(3.5)^{0.2857}≈420K\) Calculate the temperature after expansion (T4) : \(T_{2}= T_{3} (\frac{P_{1}}{P_{2}})^{0.2857}=87(\frac{1}{3.5})^{0.2857}≈608K\) Efficiency calculation: Using the temperature, the efficiency can also be given by \(η=1= \frac{T_{4}-T_{1}}{T_{3}-T_{2}} =1 \frac{608-293}{873-420 }=1-\frac{315}{453}=1-0.685 ≈0.305≈30.5%\) The efficiency of the Brayton cycle is approximately 30.5% |

Comments | Active | |

| 87 | In which of the following turbines, the ends of the blades are welded to disks to form a cage like a hamster cage and instead of the bars, the turbine has the trough-shaped steel blades? | Pelton turbine | Cross-flow turbine | Kaplan turbine | Francis turbine | b | - Cross-Flow Turbine Definition: A cross-flow turbine, also known as a Michell-Banki turbine, is a type of water turbine where the water flows across the blades rather than in the direction of the turbine's axis. This design allows the turbine to handle low head and high flow conditions effectively. The unique feature of the cross-flow turbine is its cage-like structure, where the ends of the blades are welded to disks, forming a structure reminiscent of a hamster cage. Instead of bars, the turbine has trough-shaped steel blades that capture and direct the water flow. |

Comments | Active | |

| 88 | Which of the following is NOT a function of lubricating oils used in refrigerants? | Transferring heat from the crank-case to the compressor | Sealing the gas between the suction and discharge ports | Decreasing the coolant temperature and hence increasing COP | Minimising friction | c | Lubricating oils do not directly decrease the coolant temperature or increase the Coefficient of Performance (COP) of the refrigeration system. These functions are primarily achieved through the refrigerant and the system's design and operation. | Comments | Active | |

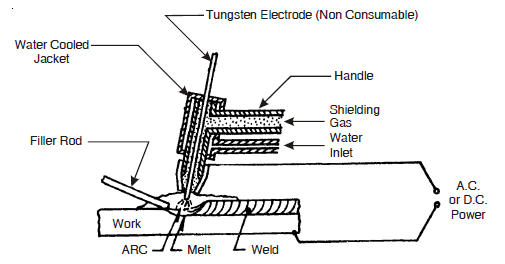

| 89 | Which shielding gas is commonly used in TIG welding? | Hydrogen | Carbon dioxide | Argon | Oxygen | c | Gas Tungsten Arc Welding, (GTAW). GTAW is also called as Tungsten Inert Gas Welding (TIG). The arc is maintained between the workpiece and a tungsten electrode protected by an inert gas. The electrode is non consumable since its melting point is about 3400°C. The arc tempe-rature may be in the range of 10,000 K. Here only one option as inert gas i.e argon  |

Comments | Active | |

| 90 | What is the purpose of a pattern in the casting pattern procedure? | To clean the mould before casting | To create the mould cavity | To remove the casting from the mould | To pour molten metal into the mould cavity | b | A pattern is an element used for making cavities in the mould, into which molten metal is poured to produce a casting. It is not an exact replica of the casting desired. There are certain essential differences. It is slightly larger than the desired casting, due to the various allowances (shrinkage allowance, machining allowance etc.) and it may have several projections or bosses called core prints. It may also have extensions to produce runners and gates during the moulding process. (Reference: A textbook of production technology by p.c.sharma – page no.-84-85) |

Comments | Active | |

| 91 | In case of two-stroke petrol engines, if exhaust gases do NOT leave the cylinder, then: | fresh charge gets diluted and efficiency of the engine decreases | fresh charge gets diluted and efficiency of the engine remains unchanged | fresh charge gets diluted and efficiency of the engine increases | fresh charge gets diluted and performance of the engine increases | a | Two-Stroke Petrol Engine: A two-stroke engine completes a power cycle with two strokes of the piston during only one crankshaft revolution. It uses ports for intake and exhaust instead of valves. In a two-stroke petrol engine, the exhaust gases are expelled from the cylinder to make room for the fresh charge (a mixture of air and fuel) to enter. If the exhaust gases do not leave the cylinder, it leads to the dilution of the fresh charge. Effects of Diluted Fresh Charge: When the fresh charge gets diluted with exhaust gases, the concentration of oxygen in the mixture decreases. This results in incomplete combustion of the fuel, leading to a reduction in the engine's power output. As a consequence, the overall efficiency of the engine decreases. |

Comments | Active | |

| 92 | What is the order of temperature generated at the anode during arc generation in electric arc welding? | 4500°C | 6000°C | 3500°C | 2000°C | b | The temperature of an electric arc depends upon the type of electrodes between which it is struck. It is about 3200°C on the cathode and about 3900°C on the anode for carbon electrodes and 2400°C and 2600°C respectively for metal electrodes. The temperature may reach 6000 to 7000°C in the centre of the arc. (Reference:- A textbook of production technology By P.C.Sharma – page no.-340) |

Comments | Active | |

| 93 | the boiling point of refrigerant R-13 is __________. | – 81.4°C | - 107.7°C | + 86.6°C | - 157.5°C | a | Refrigerant Formula B.P F.P Tcr P cr Application Compressor Types R-11 CCl₃F +23.77 -111 198 43.78 AC (200–2000 tonnes) Centrifugal R-12 CCl₂F₂ -29.8 157.5 112 41.16 Window, automobile AC Reciprocating, Centrifugal, Rotary R-13 CClF₃ -81.5 -181 28.8 38.6 Low-temp refrigeration (up to -90°C) in cascades Reciprocating R-22 CHClF₂ -40.8 -160 96 49.37 Commercial AC Reciprocating, Centrifugal R-717 NH₃ -33.3 -77.8 133 114.24 VARS, industrial and commercial Reciprocating R-21 CHCl₂F 8.92 -135 178.5 51.68 — — R-500 78% CCl₂F₂ + CH₂CHF₂ -33.3 -159 105 43.5 Household and commercial AC Reciprocating |

Comments | Active | |

| 94 | What will be the average pressure in plate clutch when the axial force is 4 kN. The inside radius of the contact surface is 50 mm and the outside radius is 100 mm. Assume uniform wear. | 1.7 N/mm2 | 0.17 N/mm2 | 17 N/mm2 | 0.17 N/m2 | b | First, we need to calculate the mean radius (r). The mean radius (r) is the average of the inner and outer radii: r = (r1 + r2) / 2 Substituting the given values: r = (0.05 m + 0.1 m) / 2 r = 0.075 m Now, substituting the values into the formula for average pressure: p = 4000 N / (2 * π * 0.075 m * (0.1 m - 0.05 m)) p = 4000 N / (2 * π * 0.075 m * 0.05 m) p = 4000 N / (0.023561944901923447 m²) p ≈ 169.9 N/m² Converting to N/mm²: p ≈ 0.1699 N/mm² Rounding to two decimal places: p ≈ 0.17 N/mm² |

Comments | Active | |

| 95 | Determine the torsional rigidity of a hollow shaft of 200 mm external diameter and 150 mm internal diameter. Consider G = 90 GPa. | 10.25 × 1012 N-mm2 | 10.25 × 1013 N-mm2 | 12.46 × 1013 N-mm2 | 9.66 × 1012 N-mm2 | d | Given that: do = 200 mm di = 150 mm G = 90 × 10³ N/mm² Polar moment of inertia (J) is given by: \(J = \frac{π (do^{4}- di^{4})}{32}\) Substituting the values: J = \(\frac{π(200^{4}- 150^{4})}{32}\) J = 1.072 × 10⹠mmⴠTorsional Rigidity (GJ) is calculated as: GJ = G × J = 90 × 10³ × 1.072 × 10⹠= 9.66 × 10¹² N·mm² |

Comments | Active | |

| 96 | The ratio of the actual brake thermal efficiency obtained from an engine to the theoretical efficiency of the engine cycle is called: | brake thermal efficiency | scavenging efficiency | relative efficiency | combustion efficiency | c | Relative Efficiency \(η_{rel}=\frac{Actual thermal efficiency}{Air standard efficiency}=\frac{η_{act}}{η_{air std}}\) MIE Trick to Remember:-  |

Comments | Active | |